1968 JAGUAR E-TYPE SERIES 2 4.2 RHD FHC

Sourced through our brokerage service, this rust free Texas-found 1968 Series 2 FHC was entrusted to us to have a full end-to-end restoration with continental specific touring upgrades. Destined to be an understated combination of Gunmetal Grey with a contrasting red leather interior, this project was special before it came through our doors. Prior to its current owner, this E-Type known as "Toby" was originally purchased by an eminent musician who sadly passed away and as a tribute to him the car now bears his name.

As with most of our cars, we take care in sourcing the most original, rust free cars as possible. Toby was a superb example of this. Having never been painted or welded since it left the factory in 1968 - and thankfully residing in the dry states of the US - the apprehensive task of stripping and cataloguing the Series 2 was more enjoyable than onerous.

Revealing its original factory body number inside the rear hatch, we always find the strip stage of a restoration so fascinating. The bodyshell, doors, rear hatch and stripped-down bonnet panels were delivered to the blasters. This is the stage of any restoration where the team can gauge the true structure of the body prior to the repairs and panel work.

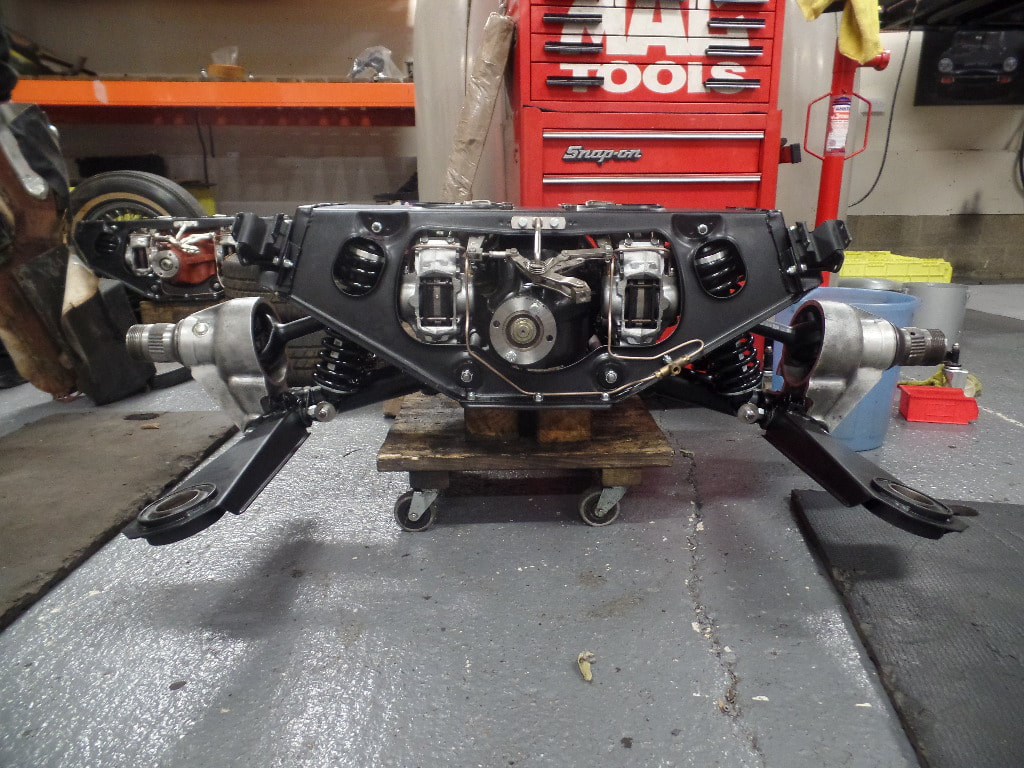

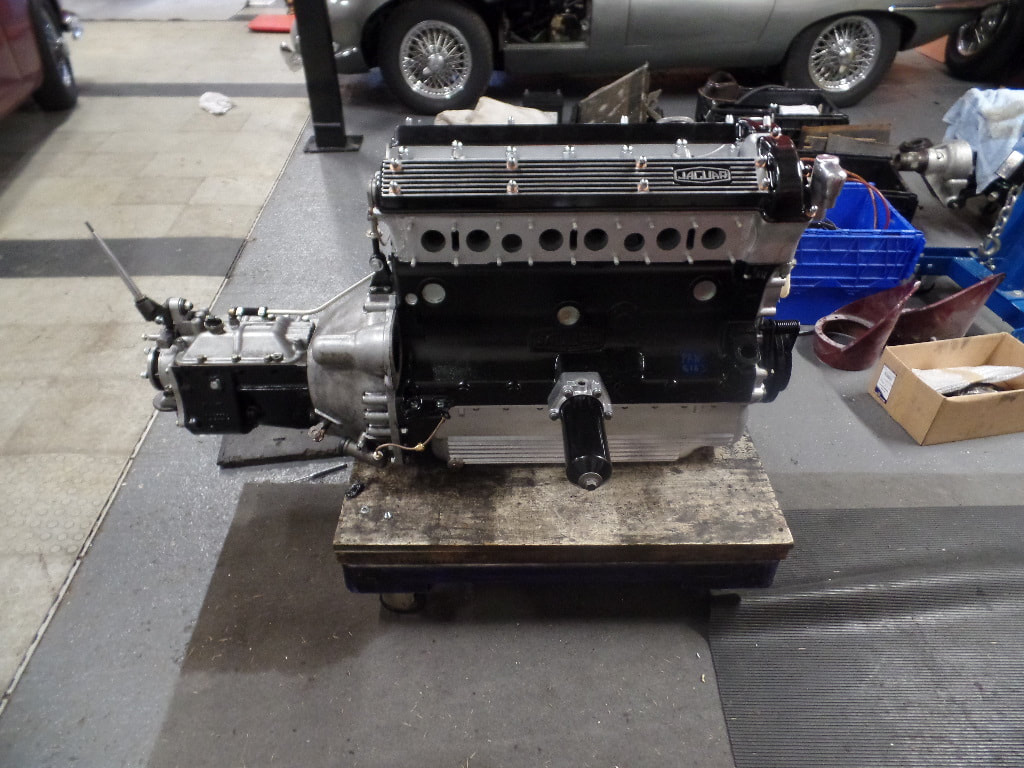

We favour blasting over stripping, but you have to work with a company that really understand the damage that can be caused to panels if blasted incorrectly. With the bonnet panels and tub with the blasting team, the focus turned to the strip down of the tired rear axle and delivering the 4.2 engine to be re-conditioned. As a matter of caution the brake calipers were split, cleaned, painted and fitted with new seals and pistons. The diff ratio was changed to 3.07 and the axle completely rebuilt following powder coating/plating where appropriate. All new bearings and UJ’s were fitted and the camber angles checked and shimmed correctly. With some damage found to the splines on one drive shaft, work was temporarily halted on the rear axle build, and the stripping of the Series 2 synchro gearbox commenced.

