1970 JAGUAR E-TYPE SERIES 2 4.2 RHD OTS

What started as a whistlestop workshop visit with an existing restoration customer of ours before returning home to Australia, ended up being a "I want one of your restorations" visit. Seeing first hand the level that we go to on every nut and bolt restoration, this particular customer left the workshop for the airport with firm instructions that we source a good, solid donor car so that he could embark on the same restoration journey, as many before him have made. This was where another restoration client came to the rescue with a good, solid car that we already knew about, and which we had carried out previous works on.

The deal was done and we welcomed another Series 2 drophead onto our restoration books. Originally distributed in New York by British Leyland, this ex US spec roadster started life on the roads of Oregon in heritage Primrose Yellow with a Black interior. Once completed, it will have been transformed in to an Opalescent Silver Grey beauty with a sumptuous Red interior. Previous works undertaken by us include a complete IRS rebuild with a diff ratio change to 3:31, and left to right hand drive conversion which will be perfect for the roads down under. Necessary upgrades like fresh air-conditioning, electric power steering, and a pair of our sensible sport seats will also be fitted paving the way for comfortable touring.

The deal was done and we welcomed another Series 2 drophead onto our restoration books. Originally distributed in New York by British Leyland, this ex US spec roadster started life on the roads of Oregon in heritage Primrose Yellow with a Black interior. Once completed, it will have been transformed in to an Opalescent Silver Grey beauty with a sumptuous Red interior. Previous works undertaken by us include a complete IRS rebuild with a diff ratio change to 3:31, and left to right hand drive conversion which will be perfect for the roads down under. Necessary upgrades like fresh air-conditioning, electric power steering, and a pair of our sensible sport seats will also be fitted paving the way for comfortable touring.

