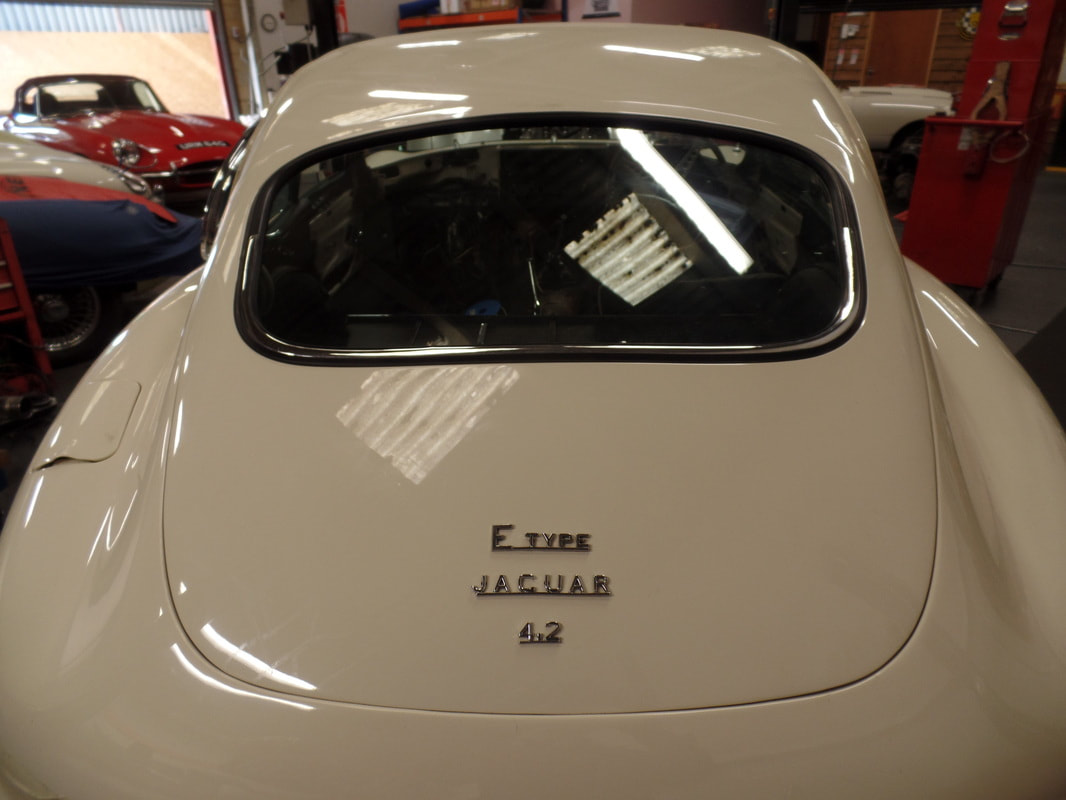

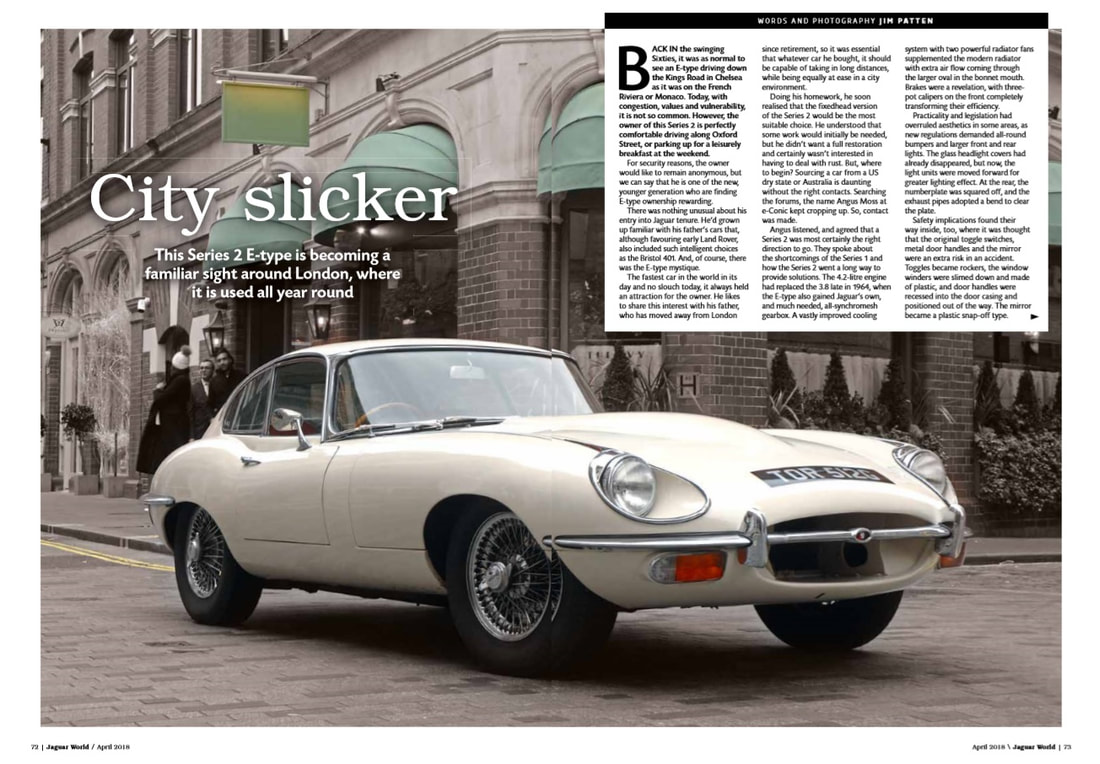

1969 JAGUAR E-TYPE SERIES 2 4.2 RHD FHC

Discovered in the ideal dry states of the US through our Brokerage service, this rust free 1969 Series 2 was the perfect donor car for re-commissioning. Still retaining the American specification, the customer's brief was to convert to RHD to withstand the streets of Kensington, and to repaint from bare metal back to the Jaguar original colour of Old English White.

Before the team could begin stripping the car, we needed to ascertain that the engine was sound. After discovering a new ignition switch had been fitted and incorrectly wired, a compression test eventually proved that the engine was fine and the initial stages of strip down could start.

First to be removed was the windscreen chrome and screen meanwhile both doors were stripped and the factory standard air-conditioning was removed. All rubber seals were scraped off, rear quarter lights and seats soon followed. Thanks to the cars rust-free and solid shell, the team were able to catalogue all aspects of the car without any difficulty.

First to be removed was the windscreen chrome and screen meanwhile both doors were stripped and the factory standard air-conditioning was removed. All rubber seals were scraped off, rear quarter lights and seats soon followed. Thanks to the cars rust-free and solid shell, the team were able to catalogue all aspects of the car without any difficulty.

The lengthy strip continued with the side chromes, rear bumper and rear lights all removed. The last part of the air conditioning was also taken off so the car was now ready for the conversion to RHD. All the original sound deadening surrounding the fuel tank was found to be in good condition once the luggage boards were removed.

The engine was eventually started and initially sounded OK. However during our heat cycle test it was discovered that the block was silted up. This would lead to a complete engine rebuild.

