1970 JAGUAR E-TYPE SERIES 2 4.2 LHD FHC

Delivered to us to part-way through the strip phase, this US sourced Series 2 has been entrusted to us to complete its nose-to-tail restoration. Specified by the customer to have the car transformed in to Metallic Flag Blue with Biscuit trim, the team have started the meticulous cataloguing stage of the strip down. With a looming completion deadline of June 2021, we are fortunate that some of the lengthy work has already been ticked off the list including all doors have been re-skinned, the 4.2 engine has been completely rebuilt, and all bright work re-chromed.

So as our 6th in-house restoration project picked up during a global pandemic, we are extremely excited to start this special journey with the customer as it is always one to remember.

So as our 6th in-house restoration project picked up during a global pandemic, we are extremely excited to start this special journey with the customer as it is always one to remember.

With such a tight completion date we were very quick to deliver the body shell to the blasters and today saw its safe return to the workshop and then straight off to panel works. Now with a clearer idea of what needs tackling on the shell, including all the usual problem areas, we are looking forward to getting the classic lines and curves back in to this later Series 2 example.

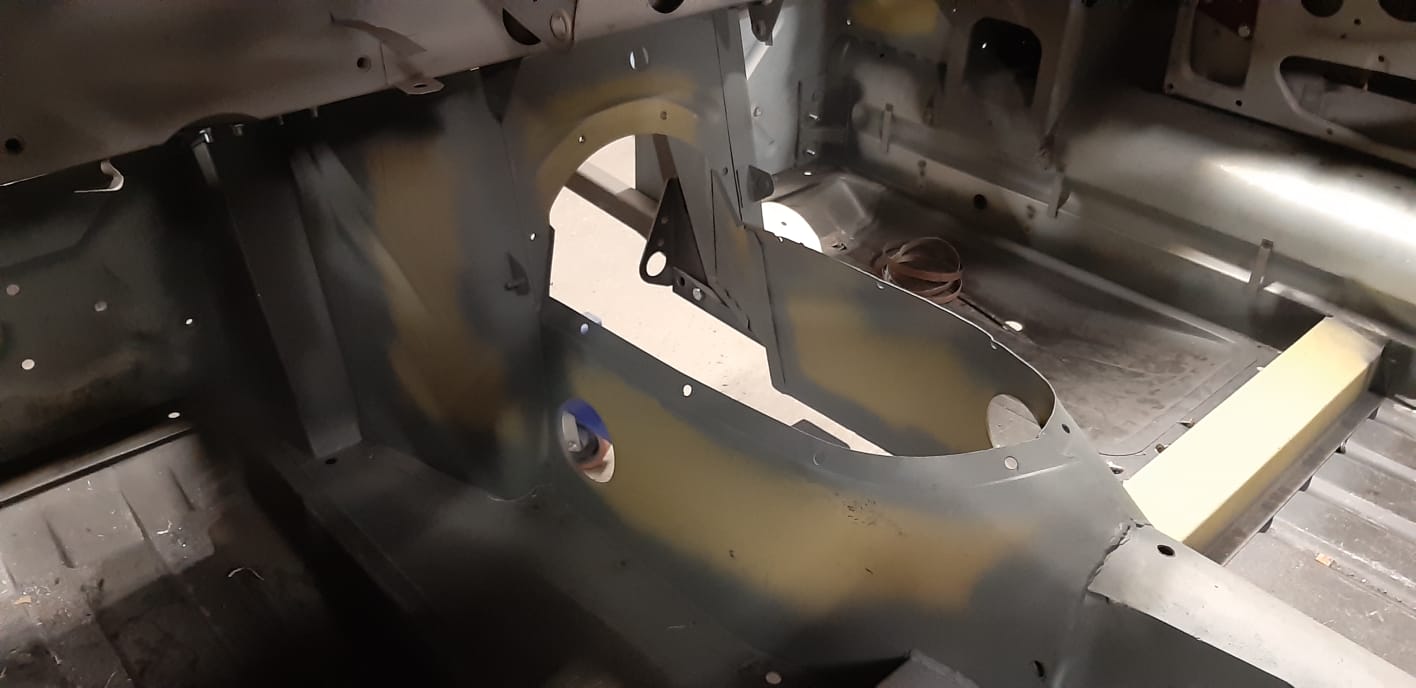

Finally with a bit of breathing space in the workshop following a couple of rather busy months, we took the opportunity to see how the panel guys were doing with the body of our Series 2 and they didn't disappoint! When we took on this project it was at the beginning of its body work stage but until we had the shell blasted we were unsure where to pick up where it was left off. Once we got it to the panel workshop we discovered that the floor pan that was previously in there hadn't been properly jigged up when it was fitted which meant that it was measuring off with the rest of the panels. Ultimately this would have meant that there would have been unnecessary tension in areas on the car which isn't ideal for its structure and shape. This then led us to making the decision along with the customer to replace the existing floor pan with new so all the edges had to be cleaned and repaired to take the new sections and back panels. The rear heel panel was repaired and the old bulk head panels were removed to replace new ones with seal closing panels, seal strengtheners, outer seals and bulk head side panels. Finally the transmission tunnel was removed and replaced with new.

Moving in to October saw the removal of the boot floor, the lower quarter and the number plate panel for repairs before being re-fitted along with outer wheel arch panels. The rear panel and wings needed to be altered to keep the curvaceous lines flowing over the haunches. The brand new bonnet was trial fitted before being trimmed to the bulk head and its wings altered to fit the sills. Once the necessary sill end panel and brackets were attached, the boys could then focus on the final flourishes - fitting the bonnet locks, the door locks and trial fitting the chrome.

With one very excited customer the car is now ready for primer and painting in Metallic Flag Blue.

Moving in to October saw the removal of the boot floor, the lower quarter and the number plate panel for repairs before being re-fitted along with outer wheel arch panels. The rear panel and wings needed to be altered to keep the curvaceous lines flowing over the haunches. The brand new bonnet was trial fitted before being trimmed to the bulk head and its wings altered to fit the sills. Once the necessary sill end panel and brackets were attached, the boys could then focus on the final flourishes - fitting the bonnet locks, the door locks and trial fitting the chrome.

With one very excited customer the car is now ready for primer and painting in Metallic Flag Blue.