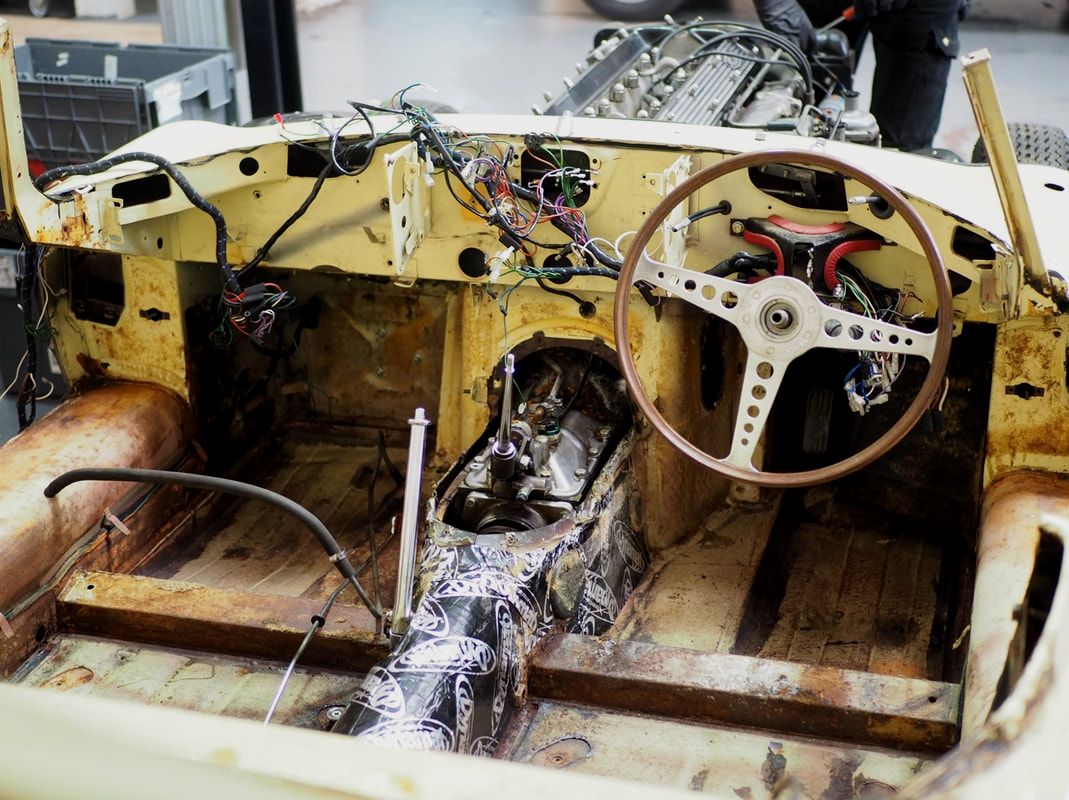

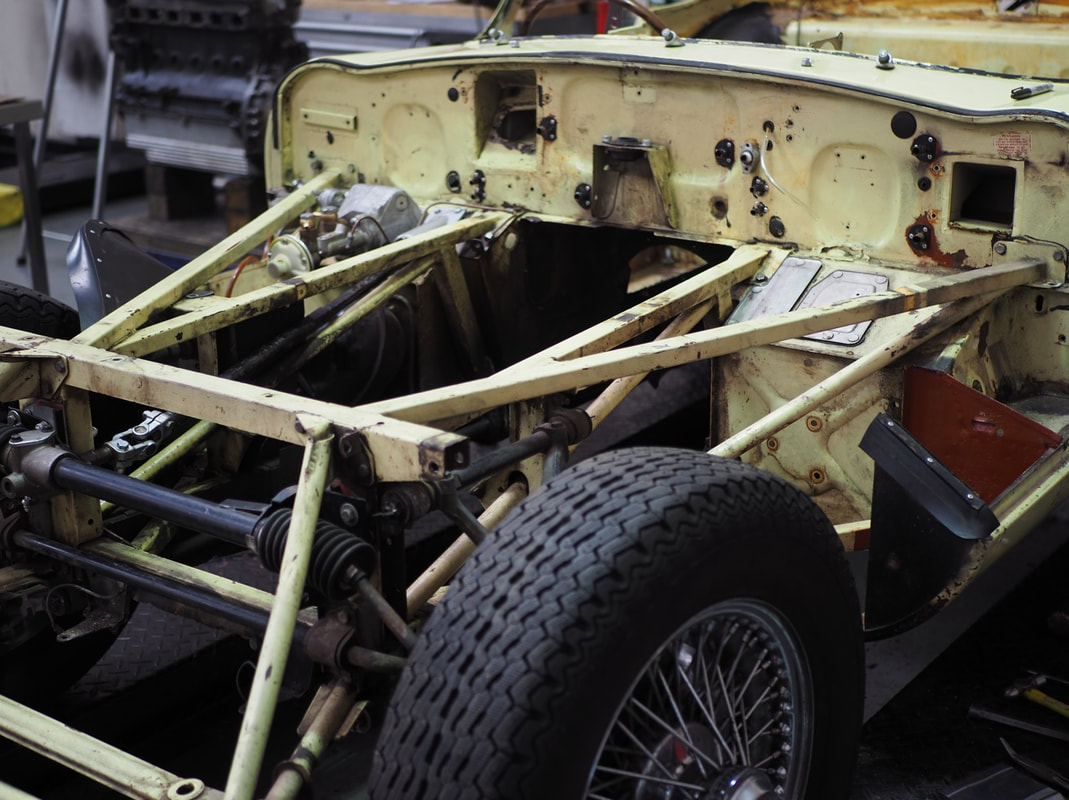

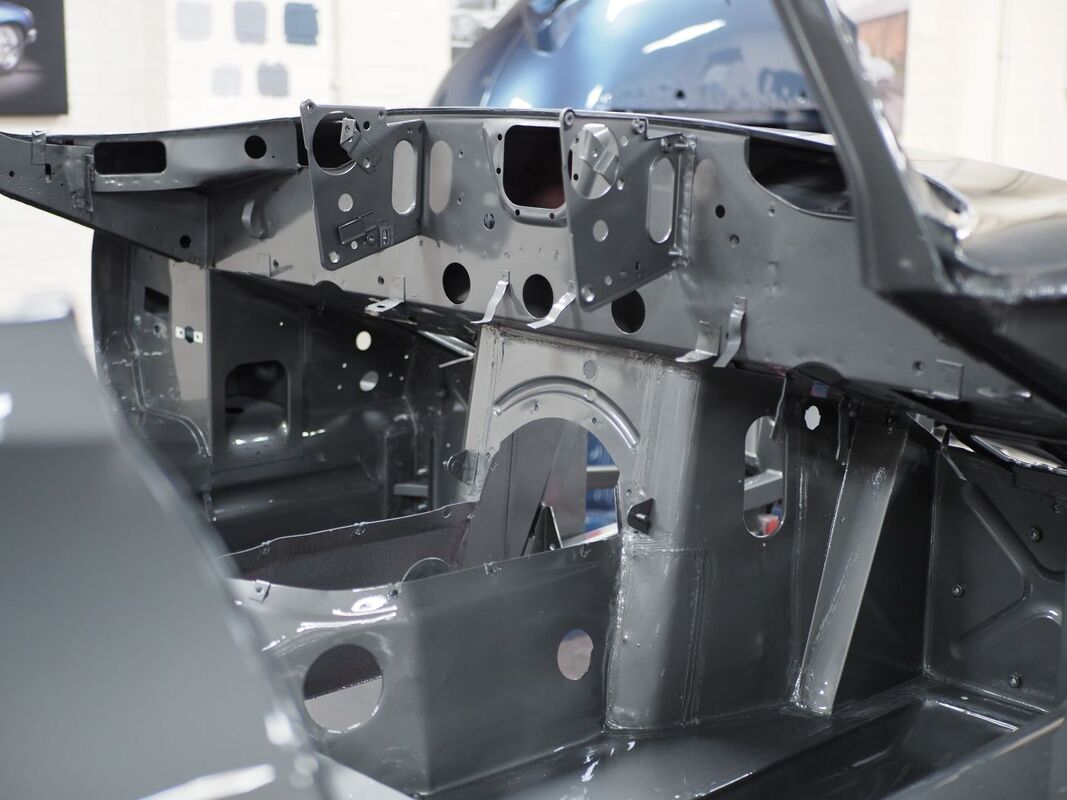

With the tub and bonnet panels now blasted and coated with a rust preserver, the Series 2 is finally ready to start the necessary repair works. Showing encouraging signs that the majority of the body is already in sound condition, the areas that are in obvious need of care are the dropped floors, cross member, A-posts, and the picture frame.

Knowing that the shell needed minimal repairs, the bodywork stage took next to no time to complete. The usual welding to holes that were either incorrect from previous repairs, not needed, or rust damaged were seen to first (NS and OS rear side repeater, rear panel, mirror holes in doors, boot floor and front wing repeaters). The aerial pole mounting was also erased to make way for a more modern, internal radio system, whilst the rusted off-side footwell was cut away and replaced with a new section.

Moving to larger areas on the body, both outer sills required some TLC with new panels replacing tired ones. Both the NS and OS lower wheel arch panel to sill sections, and lower bulkhead panel to sill sections all needed to be fabricated before being offered up to the shell, and local repairs were made to the under seat cross member. Once all the sill works were completed, both doors were checked for repairs before being hung and adjusted to achieve the correct sill fit.

Focus finally turned to the bonnet where the lower hinge panel needed necessary panel beating, and the upper hinge mounting points were removed and repaired. We could now fit the new set of specialised steel engine frames. We always replace any sets that come with the donor car with new as the flux used to braze on the frames tends to break down from the inside which over time would compromise the structure and ultimately the security of the engine. If repairable, we will always favour using the original picture and bonnet support frames to preserve originality and in this instance, we were able to panel beat and straighten the bottom edge of the picture frame.

Once assembled, the bonnet could be re-attached to carry out the all-important bonnet to bulkhead gapping. Adjustments were needed on the lower wing edges, and where the bulkhead meets the bonnet to attain the perfect lines.