All brake and clutch lines are replaced as standard on every restoration we oversee. Cunifer replaces the original steel brake lines and are hand manipulated to an aesthetically pleasing level. We believe the components that are hidden away should look as good as the outside so high levels of care and attention to the finer details are upheld at all stages of the build.

Blasted in a fine grit and coated with a rust preserver, the tub and bonnet panels were now ready for the team to start the necessary repair works. Interestingly, we only changed the outer sills in order for us to have a look at the condition of the inner sills. The footwells were replaced due to denting, not rust. Small, localised repairs were made but overall, the structure was impeccable thanks to the dry US state where the car was discovered.

With the body almost ready for the paintshop, the engine was delivered back to the workshop following a full rebuild. Removing the bellhousing prior to the engine being sent away meant that all bushes were replaced with new along with a new clutch fork, pin and release bearing before being mated back up to the reconditioned engine. Converting the car to RHD was a priority for the customer which meant that the pedals needed bending.

Prior to painting, we always complete a dry build of the car. This means that all the chrome has to be fitted, and the doors, rear hatch and bonnet gapped to achieve the ideal lines. With the bonnet stripped to its bare components, it gives us the opportunity to paint in between the flanges and also weld up the Series 2 US spec side repeaters.

Prior to painting, we always complete a dry build of the car. This means that all the chrome has to be fitted, and the doors, rear hatch and bonnet gapped to achieve the ideal lines. With the bonnet stripped to its bare components, it gives us the opportunity to paint in between the flanges and also weld up the Series 2 US spec side repeaters.

