6th March 2020

The main priority has been adding the final touches to the 1967 Series 1 OTS restoration which is being collected by the extremely lucky customer this coming Monday. With 196 Hertfordshire miles clocked on her, and a deep clean and detail even under the car, the boys are fully satisfied with how the car performs and are looking forward to handing over the keys. The level of finish and detail that the car has been built to is astonishing. Murray and Leon's tenacious approach towards attention to detail and neatness is evident all over and inside the car. Final testing this week has proven that she is a joy to drive and will give the customer many years of comfortable and civilised touring. We will be sad to see the old girl go but equally we want to see her cruising past the long shop windows of West London.

The main priority has been adding the final touches to the 1967 Series 1 OTS restoration which is being collected by the extremely lucky customer this coming Monday. With 196 Hertfordshire miles clocked on her, and a deep clean and detail even under the car, the boys are fully satisfied with how the car performs and are looking forward to handing over the keys. The level of finish and detail that the car has been built to is astonishing. Murray and Leon's tenacious approach towards attention to detail and neatness is evident all over and inside the car. Final testing this week has proven that she is a joy to drive and will give the customer many years of comfortable and civilised touring. We will be sad to see the old girl go but equally we want to see her cruising past the long shop windows of West London.

28th February 2020

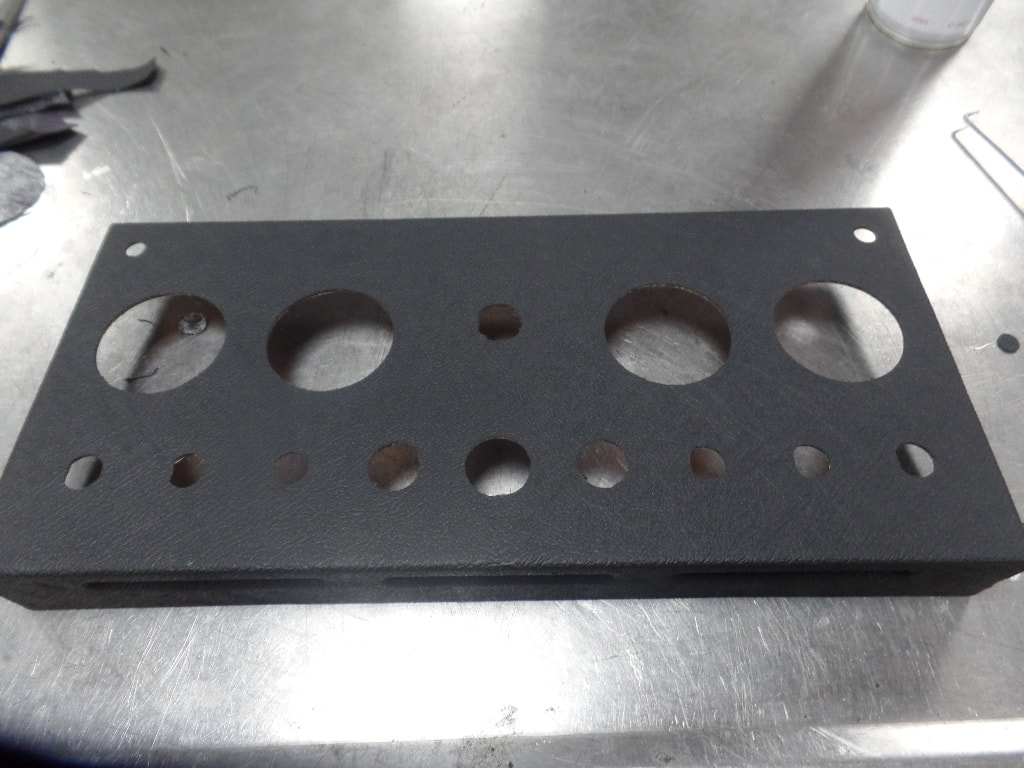

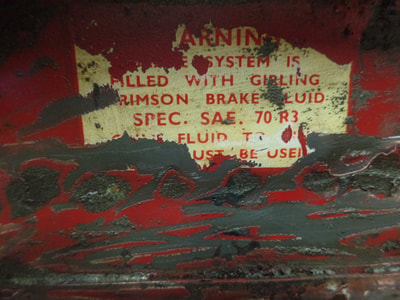

With just over a week to go until the collection of the ’67 Series 1 OTS restoration, Murray has been purely focusing on the finer details and finishing off the car ready for the big unveiling. His biggest achievement this week was fitting the bespoke seat runners to the upgraded sport seats to allow for smooth movement inside the car. Working with a local company, we produced CAD drawings and produced our ‘test’ set of runner adaptors. This means that we no longer have to use the original Jaguar runners (which were usually worn and had a lot of play in them). The result, an easy and gentle mechanism that we will now fit as standard to all of our cars. Final flourishes consisting of the ever-important Jaguar running-in windscreen sticker and the DOT5 Silicone brake fluid warning label have also been applied. We use DOT5 in all of our restorations as DOT4 can cause paint issues if leaks occur. As a matter of caution we will use these warning labels so that the system can be topped up with the correct fluid.

With just over a week to go until the collection of the ’67 Series 1 OTS restoration, Murray has been purely focusing on the finer details and finishing off the car ready for the big unveiling. His biggest achievement this week was fitting the bespoke seat runners to the upgraded sport seats to allow for smooth movement inside the car. Working with a local company, we produced CAD drawings and produced our ‘test’ set of runner adaptors. This means that we no longer have to use the original Jaguar runners (which were usually worn and had a lot of play in them). The result, an easy and gentle mechanism that we will now fit as standard to all of our cars. Final flourishes consisting of the ever-important Jaguar running-in windscreen sticker and the DOT5 Silicone brake fluid warning label have also been applied. We use DOT5 in all of our restorations as DOT4 can cause paint issues if leaks occur. As a matter of caution we will use these warning labels so that the system can be topped up with the correct fluid.

21st February 2020

With the March deadline fast approaching for the '67 Series 1 complete restoration (CB), a lot of little jobs have been completed this week starting with issues affecting the clutch. Leon discovered after a smooth road test that it was difficult to engage gears. Investigation of the push rod revealed that the ends (and clevis pin) had some wear. After welding and fettling, this problem was solved. Mudguard rubbers have been installed and the radiator stone shield mesh modified as it was too wide when it came to fitting it. In a bid to build a rattle free car, Leon also noticed that whilst out on road test the hood pivot mounts had the incorrect washers fitted (steel ones) so these were replaced with the correct thickness brass ones.

With the March deadline fast approaching for the '67 Series 1 complete restoration (CB), a lot of little jobs have been completed this week starting with issues affecting the clutch. Leon discovered after a smooth road test that it was difficult to engage gears. Investigation of the push rod revealed that the ends (and clevis pin) had some wear. After welding and fettling, this problem was solved. Mudguard rubbers have been installed and the radiator stone shield mesh modified as it was too wide when it came to fitting it. In a bid to build a rattle free car, Leon also noticed that whilst out on road test the hood pivot mounts had the incorrect washers fitted (steel ones) so these were replaced with the correct thickness brass ones.

14th February 2020

With the March deadline looming the focus this week was building up the bonnet. Following a successful 30 mile round-trip road test, both sugar scoops were installed to house the halogen H4 headlights, beading was meticulously measured out and attached before the defining chrome surrounds finished off the iconic bonnet details.

With the March deadline looming the focus this week was building up the bonnet. Following a successful 30 mile round-trip road test, both sugar scoops were installed to house the halogen H4 headlights, beading was meticulously measured out and attached before the defining chrome surrounds finished off the iconic bonnet details.

