1964 JAGUAR E-TYPE SERIES 1 3.8 RHD OTS

The brief for this garage-found 1964 Series 1 OTS was an end to end Restoration with sympathetic upgrades. Purchased in the US, the customer commissioned this rust free Californian beauty with matching numbers to be tastefully transformed in to a Gunmetal Grey roadster with contrasting Red leather interior.

Our starting point was to completely strip the tub and bonnet back to bare shell and to forensically inspect the car for any major repair works before being sandblasted. Once blasted, the team discovered that over the years repairs had been made to the sills and boot floor which needed replacing as a matter of course. Aside from these repairs the overall structure was sound enough to continue on to the next phase of panel work.

Coinciding with the panel work preparations, we had over 60 parts consisting of lower suspension, brackets and mounts individually powder coated and plated. Even Upper Wishbones were hand-machined to accept our Nylon upgrades. Our aim was - and always is with end-to-end Restorations - to retain as many original parts from the donor car as possible to avoid replacing with new what could potentially interfere with the cars historical connection or reliability.

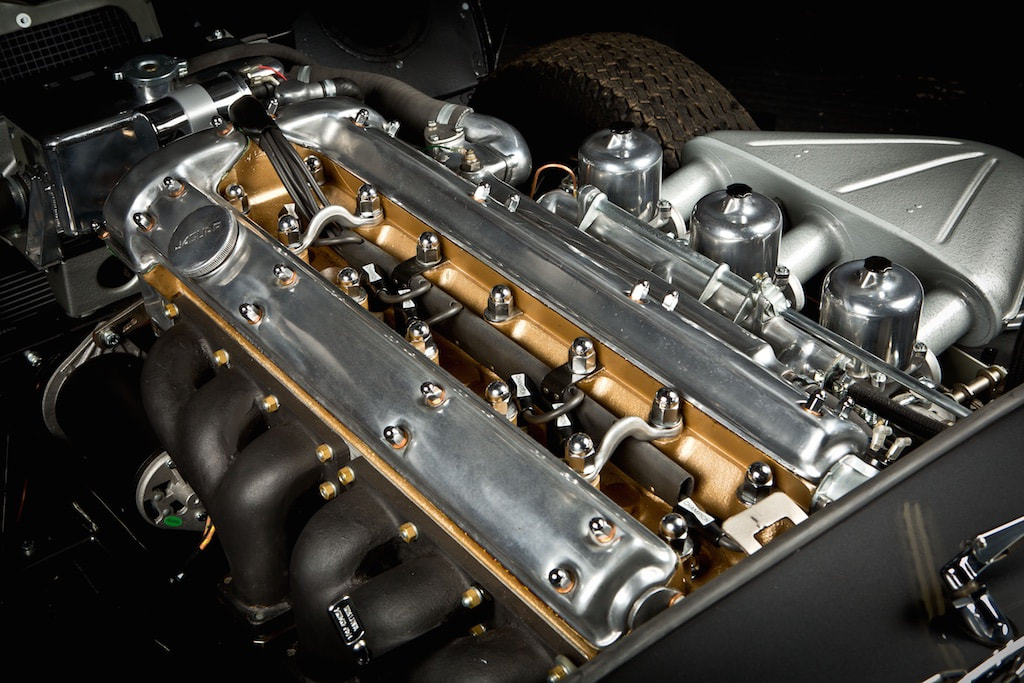

During the strip stage the team also arranged for the original engine block and carbs to be fully refurbished to standard specifications, and the rear axle was completely re-built with a new diff ratio of 3.06 to provide relaxed cruising for the customer. Even down to the bezels on the instrument panel to the fuel tank, stripping and powder coating was essential. Replacing the inner workings of the gauges was necessary but the original casings were built in so the instruments all matched beautifully.

Coinciding with the panel work preparations, we had over 60 parts consisting of lower suspension, brackets and mounts individually powder coated and plated. Even Upper Wishbones were hand-machined to accept our Nylon upgrades. Our aim was - and always is with end-to-end Restorations - to retain as many original parts from the donor car as possible to avoid replacing with new what could potentially interfere with the cars historical connection or reliability.

During the strip stage the team also arranged for the original engine block and carbs to be fully refurbished to standard specifications, and the rear axle was completely re-built with a new diff ratio of 3.06 to provide relaxed cruising for the customer. Even down to the bezels on the instrument panel to the fuel tank, stripping and powder coating was essential. Replacing the inner workings of the gauges was necessary but the original casings were built in so the instruments all matched beautifully.

Involved in the panel work stage the team switched their focus to the under panels where these were etch primed, a new door skin was fitted to the LHS, and the entire RHS rear quarter was completely cut out to have new panels welded in its place. At this stage the door gaps weren't completely perfect so prior to the primer phase these were accurately tightened.

We work personally with each customer on their restorations so that they are involved at each stage of the process. We showed the customer the progress that was being made whilst it was in the gapping stage. Our customers know E-Types so it was important that we had his input whilst we were adamant that the panels all fitted correctly. It was also at this point in the project that we converted the car to RHD from its American spec LHD.

With the newly re-conditioned engine, re-built carbs, and rear axle awaiting to be re-united with the body shell, the trial fitting of the bonnet and chrome could now commence. The tub is at 90% completion at this point and any adjustments to the bonnet gapping and trial fitting is carried out now ahead of the timely filling, flatting and primer stage.

We work personally with each customer on their restorations so that they are involved at each stage of the process. We showed the customer the progress that was being made whilst it was in the gapping stage. Our customers know E-Types so it was important that we had his input whilst we were adamant that the panels all fitted correctly. It was also at this point in the project that we converted the car to RHD from its American spec LHD.