Moving to larger areas on the body, both outer sills required some TLC with new panels replacing tired ones. Both the NS and OS lower wheel arch panel to sill sections, and lower bulkhead panel to sill sections all needed to be fabricated before being offered up to the shell, and local repairs were made to the under seat cross member. Once all the sill works were completed, both doors were checked for repairs before being hung and adjusted to achieve the correct sill fit.

Focus finally turned to the bonnet where the lower hinge panel needed necessary panel beating, and the upper hinge mounting points were removed and repaired. We could now fit the new set of specialised steel engine frames. We always replace any sets that come with the donor car with new as the flux used to braze on the frames tends to break down from the inside which over time would compromise the structure and ultimately the security of the engine. If repairable, we will always favour using the original picture and bonnet support frames to preserve originality and in this instance, we were able to panel beat and straighten the bottom edge of the picture frame.

Once assembled, the bonnet could be re-attached to carry out the all-important bonnet to bulkhead gapping. Adjustments were needed on the lower wing edges, and where the bulkhead meets the bonnet to attain the perfect lines.

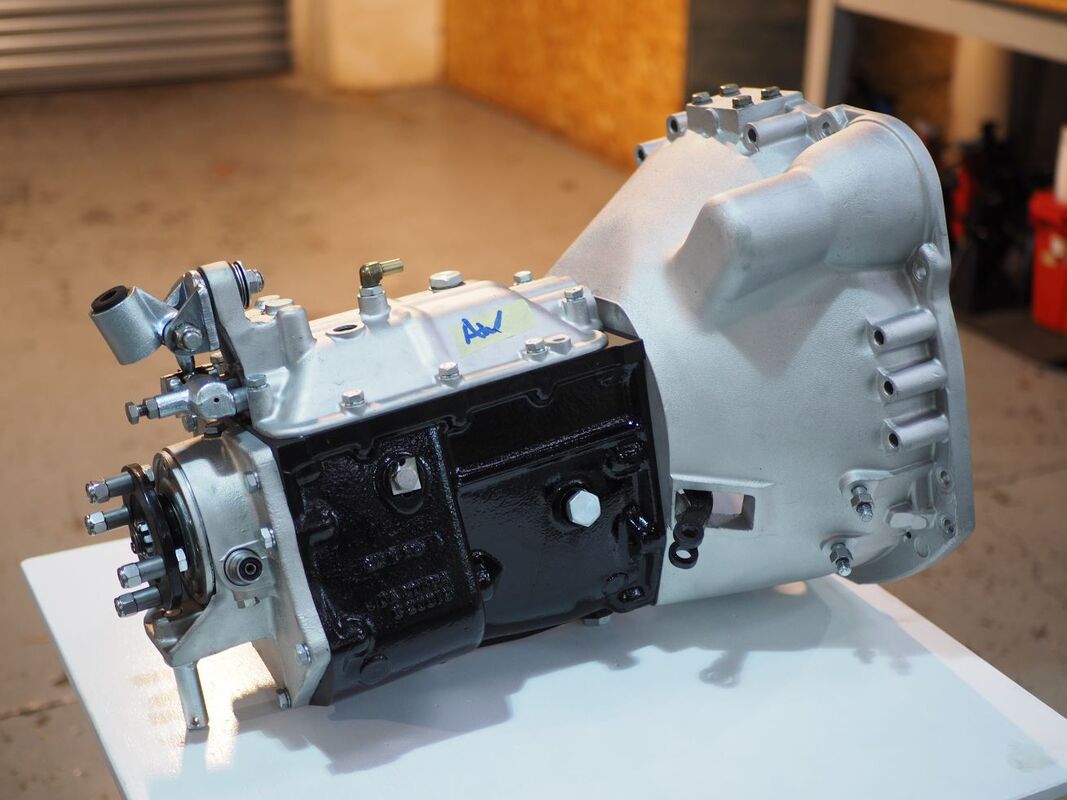

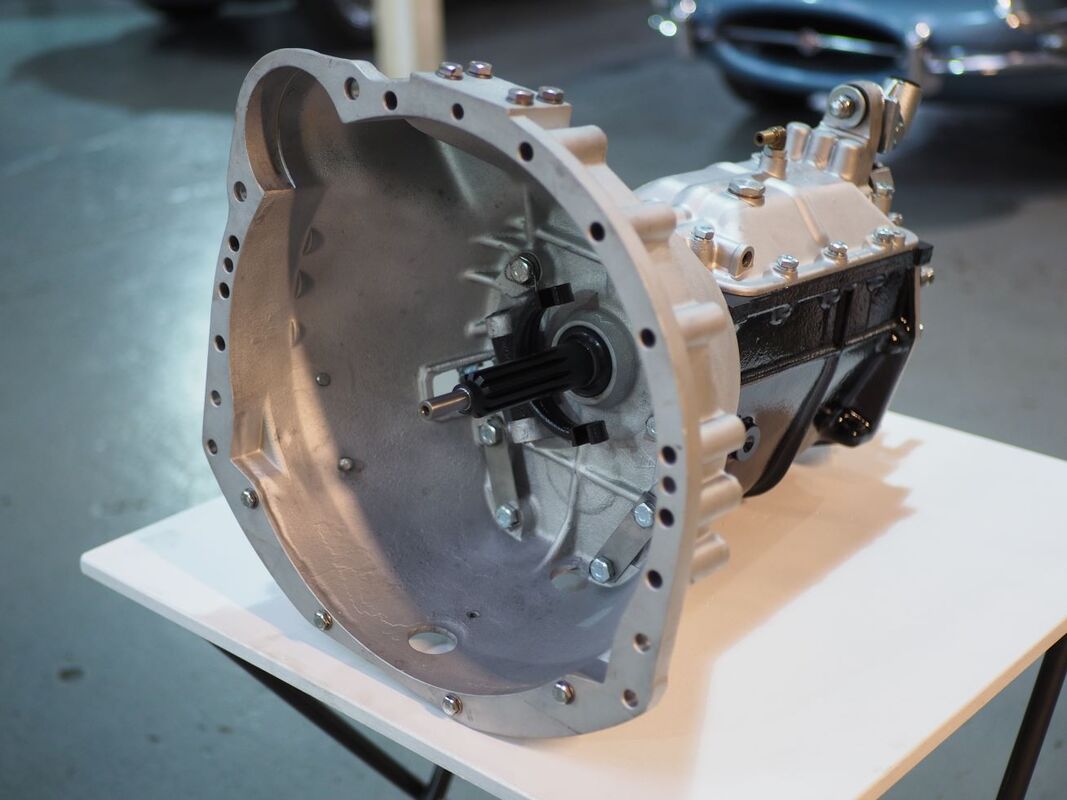

Like passing ships in the night, we handed the shell over to the skilled hands of the paintshop to transform into Opalescent Silver Grey as we received the overhauled gearbox back in to the workshop. Replacing bearings, needle rollers, layshaft, gaskets and seals as a rule of thumb, this particular rebuild also included some local repairs to the bellhousing and shaft ensuring many miles of Australian touring.