7th February 2020

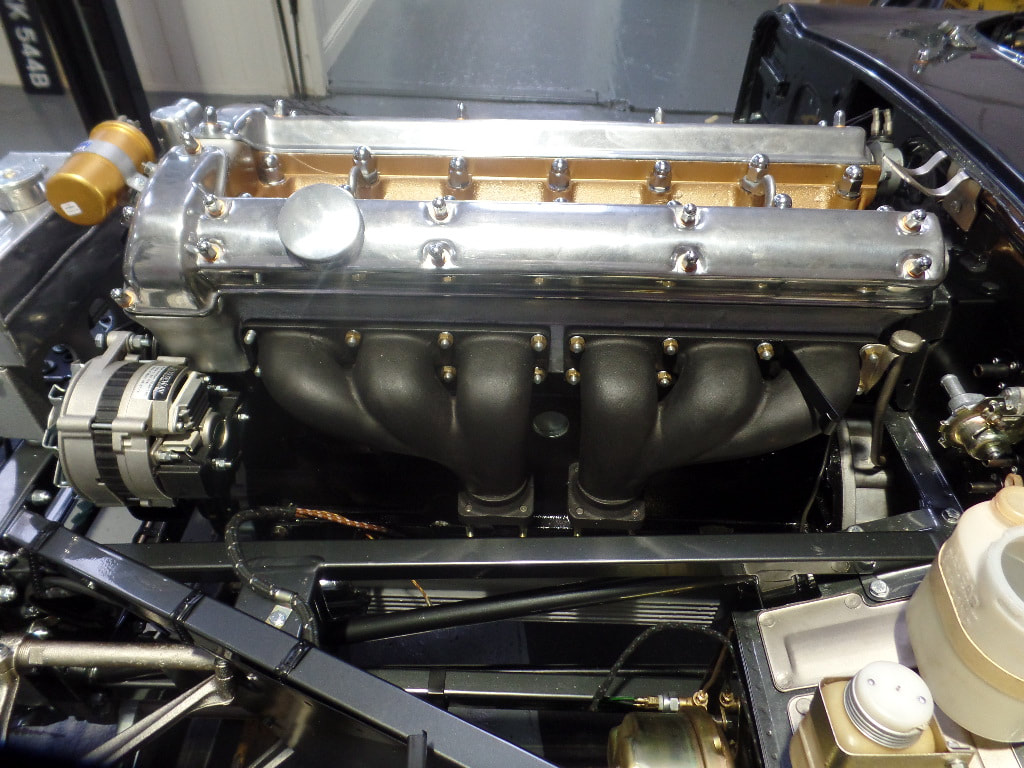

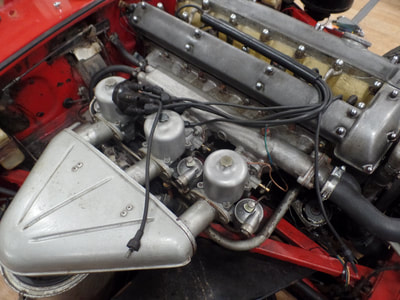

To end the busy week we are delighted to announce that the re-conditioned 4.2 engine, that belongs to the '67 Series 1 restoration, was fired up for the first time without any glitches! Always a magical moment in the workshop when we start the engine for the first time since being rebuilt and suddenly brings the car to life! Following the engine came a routine brake and clutch bleed, heat test, and all important timing adjustments. Leon and Murray have also been focusing on installing the period sound system as well as neatly fitting the speakers inside the footwells. Both seatbelts have also been fitted with the inertias concealed away in to the boot making for a tidier cockpit. Finally, the glovebox now houses a port for 2 USB connections and a cigar lighter. Following a recent successful visit from the customer we are now on the home stretch for our delivery date in March.

To end the busy week we are delighted to announce that the re-conditioned 4.2 engine, that belongs to the '67 Series 1 restoration, was fired up for the first time without any glitches! Always a magical moment in the workshop when we start the engine for the first time since being rebuilt and suddenly brings the car to life! Following the engine came a routine brake and clutch bleed, heat test, and all important timing adjustments. Leon and Murray have also been focusing on installing the period sound system as well as neatly fitting the speakers inside the footwells. Both seatbelts have also been fitted with the inertias concealed away in to the boot making for a tidier cockpit. Finally, the glovebox now houses a port for 2 USB connections and a cigar lighter. Following a recent successful visit from the customer we are now on the home stretch for our delivery date in March.

24th January 2020

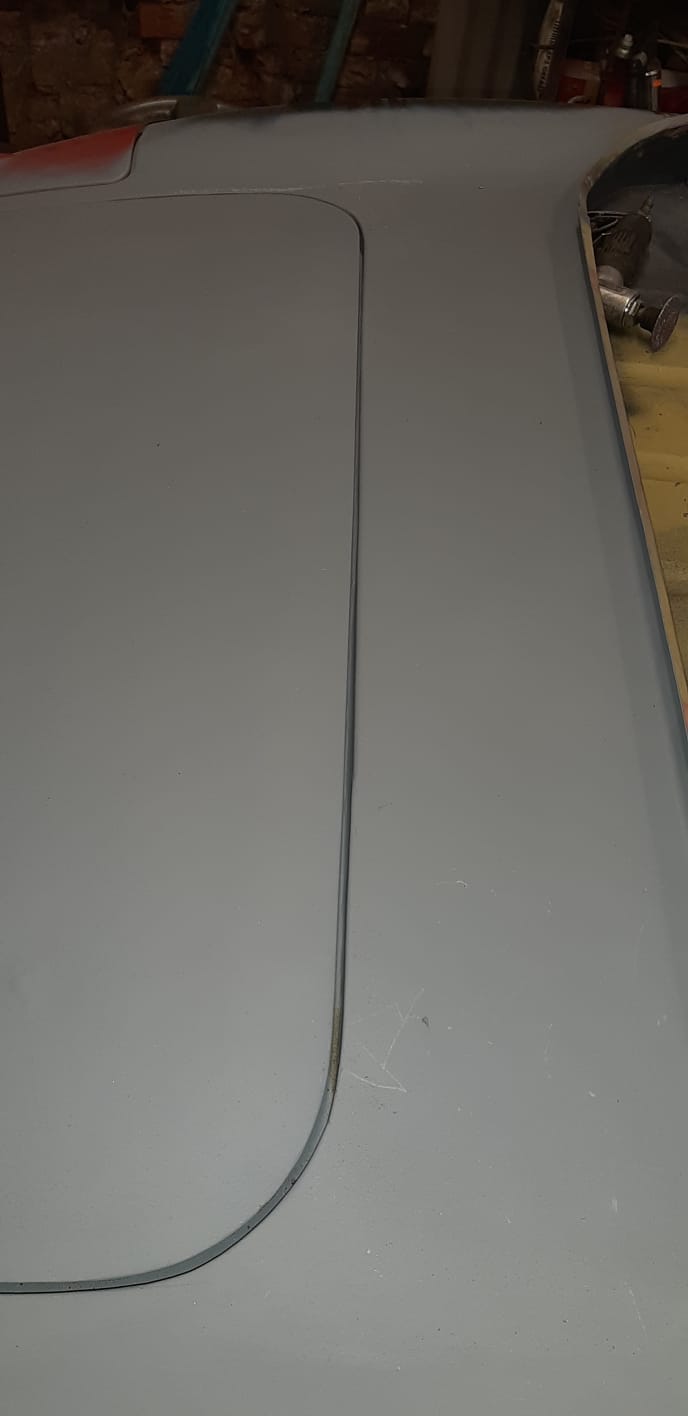

Following weeks of under the bonnet work and finishing off the necessary trim panels, we safely received the '67 Series 1 restoration back in to the workshop after having the black mohair canvas hood fitted and the results are superb. As with many E-Types the hood frames tend to need some extensive work prior to getting the perfect fit and this one was no exception. We are especially pleased with how the top of the windows evenly meet the cantrail rubbers when the doors shut. Ahead of the customer's visit next week we are so thrilled with how the car is progressing and believe they will share the same excitement as we do when they see the car.

Following weeks of under the bonnet work and finishing off the necessary trim panels, we safely received the '67 Series 1 restoration back in to the workshop after having the black mohair canvas hood fitted and the results are superb. As with many E-Types the hood frames tend to need some extensive work prior to getting the perfect fit and this one was no exception. We are especially pleased with how the top of the windows evenly meet the cantrail rubbers when the doors shut. Ahead of the customer's visit next week we are so thrilled with how the car is progressing and believe they will share the same excitement as we do when they see the car.