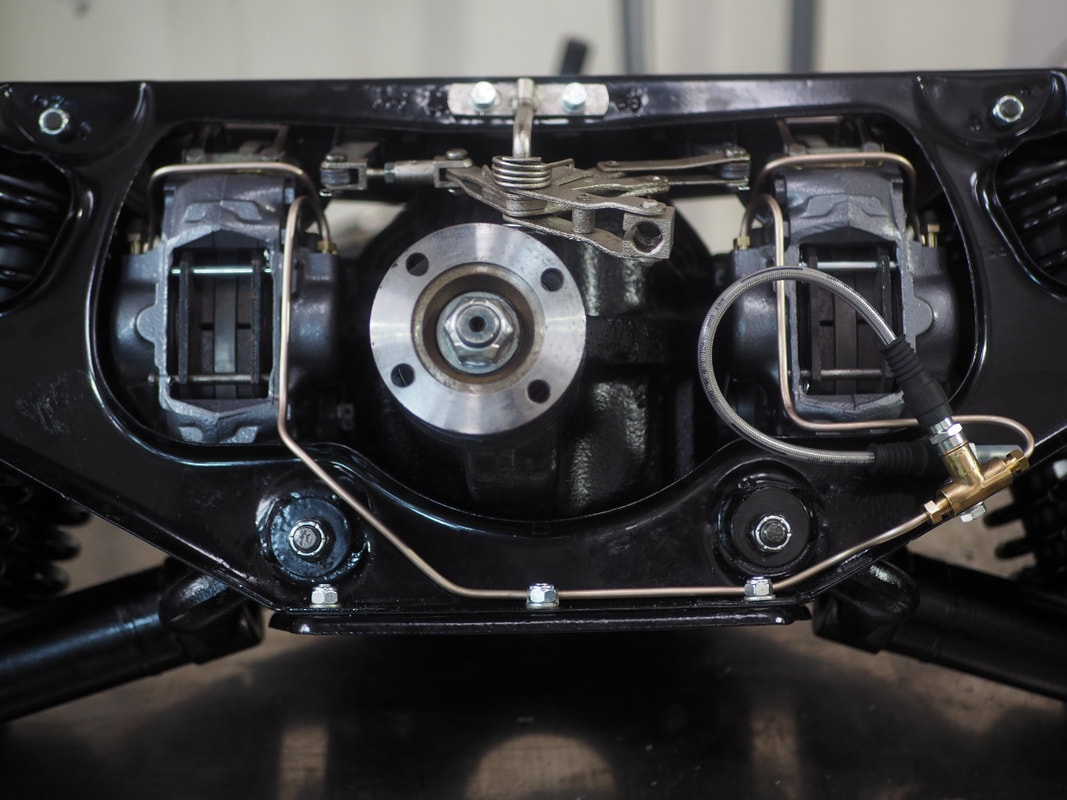

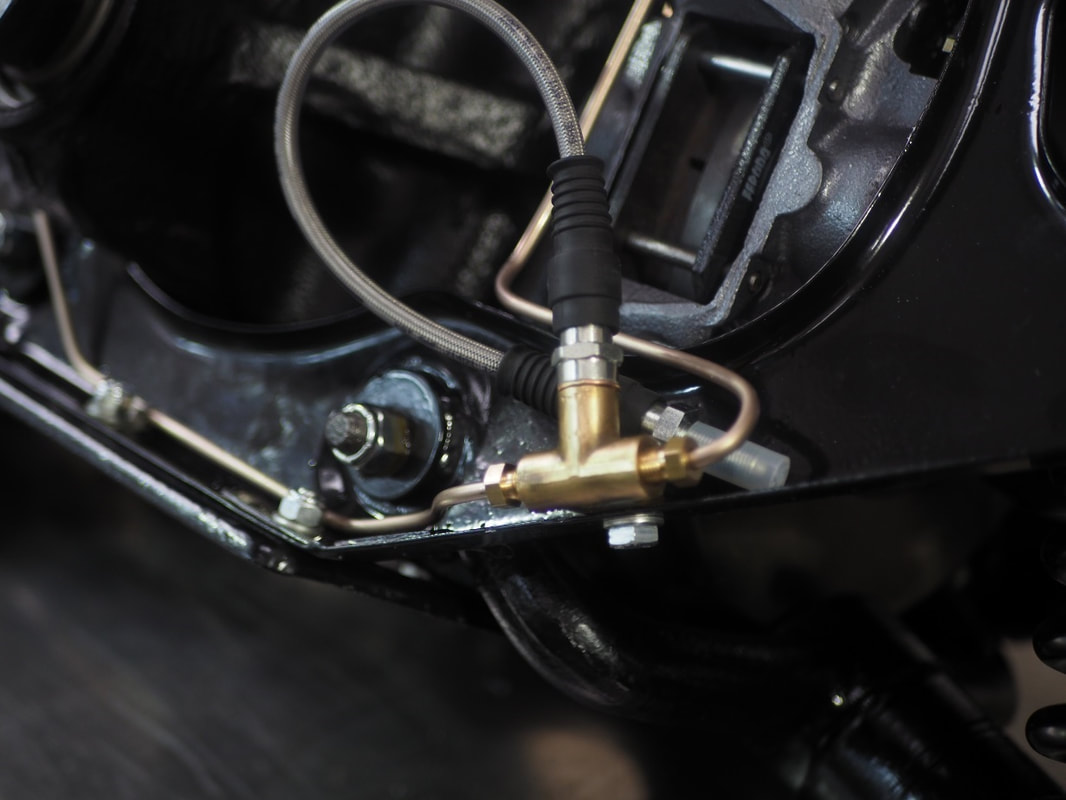

As we eagerly await the arrival of the Flag Blue shell from the paintshop next week, the boys have been rebuilding the Series 2 IRS system so that it can be married up to the body as soon as it is back in the restoration room. With a little over 5 months left to complete the car, milestone builds such as the rear axle rebuild are ticked off before its return to eliminate any valuable time loss.

Donning its original powrlok differential with a new ratio of 3:07, all of the salvageable parts were blasted before being either nickel plated or powder coated. Drive shaft UJ's were replaced with uprated whilst the springs and shock absorbers were thoroughly inspected prior to being repainted. The outer fulcrum, wheel and hub bearings were also replaced along with cunifer brake lines which were hand bent with precision.

Donning its original powrlok differential with a new ratio of 3:07, all of the salvageable parts were blasted before being either nickel plated or powder coated. Drive shaft UJ's were replaced with uprated whilst the springs and shock absorbers were thoroughly inspected prior to being repainted. The outer fulcrum, wheel and hub bearings were also replaced along with cunifer brake lines which were hand bent with precision.