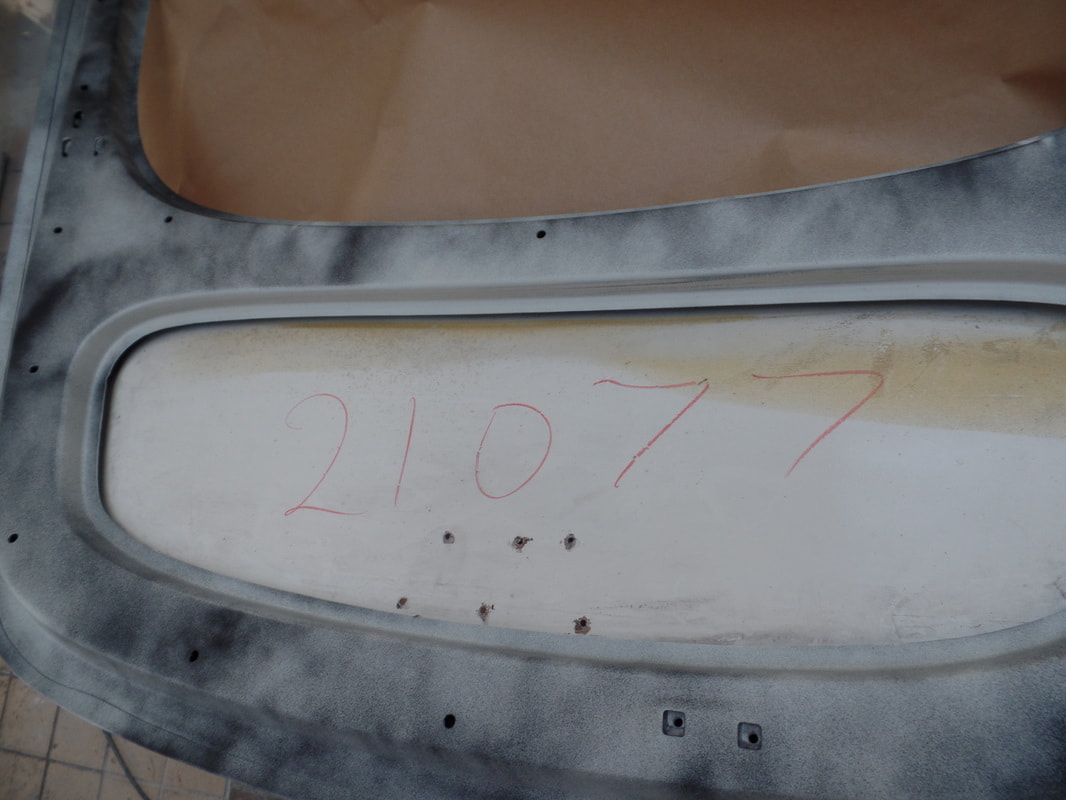

With the headlight scoops removed, we proved that the bonnet was the original one fitted by the factory mark on the inside of the scoop. This number also corresponded with the body number stamped on the chassis plate so already we were confident that this was a good example of an original car.

The engine was eventually started and initially sounded OK. However during our heat cycle test it was discovered that the block was silted up. This would lead to a complete engine rebuild.

With the headlight scoops removed, we proved that the bonnet was the original one fitted by the factory mark on the inside of the scoop. This number also corresponded with the body number stamped on the chassis plate so already we were confident that this was a good example of an original car.

Now the team could focus on stripping the old, mis-matched paint to get a closer look at what necessary repairs needed to be made. Sure enough we discovered that previous damage had been made to the bonnet as areas had been filled, and there were also the usual parking dents to contend with. Once in the panel beating stage, we also found that once the factory underseal had been removed it revealed a perfect boot floor. Even under the bonnet the wiring loom still bore its original round cardboard tag. With a few more battle scars and dents taken out of the footwells, the workshop were nearing the next phase of paint.

The car was now in etch primer and ready for the welding phase. All the side repeater holes were closed and the additional holes where the front number plate was held was also filled in. Some extra welding around the rear quarter panels and at the front of the foot wells was also needed. To achieve the best gaps the bonnet was completely re-shimmed. The car was now ready for primer.

During these almost surgical procedures being made to the car, we are constantly faced with retaining its true identity. By unearthing the original chinagraph markings made by the factory on the rear hatch, the team along with the customer made a unanimous decision to leave this section un-painted. Like with the cars original chassis plate, we feel that elements like this should remain untouched and act as a tribute to the cars historical background.