22nd November 2019

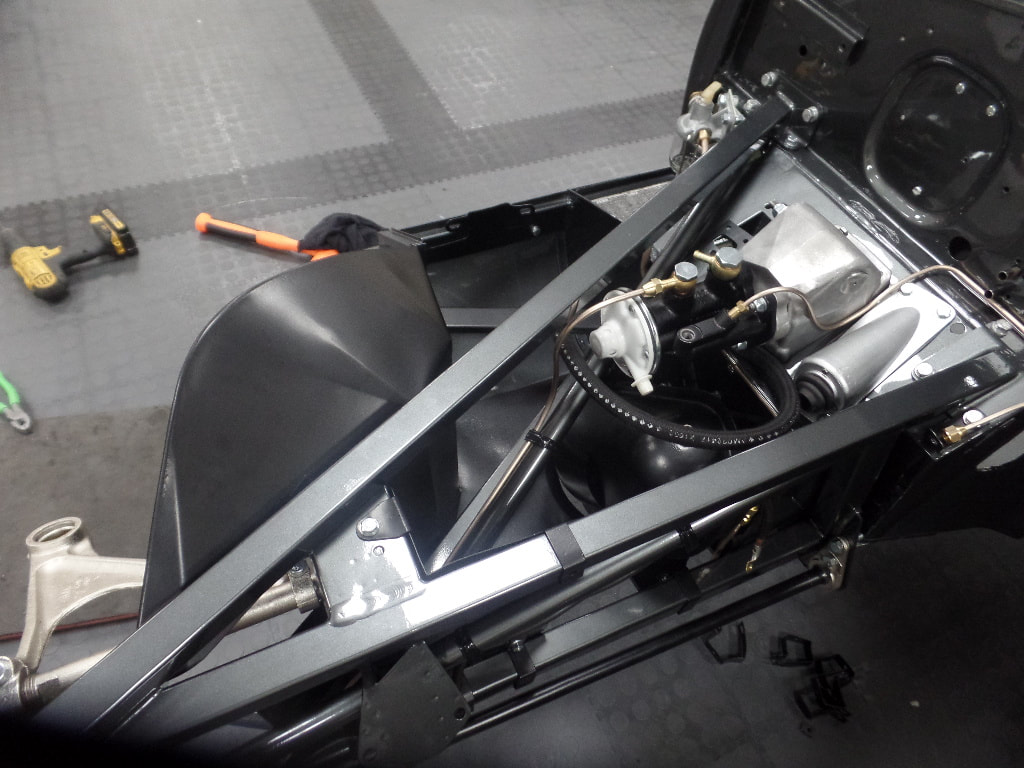

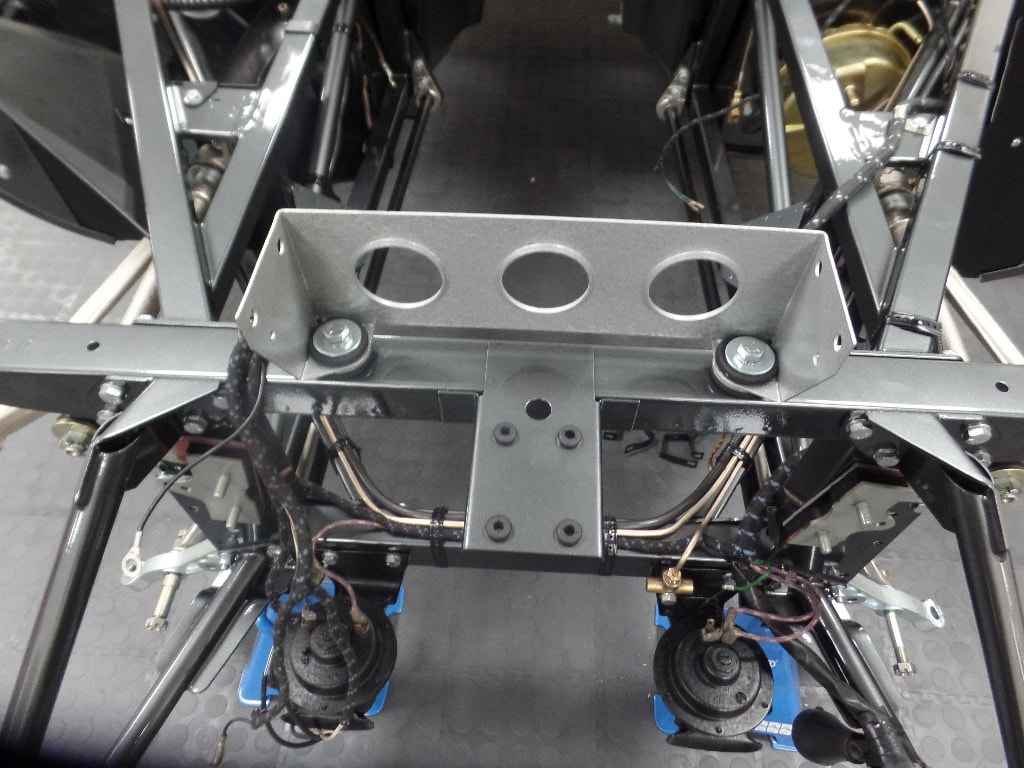

The reservoir bottles are now fitted and plumbed in.

The reservoir bottles are now fitted and plumbed in.

15th November 2019

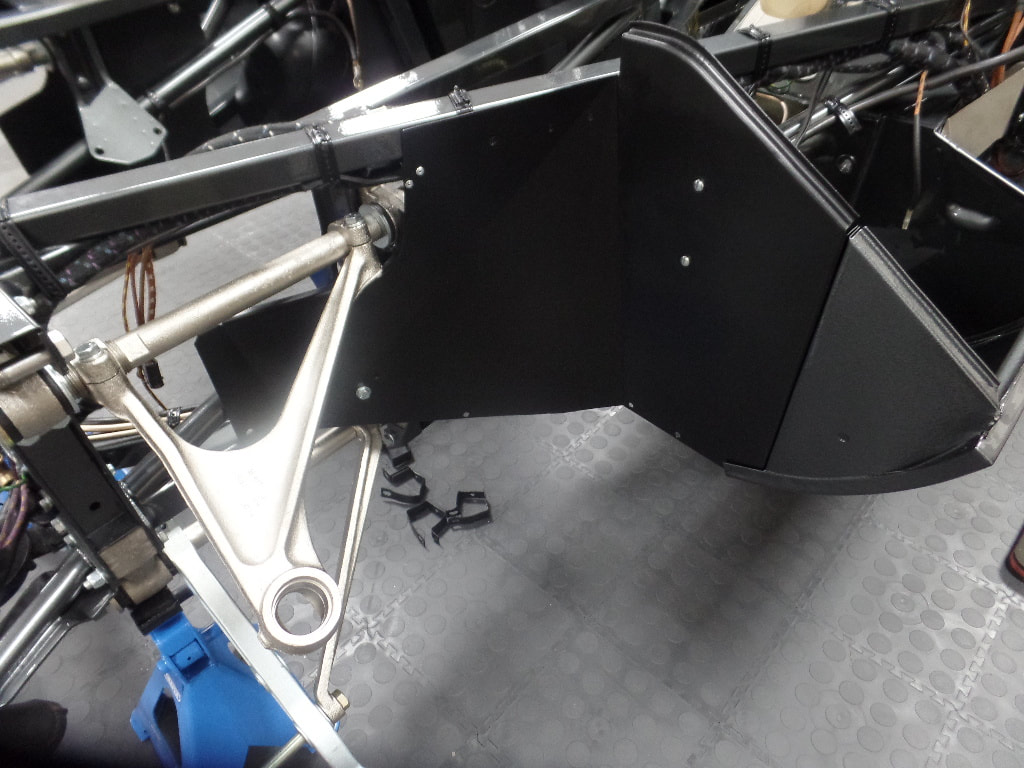

The car is just about ready for delivery to the hood trimmer. One job that we have to re-do is the set up of the front suspension - it is too low so we will have to re-check/set the torsion bars.

The car is just about ready for delivery to the hood trimmer. One job that we have to re-do is the set up of the front suspension - it is too low so we will have to re-check/set the torsion bars.