Now with the bonnet finally built and fitted to the car, the team had some final shimming and adjustments to make prior to re-shaping the headlight apertures. The rear hatch fit was also now finalised and fitted with replacement hinges to solve the issues we were having with closing.

All gapped and ready for final filling and painting, we were able to build up the newly plated and rebuilt front suspension along with the uprights and rebuilt the brakes.

All gapped and ready for final filling and painting, we were able to build up the newly plated and rebuilt front suspension along with the uprights and rebuilt the brakes.

The final colour choice was heritage correct Gunmetal Grey, the first stage of the painting process was to stone guard and add body colour to the underneath of the floor pan. It is important that all the panels are painted externally at the same time in order to ensure an even cover. With the underside complete, the first noticeable area of the car to receive colour was the interior. Looking too beautiful to cover up with trim, the team were happy with the results and progressed to the outside of the car. This is always an exciting phase of the build both for us and the customer as we can really see the car take on its final identity.

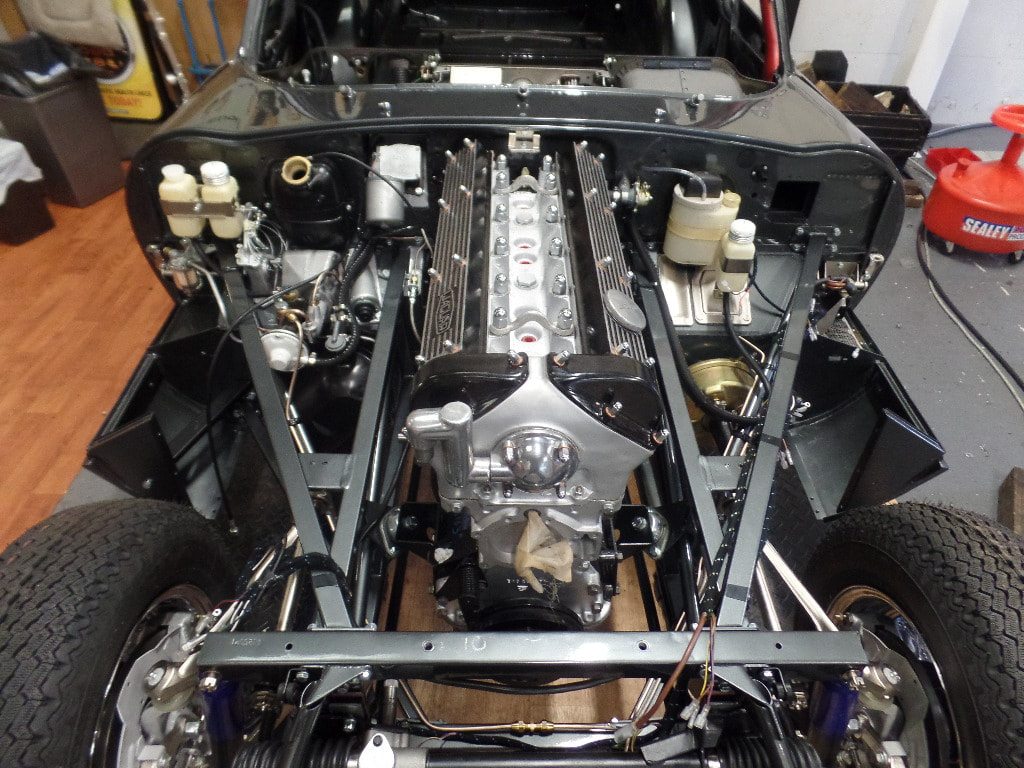

Back in our restoration bay from the paint shop, and carefully overseen by Murray, the meticulous and timely build could now commence. With every car we build, the first part to rightfully go back on the car is its original data plate. We believe that this is the heart of the car and should never be replaced with new wherever possible. With the engine frames attached, and the front suspension now in place, Murray's aim was to get the car back on its wheels as soon as possible.

The electrical system on 60’s cars was always regarded as unreliable now that we are 50+ years on. To counter this, we always fit new looms, new fuse boxes and strip, clean and test every switch. All of our cars are built with reliability at the forefront of our minds.