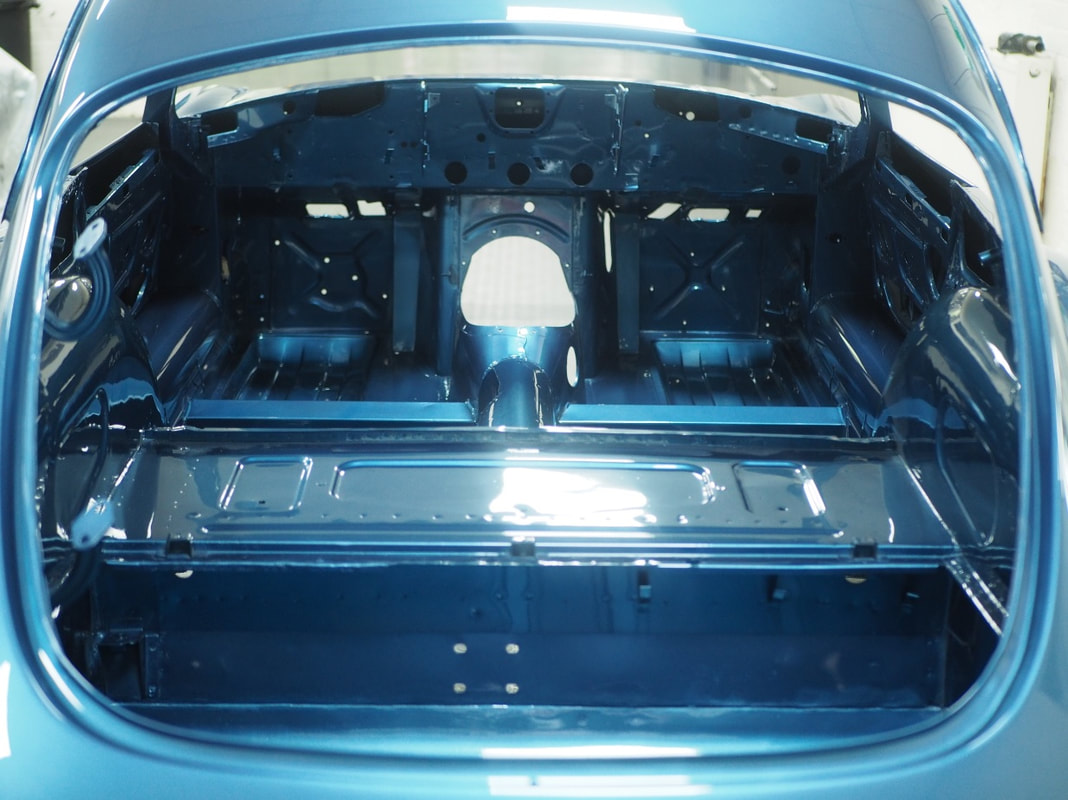

Completely transformed and enrobed in Metallic Flag Blue, the Series 2 shell and bonnet are now fresh out of paint and safely stored away in our clean and bright restoration room awaiting the next stages of the build. With the June 2021 deadline still calling out (Covid-19 allowing), the race is on to get the car ready hopefully in time for the E-Type 60th Anniversary celebrations.

Whilst waiting for the body to emerge from paint, the boys back at base have been working on the getting the IRS build completed to avoid eating in to the time once the shell was back. The trimmer is also lined up to install the Beige headlining kit and to begin the Biscuit interior trim. The customer is already thrilled with how the paint looks and is eagerly awaiting to see it against the warm creamy interior tones.

Whilst waiting for the body to emerge from paint, the boys back at base have been working on the getting the IRS build completed to avoid eating in to the time once the shell was back. The trimmer is also lined up to install the Beige headlining kit and to begin the Biscuit interior trim. The customer is already thrilled with how the paint looks and is eagerly awaiting to see it against the warm creamy interior tones.