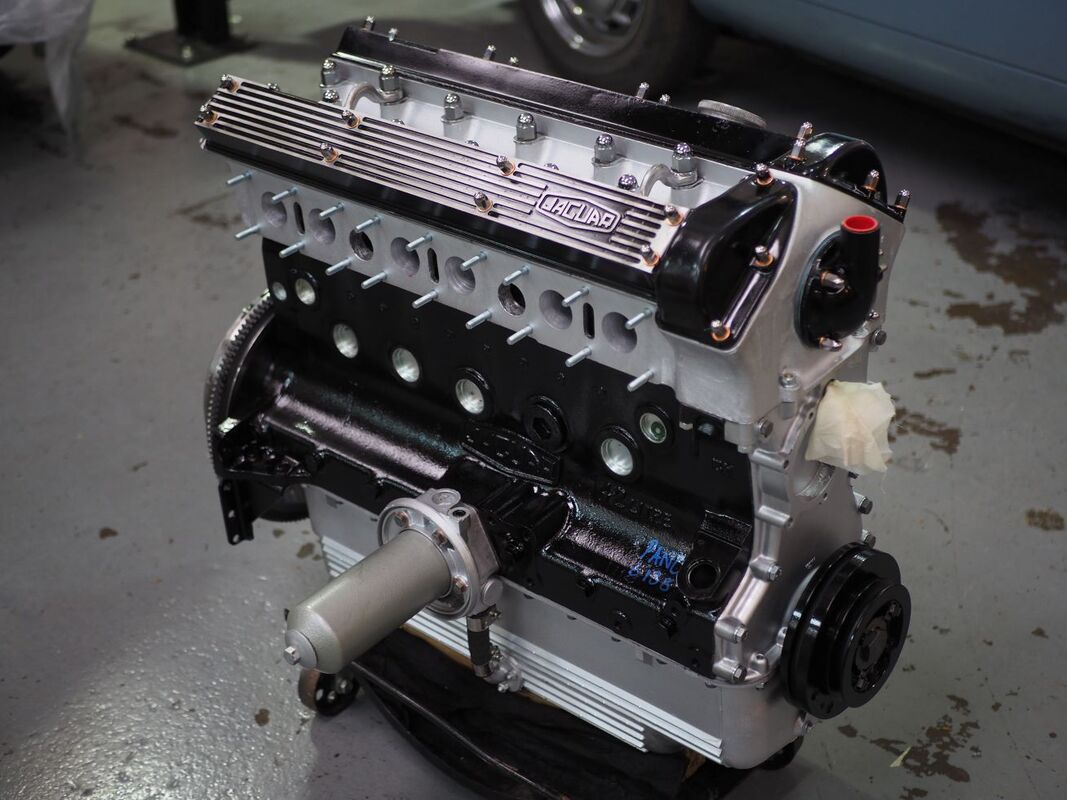

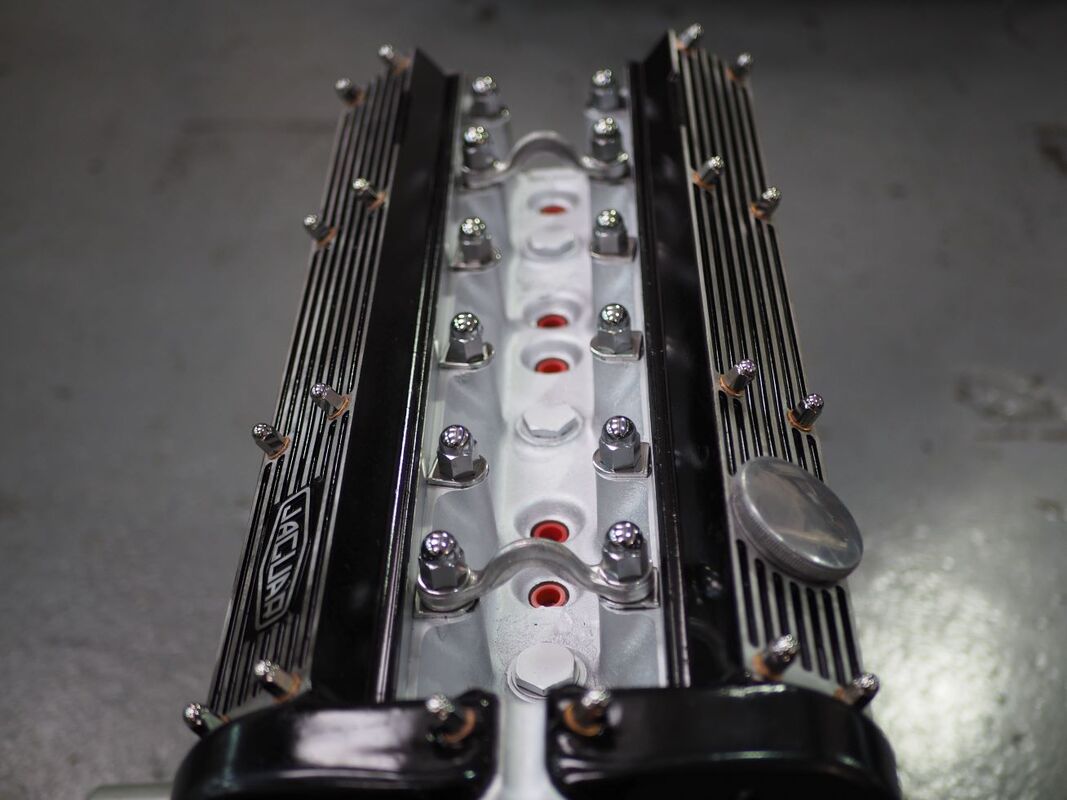

Knowing the car drove well from previous works, but unsure about it's last engine rebuild, we agreed with the client that an engine overhaul was a sensible idea given the car will eventually be residing in Australia. Now looking like a museum piece, our rebuilds usually consist of a rear oil seal conversion, full balance, a new clutch to replace the original, and a head stud kit. This particular block also needed both of its inner vernier gears replacing but with the original type.