The electrical system on 60’s cars was always regarded as unreliable now that we are 50+ years on. To counter this, we always fit new looms, new fuse boxes and strip, clean and test every switch. All of our cars are built with reliability at the forefront of our minds.

Nearing the milestone engine installation, there was still a long list of tasks needing to be completed. The new wiring loom and dashboard were now in place and testing well so Murray was now faced with re-instating the completely rebuilt rear axle. The IRS was installed making way for the new set of competition wire wheels and original spec Dunlop Sport 185 tyres. Close to emerging from the restoration room, the team were able to start preparing the chrome work for re-fitting, and were also preparing the roof and cantrails for the fresh grey cloth lining.

Finally sitting on its suspension, and fully rolling, the stunning re-conditioned 4.2 engine could be married up. With the triple SU carburettors, steering rack, and re-cored radiator all in place, Murray now focused on fitting the radiator hoses, the powder coated and POR15 sealed fuel tank, and an upgraded alternator. All hydraulic lines would be bled using Silicone fluid before Murray could move on to building up the doors, installing the glass, and entering the trim phase.

The floor pan was stripped of old sound-deadening during blasting and replaced with modern Dynamat. It is important on our restorations that we ensure the cars are as quiet inside as possible. Little details like having matching keys is also essential. Installing rubbers takes a few hours as we have to shave them in places to ensure the doors close easily. We also restore the original heater box and fit an uprated (faster) heater fan.

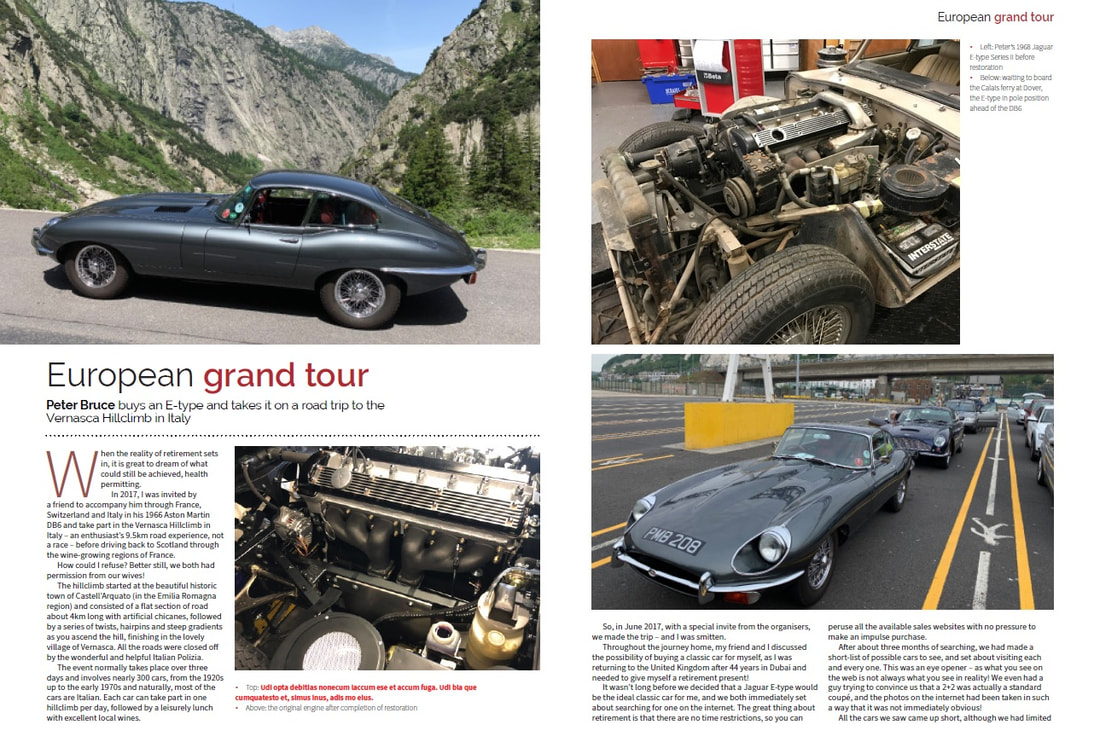

With the chrome starting to lift the car, the team were finally entering the last stages of the build with the arrival of the vinyl luggage boards and our sumptuous upgraded sport seats. So with the windscreen and heated rear screen in, we were finally ready to put some Hertfordshire miles on the clock. The Italy trip looming, Murray wanted to get a minimum of 100 miles on Toby before he could hand the keys over to the client.