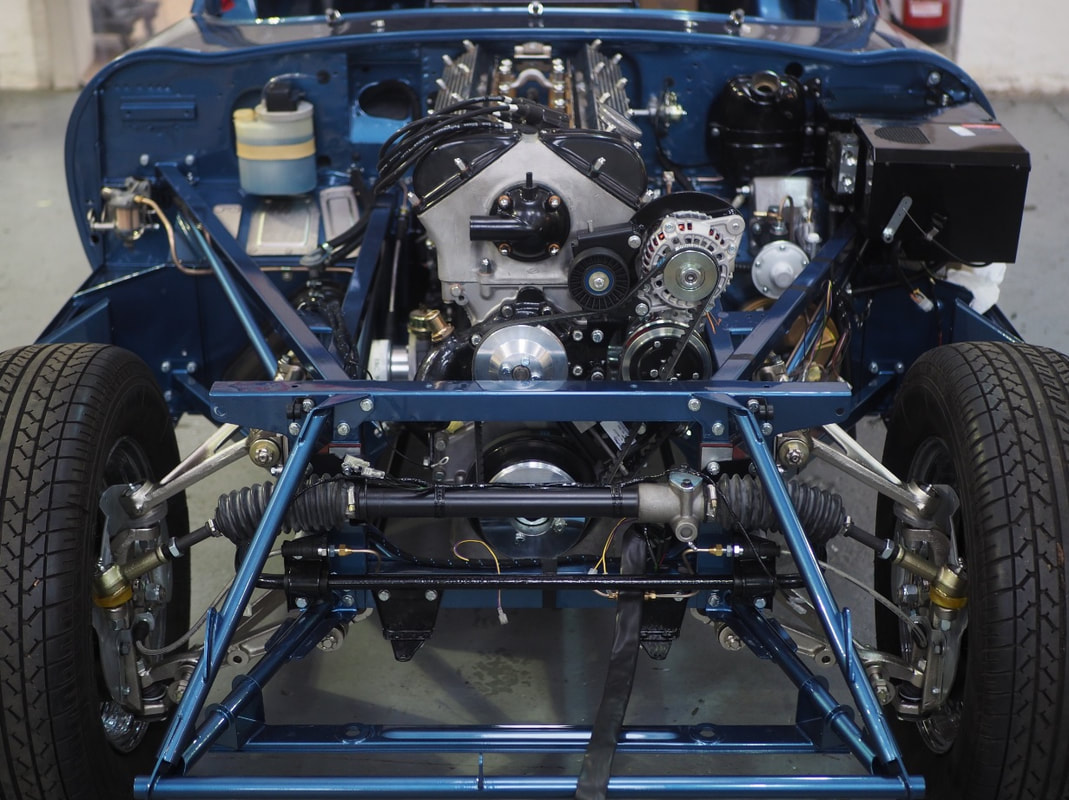

Wasting no time getting started, the past couple of months Murray has shut himself away in the restoration room project managing the initial stages of the build including sound deadening the cabin, laying out wiring looms, and the build up of the front and rear suspension. Whilst all the fuel lines were laid in, focus was also on the bell housing and gearbox with the target of getting the 4.2 engine in ASAP. Prior to this monumental moment though, all brake lines were fitted and the pedal box was stripped, inspected before being rebuilt with its salvageable or necessary replacement parts. Once we had reached the stage where the engine bay was ready to welcome the engine, the trimmer arrived to install the soft headlining.