Having carried out a full rebuild of the IRS system back in 2016 replacing main components with uprated (inner and outer fulcrum bearings, brake discs and pads, ARB bushes and mounts, radius arms etc), the customer was happy for us to give the unit a partial strip and thorough inspection before being reinstated.

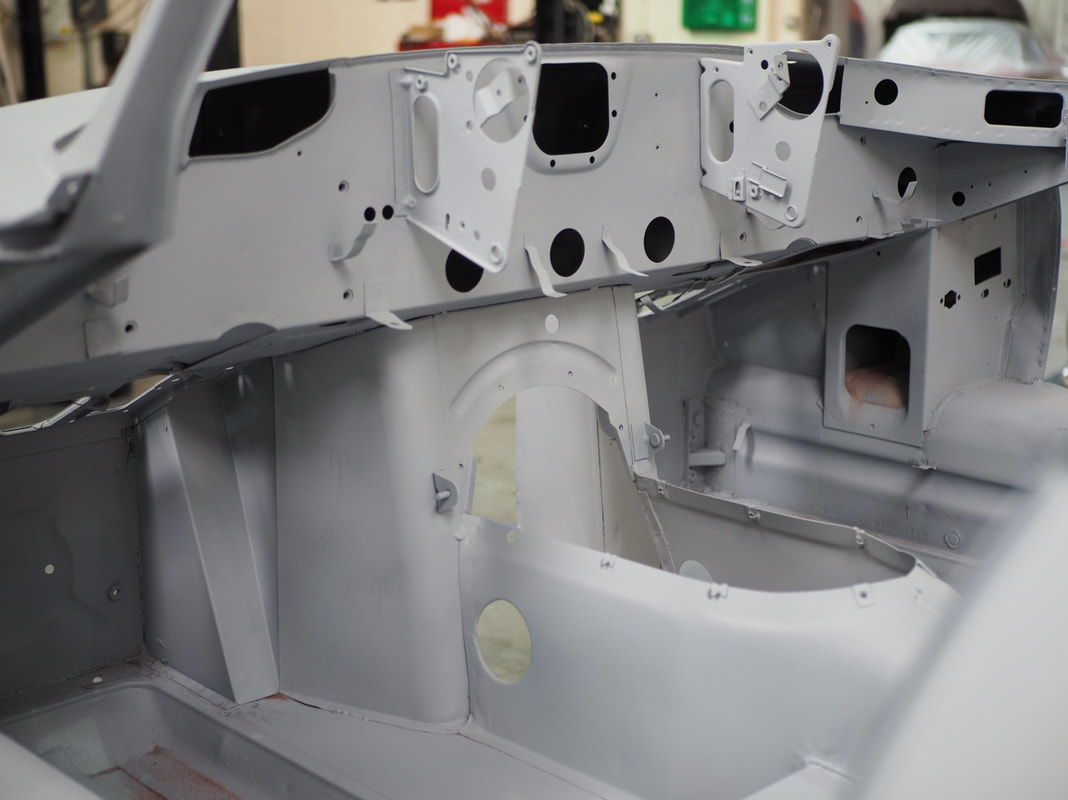

The time had finally come to show the client the first images from inside the paintshop. Their first tasks were to prep and prime all the door shuts to achieve that sharp edge once the car is in colour. More importantly, stone chip and sealer was applied before primed areas were flattened and Opalescent Silver Grey could be applied to the underneath, bulkhead and inside the cabin.