With the newly re-conditioned engine, re-built carbs, and rear axle awaiting to be re-united with the body shell, the trial fitting of the bonnet and chrome could now commence. The tub is at 90% completion at this point and any adjustments to the bonnet gapping and trial fitting is carried out now ahead of the timely filling, flatting and primer stage.

The team can now cast their eyes over the entire shape of the car to see where the classic lines and contours need attention. This can be a lengthy process consisting of "fill, flat, fill, flat" but once complete the accurate, curvaceous shell is the perfect base for the primer and finally the paint.

Much to the technicians delight the customer opted for an understated, "seen but not heard" combination of Jaguar Original Opalescent Gunmetal Grey with a deep Red Leather interior. Now with the gaps and lines matching up beautifully, the shell was now ready for painting. This is always a poignant moment in any Restoration when the car finally starts to acquire an identity, and is also a perfect opportunity for the customer to witness the car of their dreams coming to life.

Upgrades were now at the fore-front of the customer's mind. Agreed upon and fitted following its return from the paint shop, was an up-rated vented front brake disc kit, aluminium header tank, and Marston radiator replica for enhanced cooling. A new Dynator Alternator was also installed for more powerful and reliable charging. The Engine was now ready to be delicately placed back in the car which was executed perfectly by the Technicians with zero damage incurred to the Engine frames or bulkhead.

Now came the pleasing re-building phase. One element that we see as the "heart of the car" is the original chassis plate. This is always re-fitted, along with the original body number plate in the inner wing of the boot, to retain the cars true identity. Even down to the infamous "Trico" stencil on the vacuum tank, which was lost, was re-painted as a nod to the original factory standards. This is the part of the project that takes time and patience - both with the Technicians and the customer. Delicate tasks such as laying in the wiring looms are carried out ahead of attaching the rear axle, and finally marrying the shell up with the fully re-built Gearbox and gold painted Engine. At this stage the team had made sure the sub-frames and front suspension were in place so we could get the car rolling again.

Now came the pleasing re-building phase. One element that we see as the "heart of the car" is the original chassis plate. This is always re-fitted, along with the original body number plate in the inner wing of the boot, to retain the cars true identity. Even down to the infamous "Trico" stencil on the vacuum tank, which was lost, was re-painted as a nod to the original factory standards. This is the part of the project that takes time and patience - both with the Technicians and the customer. Delicate tasks such as laying in the wiring looms are carried out ahead of attaching the rear axle, and finally marrying the shell up with the fully re-built Gearbox and gold painted Engine. At this stage the team had made sure the sub-frames and front suspension were in place so we could get the car rolling again.

With the team happy with how it runs, now came the cosmetic phase of attaching the hood and calling in the Trimmer to install the sumptuous Red Leather interior. The seats were trimmed in a soft, Vaumol leather to original specification. With the seats now in place, the team could put some miles on the clock around the Hertfordshire countryside and the results didn't disappoint.

With the car now complete, all that was left to do prior to being delivered to the customer was to give it a final valet and professional detail. The outcome of this E-Type could have been very different had it lived out the rest of its days buried in that Californian garage. Fortunately thanks to our dedicated and skilled team, this car has now been handed a new lease of life and has secured many years of enjoyment and joyful memories for the customer.

As the main feature in the "Best of British" article, and used on the front cover of the December 2019 issue of Classic Cars magazine, the customer spoke about what life is like owning this fabulous 1964 Series 1 E-Type reflecting on the magical journey we embarked upon together.

DORDOGNE VALLEY TOUR - JULY 2024

"In early July we headed out on a 1 week trip to the Dordogne Valley in our ’64 E-Type 3.8 drophead. It was our first overseas trip since the car was restored by Angus and team in 2017, so it was long overdue.

Packing a drophead when you have fitted luggage for the boot and for behind the seats is easy – if it doesn’t fit in the bags then it can’t go. You can pack enough for 1 week for sure!

Overnight security was of paramount importance, seeing as one can break in with a pair of scissors. Chateaus seemed to be the best and most interesting option. We used Google Earth alongside Tripadviser to check out car park security/ location to find the best ones and the homework paid off. The 2 chateaus on the way down (Behen near Abbeville, Manoir Les Minimes in Amboise) had gates that were locked overnight. The one on the return journey (La Touanne near Orleans) was on a large estate in a very remote area – plus the owners let us park overnight in their private garage. In between we spent 4 nights at our friends’ house in a remote Dordogne village that also had locked gates. I slept well.

I had assembled all the recommended tools and spares listed on various posts on the Forum – but needed none of them. The car simply did not miss a beat. It was happy to just drive all day long – whatever the speed or traffic conditions. It consumed no oil and never once threatened to overheat (even in 30 degree midday heat in heavy, stop-start traffic resulting from a serious accident on motorway). Confidence-inspiring.

Our route (in hours) was half motorway and half rural A and B roads. The roof always down, so we usually kept to c.65mph on motorways. The payback was wonderful views of the scenery, the uninhibited soundtrack of that wonderful straight six and reduced buffeting. Most will know already that French roads are excellent and, apart from Paris and its surrounds, they are eerily traffic-free. Maybe this contributed to the car staying remarkably clean although I did remove the dead bug collection every evening, and the car was detailed before we travelled.

We found out the nice way that the French are every bit as enthused about classics as us Brits. Everywhere we went they loved the car. When we stopped in some remote villages we were soon surrounded by what seemed to be the entire population. On the weekend we saw small convoys of classics heading in the same direction. We looked online and saw that there were local classic car meetings that we could have dropped in on. That would have been fun, but we’d already organised other activities. We’ll know to look out for those next time.

The Dordogne itself is spectacular: clifftop castles, lazy rivers, medieval towns, stunning scenery. And the food and wine is to die for, of course. In truth, it’s a long old drive getting there and a couple more days would have been ideal.

Now. Where to go next year …."