Reunited with its infamous 4.2 engine, and completely overhauled original gearbox, the E-Type was starting to reveal its true beauty with another milestone achieved on the project. With the majority of the wiring running through the car, Murray's next mission was to install the fresh air-conditioning system ready to cool the client down on those sticky Spanish days.

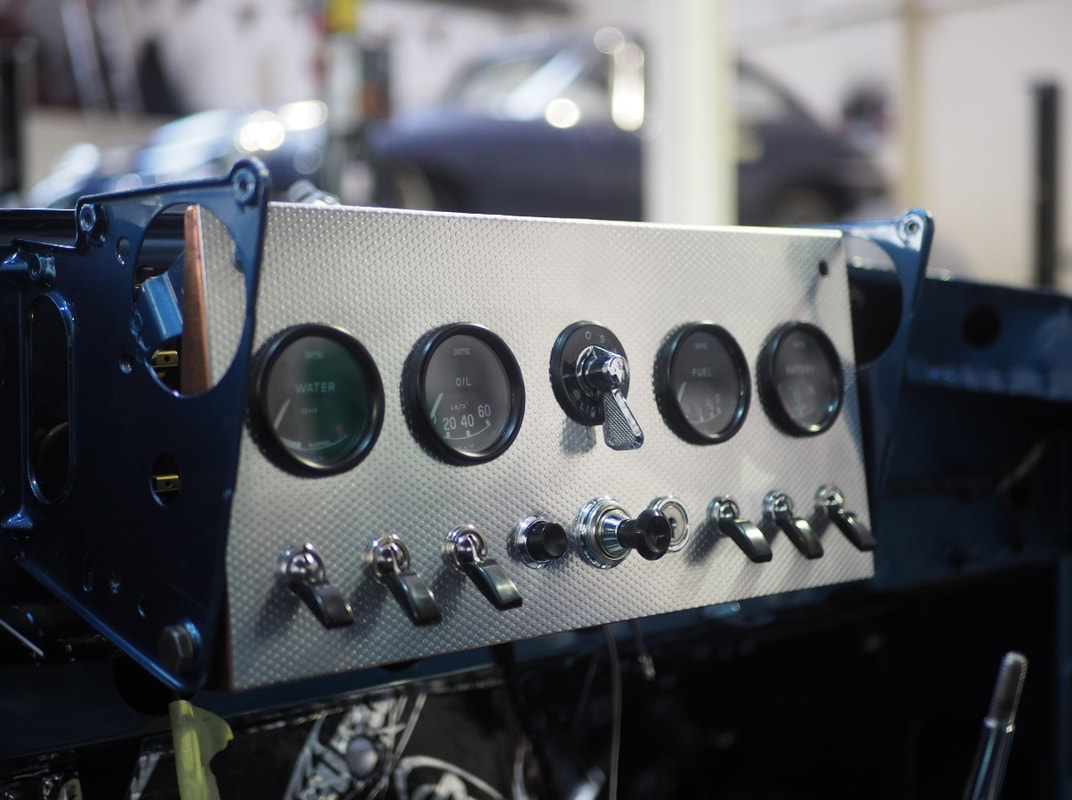

With Murray working tirelessly on the majority of the build, the rest of the team were handling all of the unseen but equally important tasks that really make the car. Barrie had been spending hours putting the bespoke aluminium centre dash together as per the request of the client. His brief was for the car to be predominantly a Series 2 but with early Series 1 elements and the decision was made to house the instrument gauges in dotted aluminium. At this stage we were almost ready to welcome back the trimmer again to start adding the Tan interior.