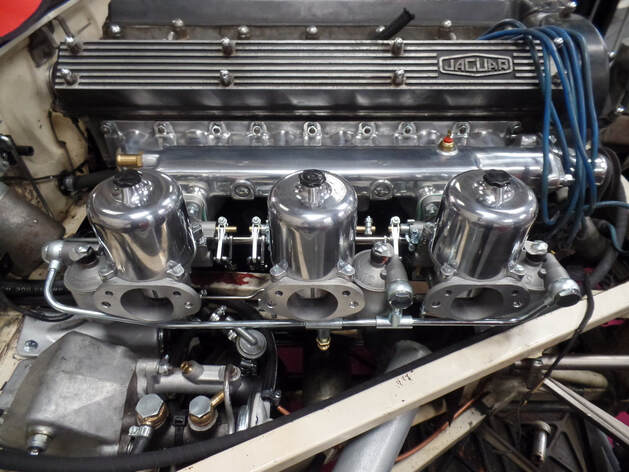

Now enrobed in original Jaguar Old English White we could now focus on the all important clean up under the bonnet. By powder coating and nickel plating specific components, installing the newly rebuilt engine, and attaching a new set of triple SU carbs, the engine bay was starting to shine.

As a necessary aspect of any re-commission project, and to improve the customers day-to-day driving, the front suspension was completely stripped and re-built before being re-instated on the car. Other components like the rebuilt heater box were fitted along with new bulkhead transfer pipes and steering column and rack.

With new vented discs fitted and the wishbones, steering rack, sub axles and brakes all connected up, the car was ready to sit back on all 4 wheels with the team now moving on to the interior and building up the outside of the car.

As a necessary aspect of any re-commission project, and to improve the customers day-to-day driving, the front suspension was completely stripped and re-built before being re-instated on the car. Other components like the rebuilt heater box were fitted along with new bulkhead transfer pipes and steering column and rack.

With new vented discs fitted and the wishbones, steering rack, sub axles and brakes all connected up, the car was ready to sit back on all 4 wheels with the team now moving on to the interior and building up the outside of the car.

Delivery of the re-trimmed original seats and centre console is always an exciting milestone. Upholstered back to the cars original classic Black leather gave it the fresh lift it needed from when it first arrived at the workshop. The original vinyl was still in perfect condition so following a deep clean from Murray, along with new foam, it was re-fitted with ease.

Moving on to the outside, both the rear quarter lights had been fitted along with the vacuum pipes and LHS mudguard. Given the phenomenal condition the car was in the guys were having no issues with the build up at this stage. The door locks were completely stripped and cleaned of the original sticky grease before being fully re-built and fitted back to the doors.

Moving on to the outside, both the rear quarter lights had been fitted along with the vacuum pipes and LHS mudguard. Given the phenomenal condition the car was in the guys were having no issues with the build up at this stage. The door locks were completely stripped and cleaned of the original sticky grease before being fully re-built and fitted back to the doors.

Starting this old girl up again wasn't far off so the boys main focus now was to finish off the meticulous wiring, strap and connect all the radiator hoses in place, and start to bolt up the chrome components.

With the dashboard in position - minus the glovebox at this stage of the build - we along with the customer were pleased with how well the car was progressing.

With the dashboard in position - minus the glovebox at this stage of the build - we along with the customer were pleased with how well the car was progressing.

The newly re-chromed components were starting to make the car come alive. To obtain a tight and neat fit we used a Series 1 thin bumper rubber around the rear bumper chrome, meanwhile new gearbox rubbers and heatshields were fitted.

The RHS instrument panel was now bolted down and the new choke and speedo cable were fully installed. As part of the cars service history, we found in the documentation that the Speedometer was completely refurbished in Hollywood back in 1973. Another reminder of the interesting history of the car. Back underneath, the larger than standard big bore stainless steel exhaust from Ecosse Motorsport was now fitted and looking stunning.

Finally, inside the car all the front carpets were in place along with the centre console. The electrics checked out successfully so all we had to do now was fire her up.