With the chrome starting to lift the car, the team were finally entering the last stages of the build with the arrival of the vinyl luggage boards and our sumptuous upgraded sport seats. So with the windscreen and heated rear screen in, we were finally ready to put some Hertfordshire miles on the clock. The Italy trip looming, Murray wanted to get a minimum of 100 miles on Toby before he could hand the keys over to the client.

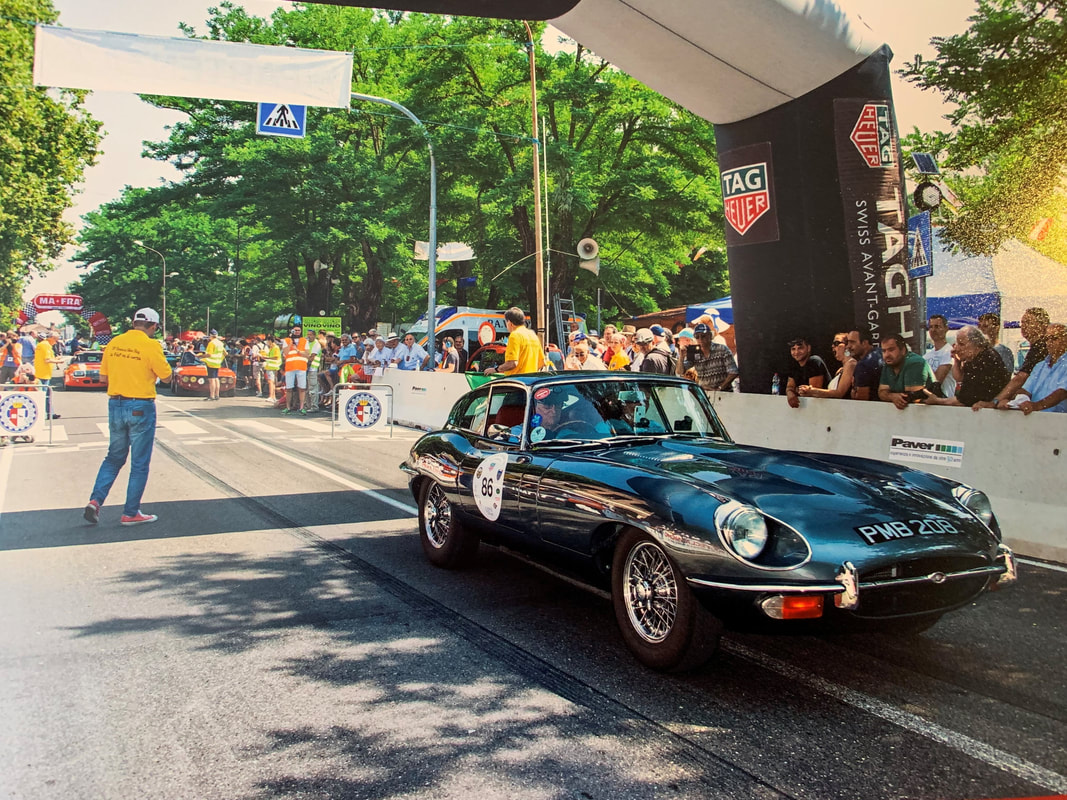

Driving beautifully with a successful MOT under its bonnet, the time had come to hand Toby over to its rightful custodian. Equipped to handle lengthy continental touring, and most importantly the Silver Flag Vernasca hill climb, the E-Type that Murray single-handedly built would be one of the most poignant, and emotional, builds we have ever achieved.

As a final compliment, and to immortalise Murray's impeccable work, Jaguar World's article entitled "Coming of Age" spoke about how young people today would rarely get an opportunity such as this, and re-iterated the skills and level of finish that Murray has absorbed whilst being part of the Moss Jaguar family.

February 2022 saw an in-depth article in The E-Type Club magazine, written by Toby's custodian himself, documenting the astonishing trip he made with a friend and their Aston Martin DB6 through France, Switzerland, and competing in the Silver Flag hill climb in the Vernasca hills.