With Murray working tirelessly on the majority of the build, the rest of the team were handling all of the unseen but equally important tasks that really make the car. Barrie had been spending hours putting the bespoke aluminium centre dash together as per the request of the client. His brief was for the car to be predominantly a Series 2 but with early Series 1 elements and the decision was made to house the instrument gauges in dotted aluminium. At this stage we were almost ready to welcome back the trimmer again to start adding the Tan interior.

With the Series 2's final destination being sunny Spain, the clients wishes were to enrobe the interior in Biscuit as a nod to the inevitable coastal drives the customer will be making with the car. At first we were concerned that this particular colour would mark easily and quickly but as we were working alongside the trimmer, the overall look of the car and the contrast with the Flag Blue outweighed those worries. Customers who have visited the workshop have loved this combination, and when it is parked up by the beach people will certainly flock!

Getting ever impatient to fit the defining details, Murray gave in to temptation and fitted the re-chromed rear bumper and its badges of honour to the rear hatch.

Getting ever impatient to fit the defining details, Murray gave in to temptation and fitted the re-chromed rear bumper and its badges of honour to the rear hatch.

Now with the formidable bonnet fitted, using a handful of days for minor adjustments, essential wiring and making sure we had acceptable clearances, the team were faced with weeks of unseen, detail works which would ultimately be the most noticeable once the Series 2 was complete. Once the necessary areas were treated for rust prevention and future weatherproofing, important elements were fitted including the customers own seatbelts and heritage-correct Green drop glass and windscreen. With the window glass in place the build up of the doors could begin.

Focus soon turned to the final flourishes to the interior once the team had signed off all the remaining external works which included fitting the Bell exhaust system as requested by the customer, bleeding the brakes, and the meticulous task of the gutter chromes. Our brief from the customer was to create a reliable grand tourer that could take on the modern roads of Spain, and with that in mind we created a bespoke dotted Aluminium centre dash with a built in 7" touchscreen Satnav system to assist with touring. Incorporating elements from earlier E-Type interiors, we created a unique environment for the client which boasts all of the correct instruments but with a clean, modern approach.

With the client handover within reach, and the inviting cockpit enrobed in buttery Biscuit trim, the time had come to fit the steering wheel and get some Hertfordshire miles under her bonnet. With every nut and bolt restoration we never let a car leave our care without a minimum of 100 miles on the clock. This gives us the opportunity to fully de-bug the car and iron out any issues so that when the keys are handed over to the customer, we are confident that we have built a stable and reliable GT.

Focus soon turned to the final flourishes to the interior once the team had signed off all the remaining external works which included fitting the Bell exhaust system as requested by the customer, bleeding the brakes, and the meticulous task of the gutter chromes. Our brief from the customer was to create a reliable grand tourer that could take on the modern roads of Spain, and with that in mind we created a bespoke dotted Aluminium centre dash with a built in 7" touchscreen Satnav system to assist with touring. Incorporating elements from earlier E-Type interiors, we created a unique environment for the client which boasts all of the correct instruments but with a clean, modern approach.

With the client handover within reach, and the inviting cockpit enrobed in buttery Biscuit trim, the time had come to fit the steering wheel and get some Hertfordshire miles under her bonnet. With every nut and bolt restoration we never let a car leave our care without a minimum of 100 miles on the clock. This gives us the opportunity to fully de-bug the car and iron out any issues so that when the keys are handed over to the customer, we are confident that we have built a stable and reliable GT.