25th October 2019

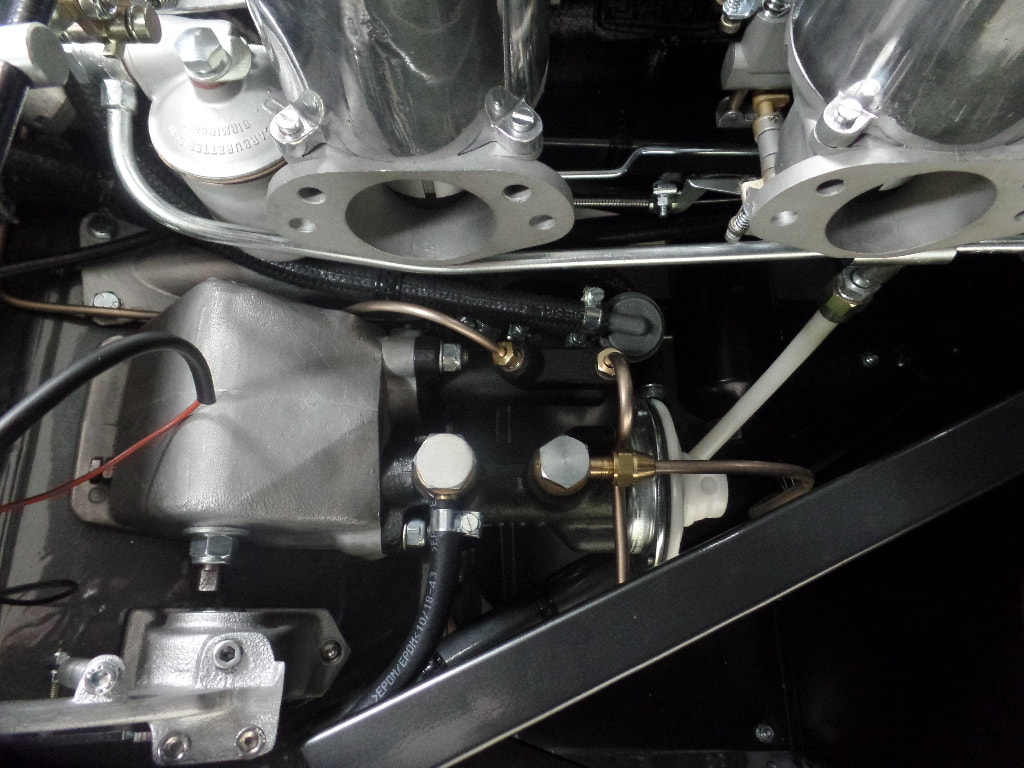

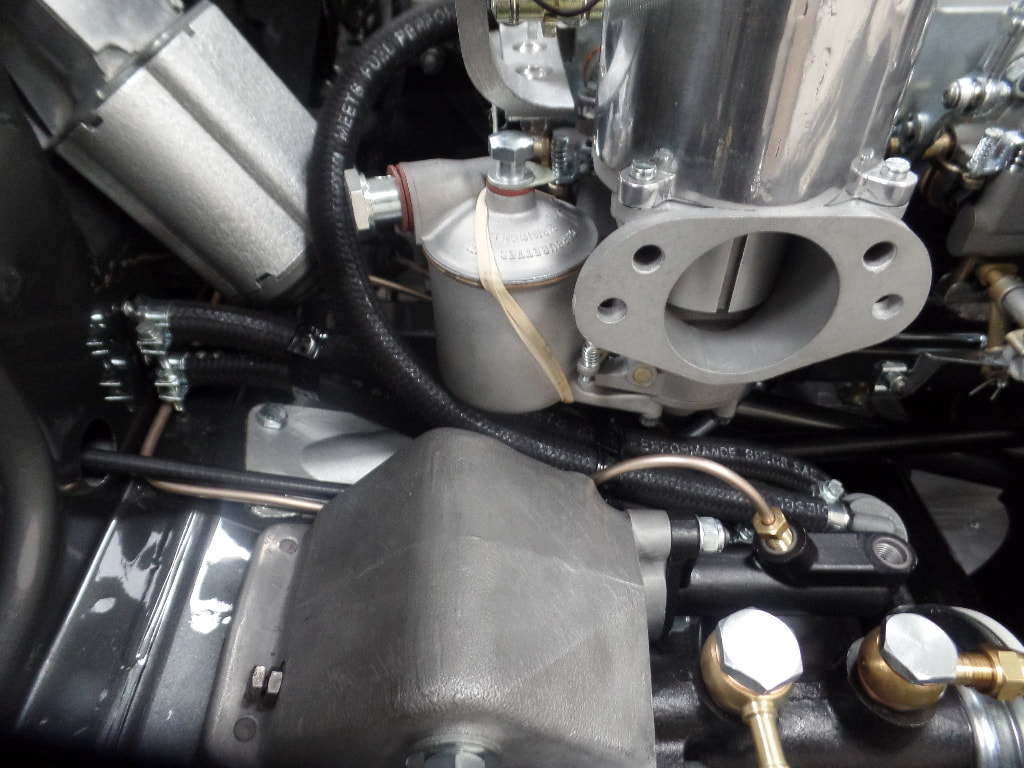

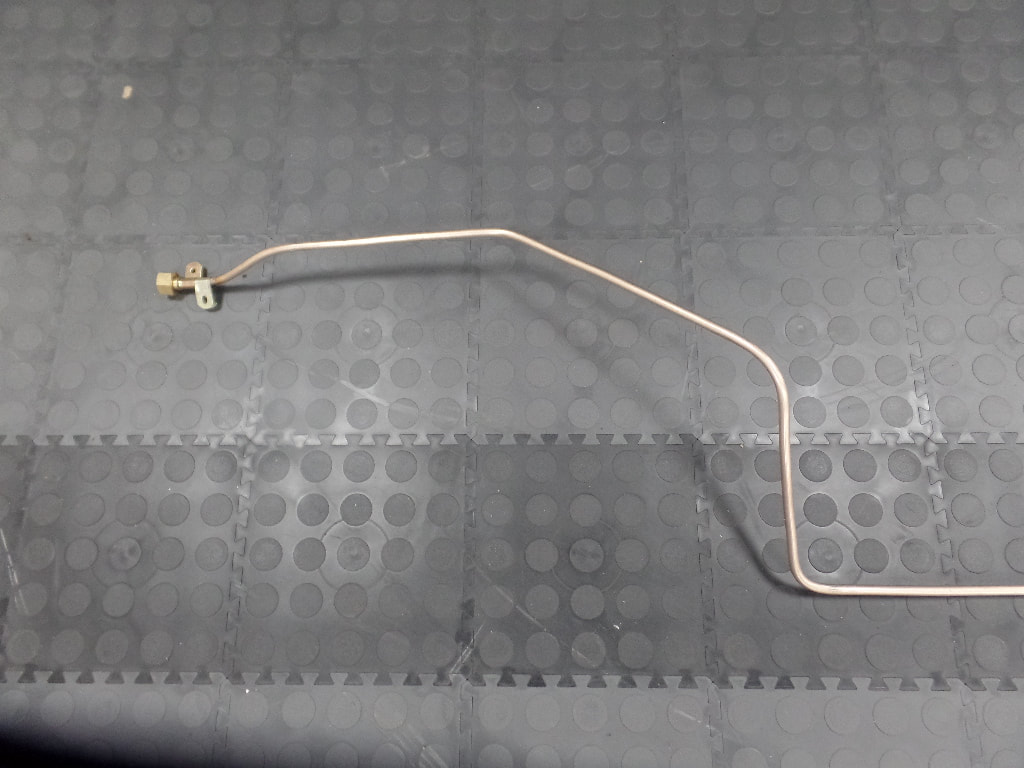

The carbs have been fitted and the boot has been prepared for the fuel tank fit. Vacuum pipes are in place.

The carbs have been fitted and the boot has been prepared for the fuel tank fit. Vacuum pipes are in place.