The RHS instrument panel was now bolted down and the new choke and speedo cable were fully installed. As part of the cars service history, we found in the documentation that the Speedometer was completely refurbished in Hollywood back in 1973. Another reminder of the interesting history of the car. Back underneath, the larger than standard big bore stainless steel exhaust from Ecosse Motorsport was now fitted and looking stunning.

Finally, inside the car all the front carpets were in place along with the centre console. The electrics checked out successfully so all we had to do now was fire her up.

The car was now about 90% complete with both doors now built up and rubbers glued in to position, more chromework back on the car, and final adjustments being made to the carbs and timing. The made-to-measure Pilkington windscreen was also not far off from being installed.

New silicone leads were fitted. Having chased down a lack of spark we finally managed to get the engine started. Finally running sweetly and the last of the carb tuning completed, we were already thinking ahead to her first road test but before we could put some Hertfordshire miles on the clock, we had to carry out a full rebuild of the rear axle and swapping to a 3:07 ratio differential.

New silicone leads were fitted. Having chased down a lack of spark we finally managed to get the engine started. Finally running sweetly and the last of the carb tuning completed, we were already thinking ahead to her first road test but before we could put some Hertfordshire miles on the clock, we had to carry out a full rebuild of the rear axle and swapping to a 3:07 ratio differential.

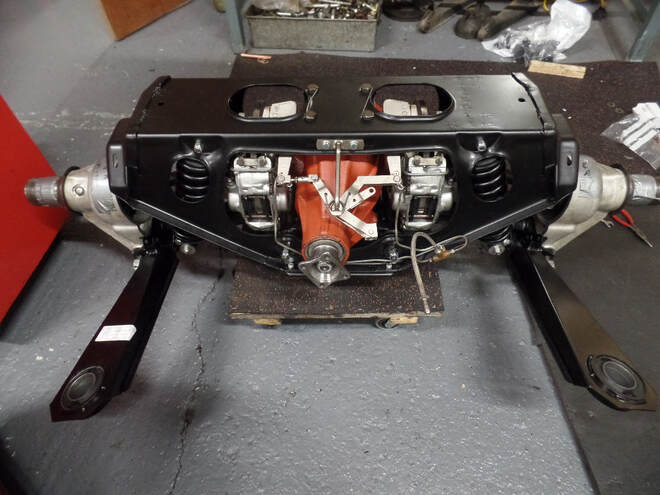

The intensive task of removing the rear axle for a full rebuild was well underway. During the strip stage we found that one of the handbrake adjuster screws had broken which led us to think what else could be faulty. As we catalogued and separated components destined for powder coating and nickel plating, the rear brake calipers were cleaned, rebuilt and painted before being re-attached.

Once the rebuilt diff bearing a new 3:07 ratio was delivered back to the workshop we could finally start the cage build ready for the shocks to go back in. New radius arms were the final flourish to complete the rear axle rebuild meaning we could now comfortably put some miles on the clock.

At long last we could take her out on road testing and get the necessary registration process started. With a few 100 testing miles under the bonnet, the time had come for this special old girl to be extensively detailed and polished in anticipation of the customer collecting.

Once the rebuilt diff bearing a new 3:07 ratio was delivered back to the workshop we could finally start the cage build ready for the shocks to go back in. New radius arms were the final flourish to complete the rear axle rebuild meaning we could now comfortably put some miles on the clock.

At long last we could take her out on road testing and get the necessary registration process started. With a few 100 testing miles under the bonnet, the time had come for this special old girl to be extensively detailed and polished in anticipation of the customer collecting.

Fully detailed and bound for the grand streets of Kensington, Jaguar World's Jim Patten took the opportunity to capture the car in its stomping grounds and talks about how the owner uses this as their everyday car around the city. Aptly titled "City Slicker" the article spoke about the rewarding journey that we embarked upon with the client, and how their commute to and from work will forever be an iconic and head-turning one.