Because we want to achieve the highest quality possible when it comes to bodywork and paint, our attention to detail never diminishes during this critical stage in any restoration. Before the exterior of the shell was painted we noticed that we weren't 100% satisfied with the bonnet gaps so luckily we were able to make the necessary adjustments to get these looking sharp before the paint gun was loaded.

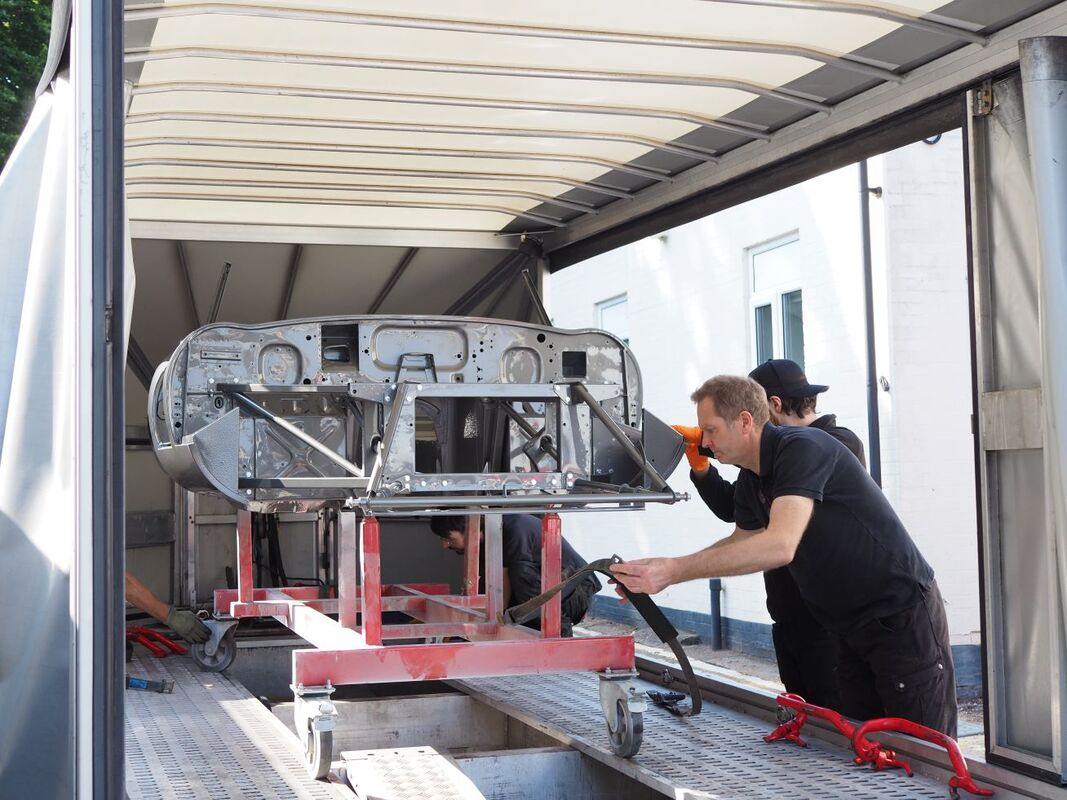

Just in time for the client's visit all the way from Australia, we welcomed the shell back to the workshop. With just a week to get as many components fitted to the car as possible before their arrival, we focused on building up areas of the front suspension with parts that had been rebuilt, nickel plated or powder-coated behind the scenes. We made the decision not to fit any sound deadening just yet as we wanted the customer to see the painted shell in all its glory.