18th October 2019

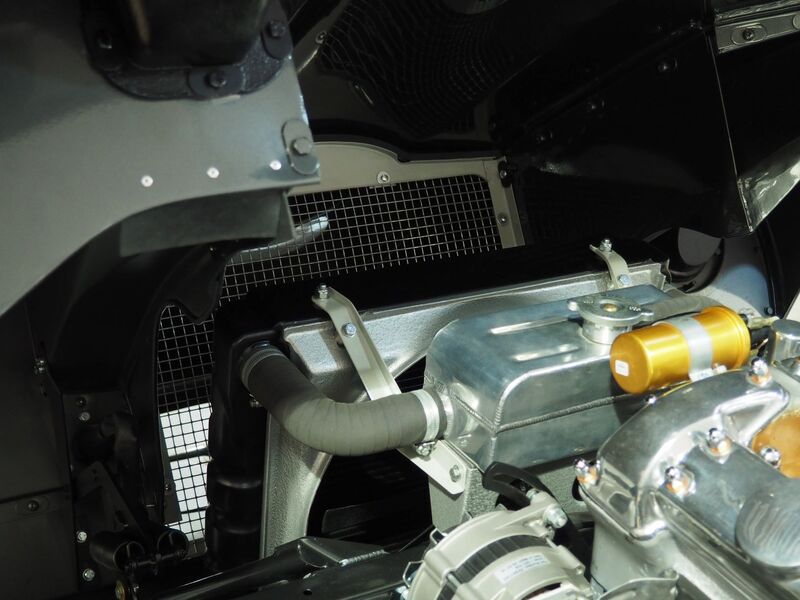

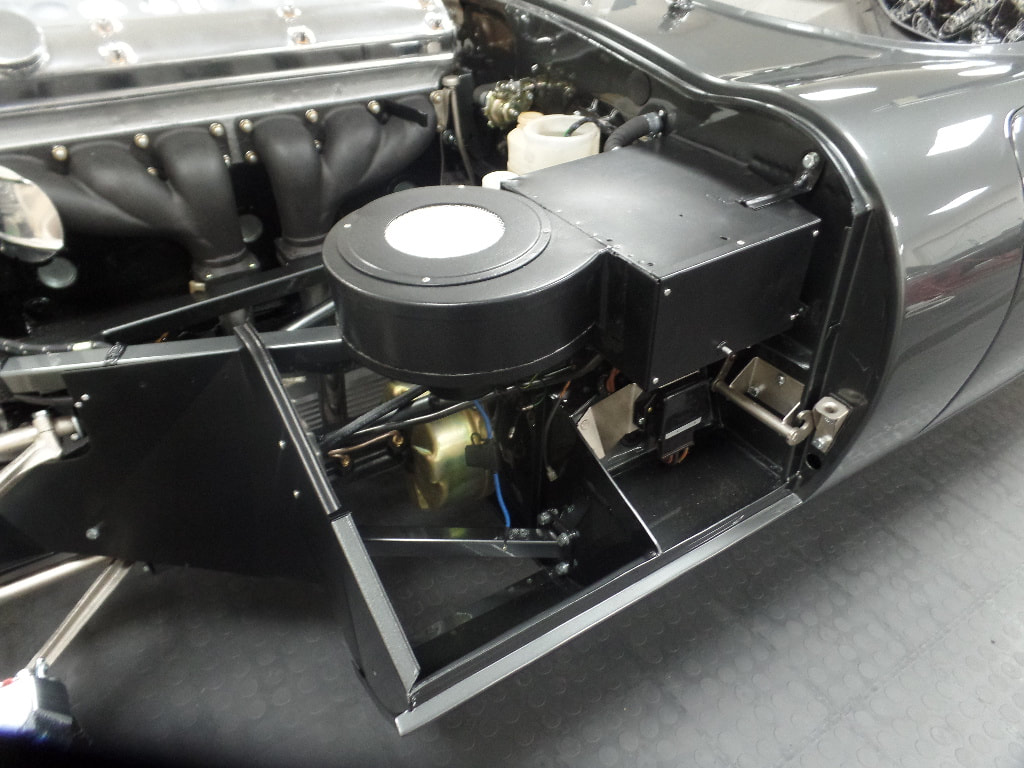

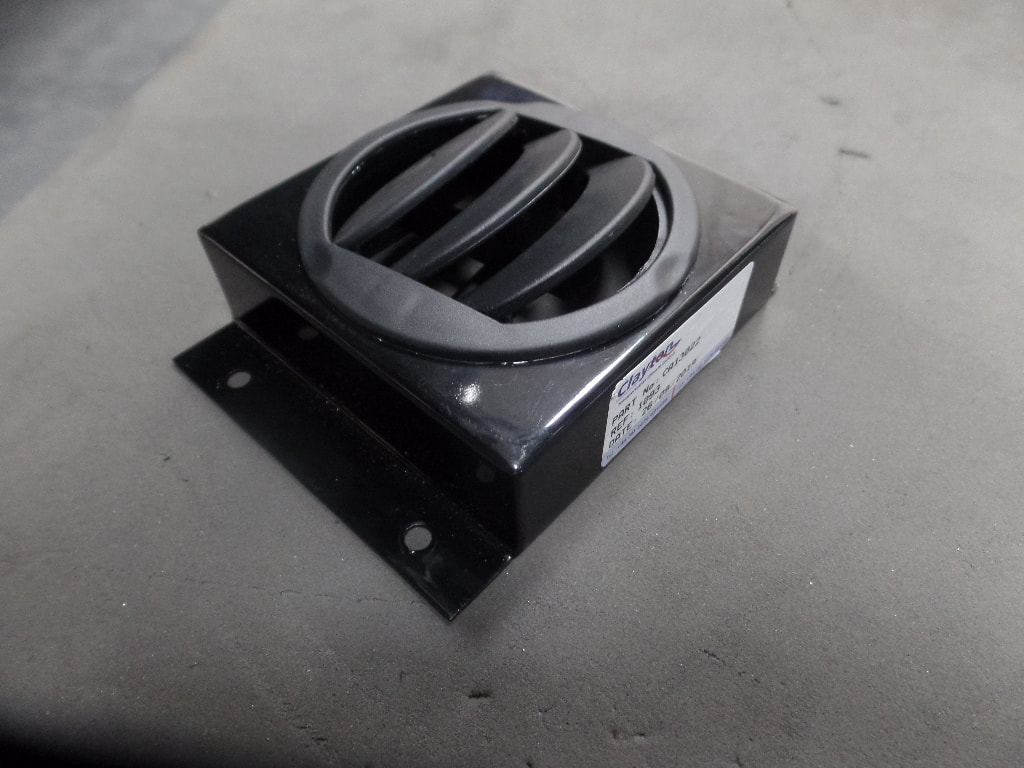

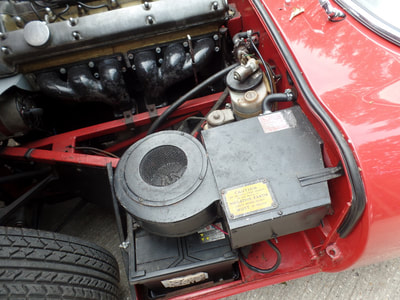

The build still moves on and the heater box with the upgraded fan, rear chrome, radiator etc have all been fitted. The underdash heater vents are in place and we had to repair the hood frame pivot mounts prior to going away for powder coating. We picked up the chrome plating today so that should start going on next week.

The build still moves on and the heater box with the upgraded fan, rear chrome, radiator etc have all been fitted. The underdash heater vents are in place and we had to repair the hood frame pivot mounts prior to going away for powder coating. We picked up the chrome plating today so that should start going on next week.

11th October 2019

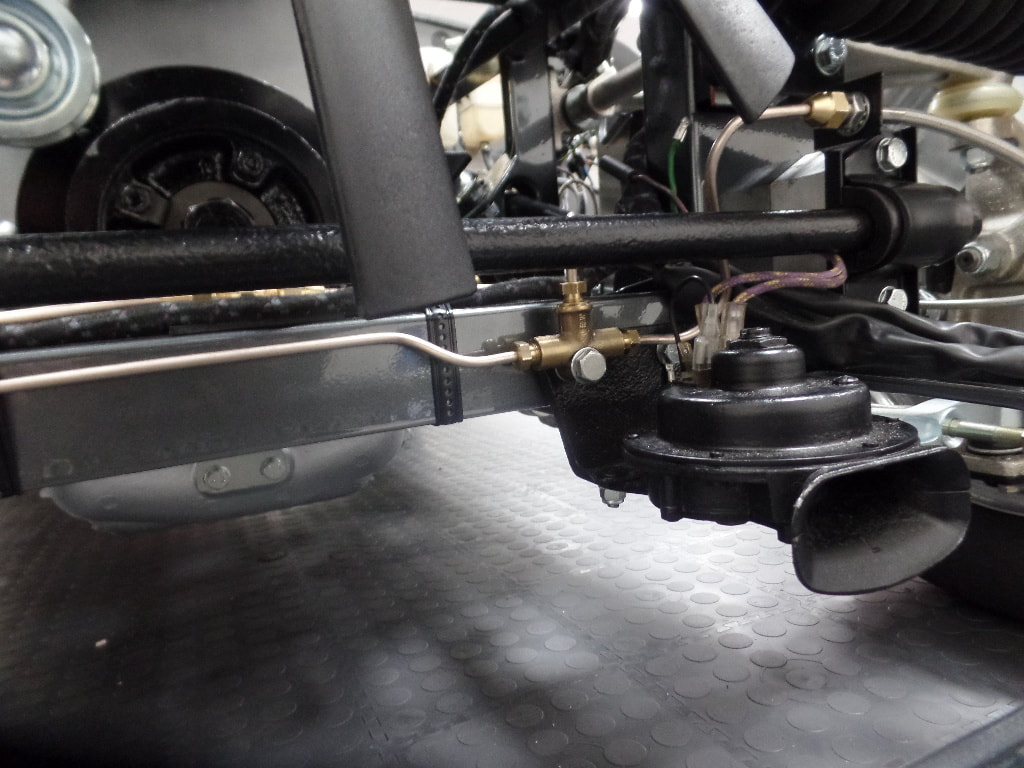

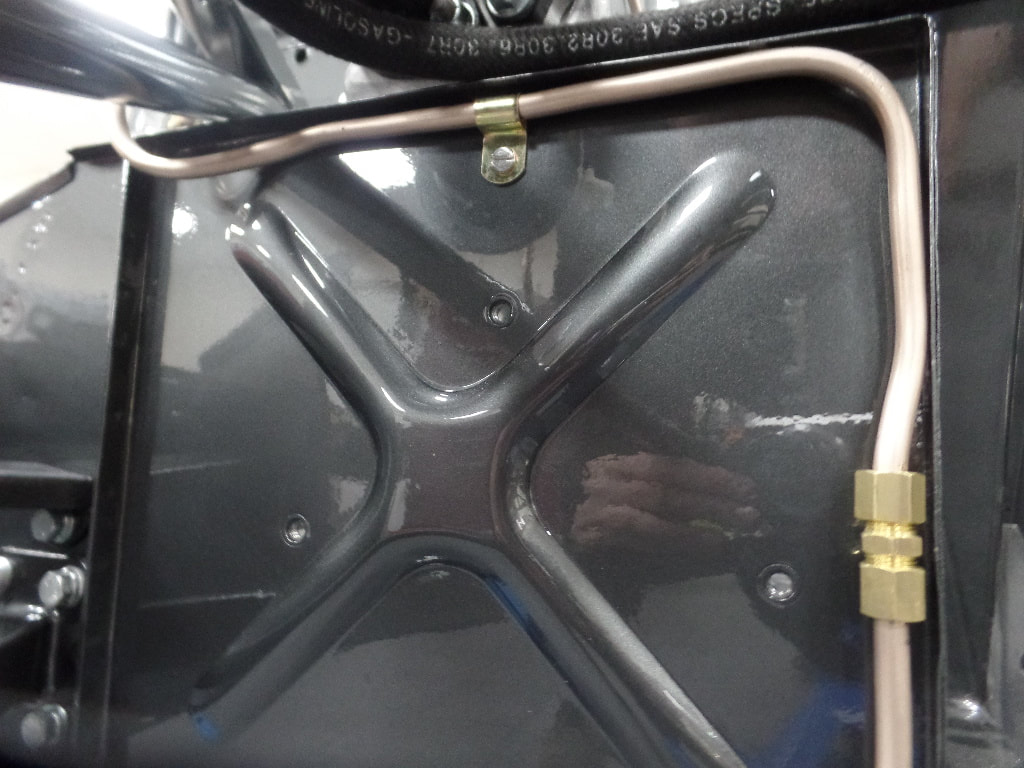

Lots more small jobs finished this week and the handbrake is back from rechroming, built up and fitted, seatbelt plaque rivetted in position and brake lines finalised.

Lots more small jobs finished this week and the handbrake is back from rechroming, built up and fitted, seatbelt plaque rivetted in position and brake lines finalised.

27th September 2019

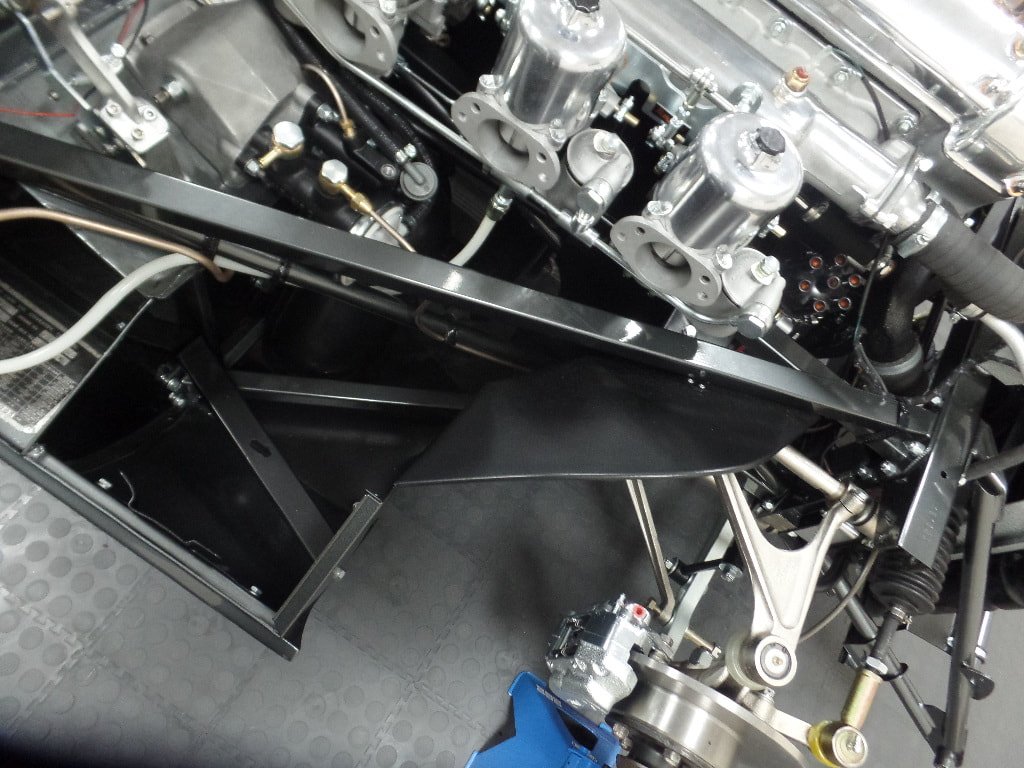

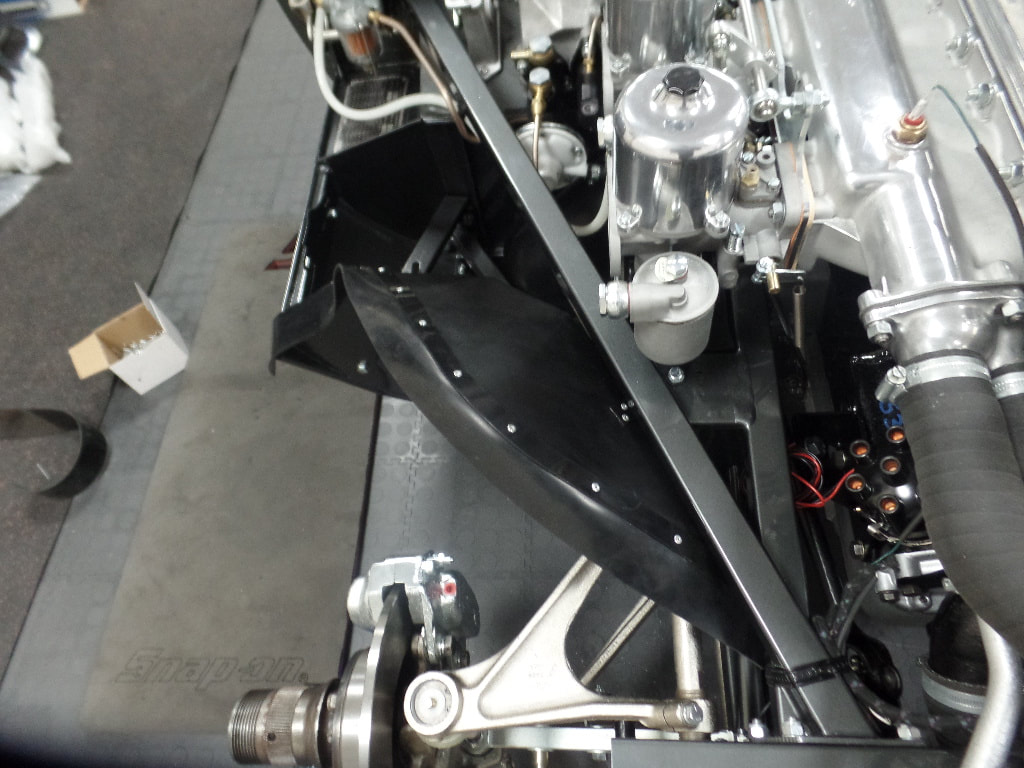

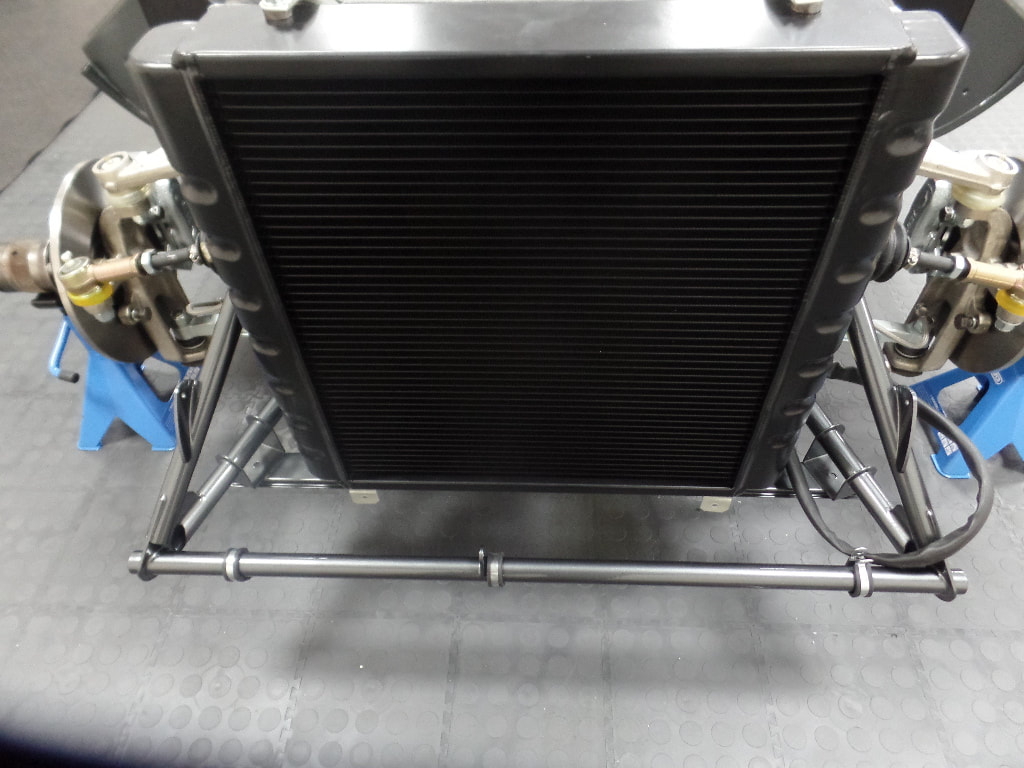

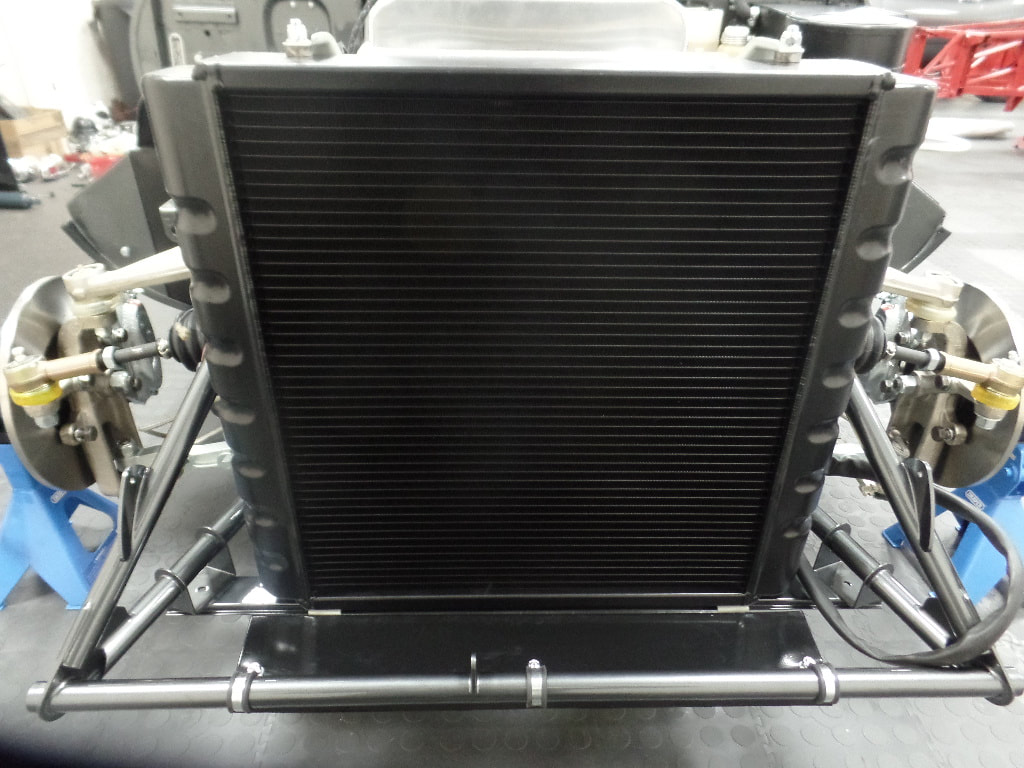

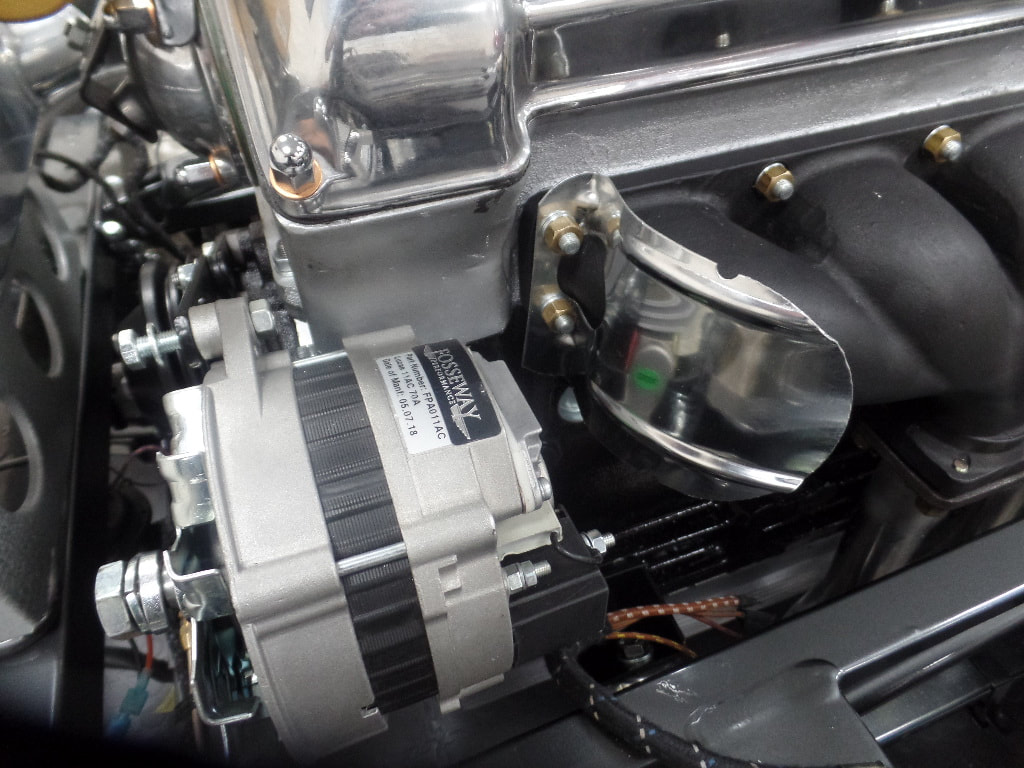

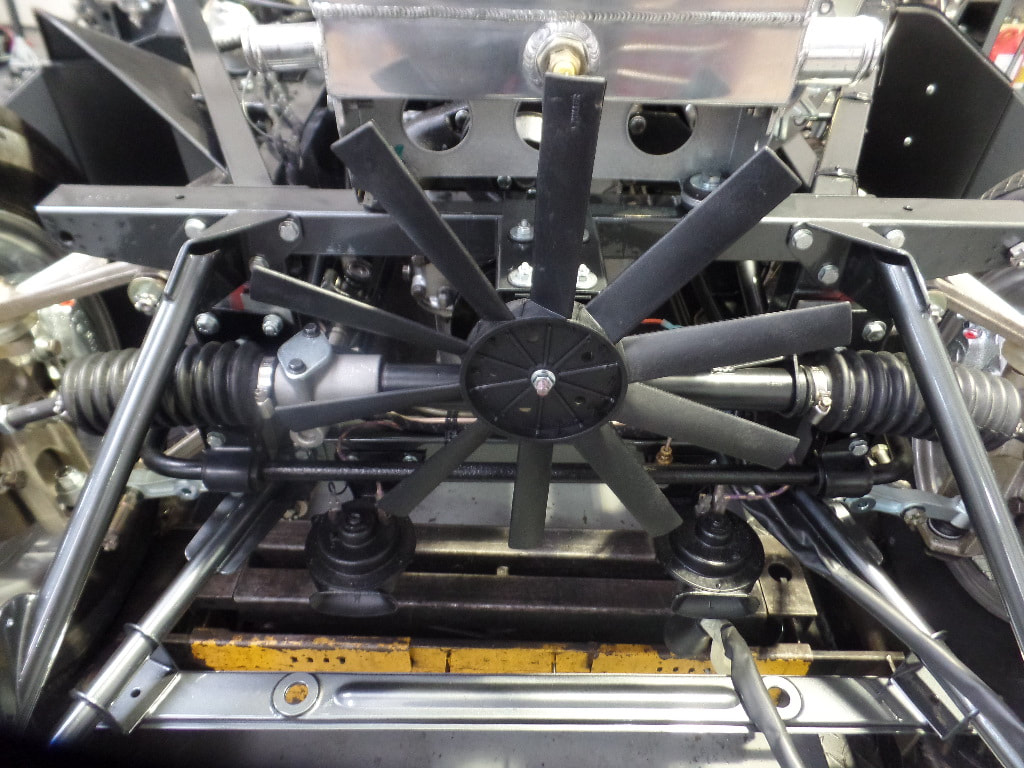

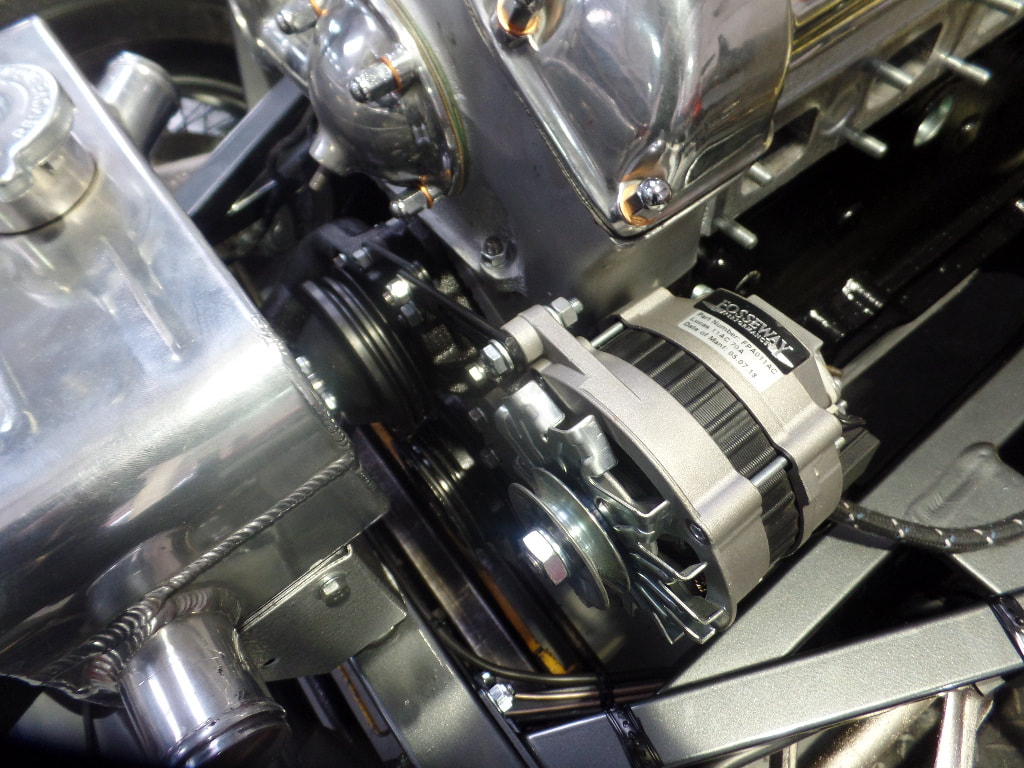

The under bonnet is really coming together now. The engine is now back where it belongs and we have the heatshields, alternator, cooling fan and lots of other small parts in place. Just waiting for the new aluminium radiator to arrive so we can button up the front of the engine bay.

The under bonnet is really coming together now. The engine is now back where it belongs and we have the heatshields, alternator, cooling fan and lots of other small parts in place. Just waiting for the new aluminium radiator to arrive so we can button up the front of the engine bay.

20th September 2019

Main focus this week and we are planning on the engine going in at the end of next week (dependent on all the parts arriving for the gearbox build).

Main focus this week and we are planning on the engine going in at the end of next week (dependent on all the parts arriving for the gearbox build).

13th September 2019

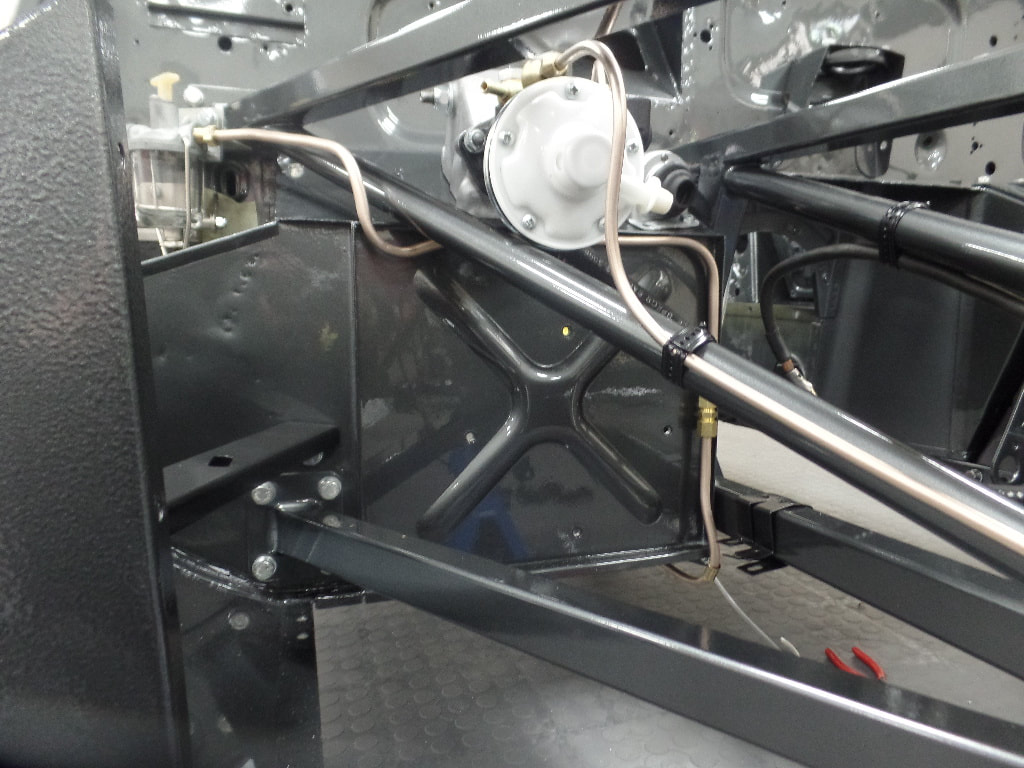

Lots of work finished this week. Engine bay coming along nicely, fuel line and back axle fitted. Engine should be fitted end of next week.

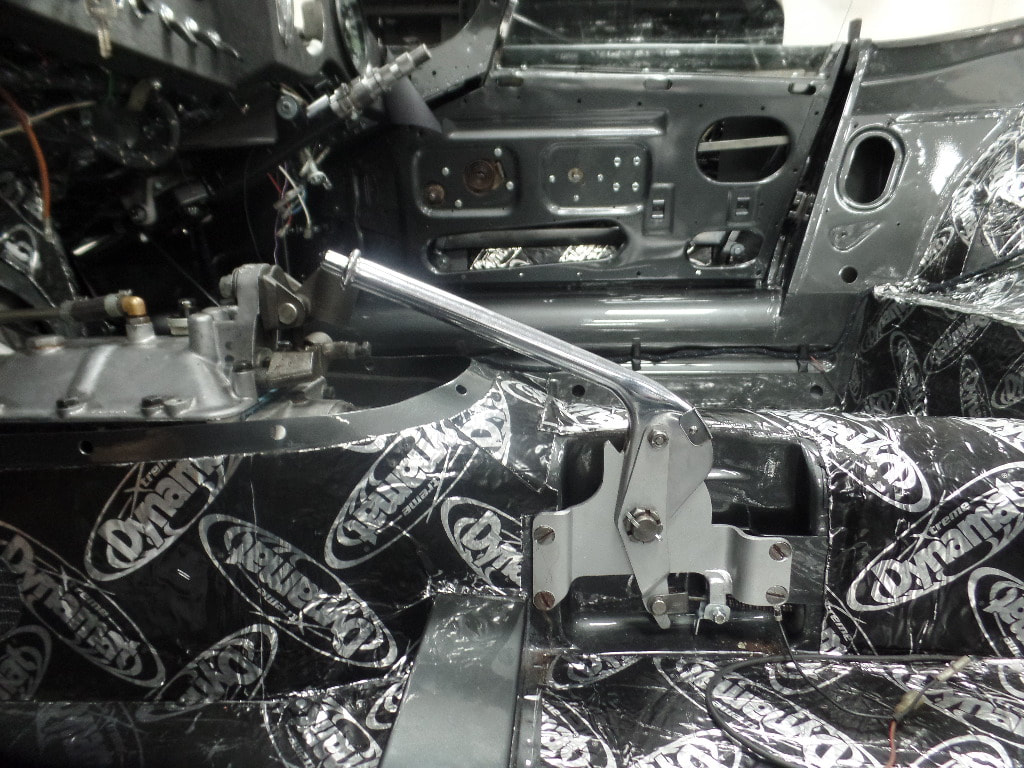

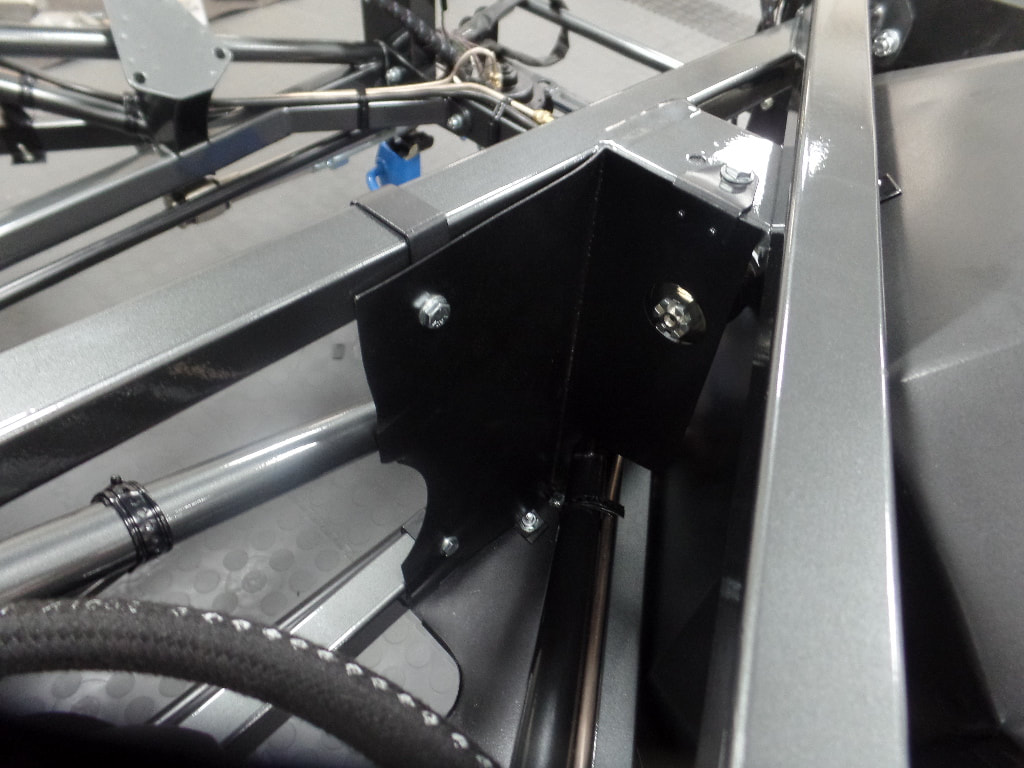

We are always looking for ways to improve our cars and we have fitted some sound deadening foam to the outside of the transmission tunnel in an attempt to mute the mechanical noise from the gearbox.

Lots of work finished this week. Engine bay coming along nicely, fuel line and back axle fitted. Engine should be fitted end of next week.

We are always looking for ways to improve our cars and we have fitted some sound deadening foam to the outside of the transmission tunnel in an attempt to mute the mechanical noise from the gearbox.

6th September 2019

All the wiring loom insulation is in place and the captive nuts have been tapped out.

All the wiring loom insulation is in place and the captive nuts have been tapped out.

30th August 2019

With the bonnet removed Murray has begun the Dynamat phase. Next week we will lay out the components to put together our parts lists.

With the bonnet removed Murray has begun the Dynamat phase. Next week we will lay out the components to put together our parts lists.

23rd August 2019

With the shell safely back in the workshop we can now start the build.

With the shell safely back in the workshop we can now start the build.

16th August 2019

The shell is finished in the paintshop and will be picked up next week.

The shell is finished in the paintshop and will be picked up next week.

9th August 2019

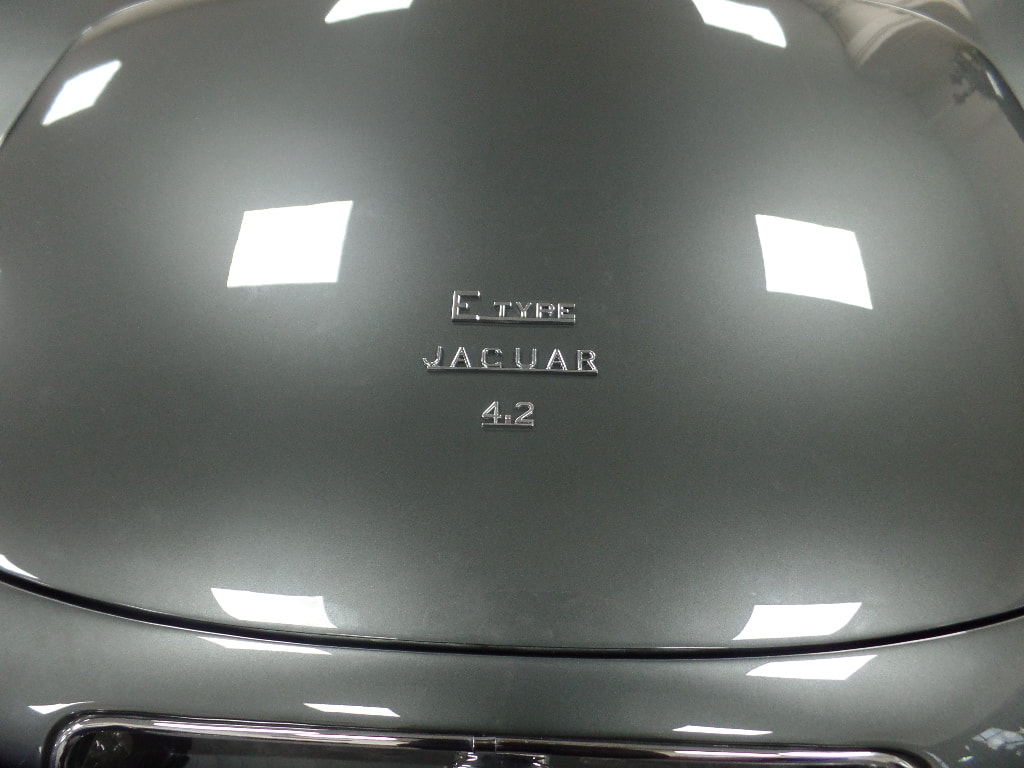

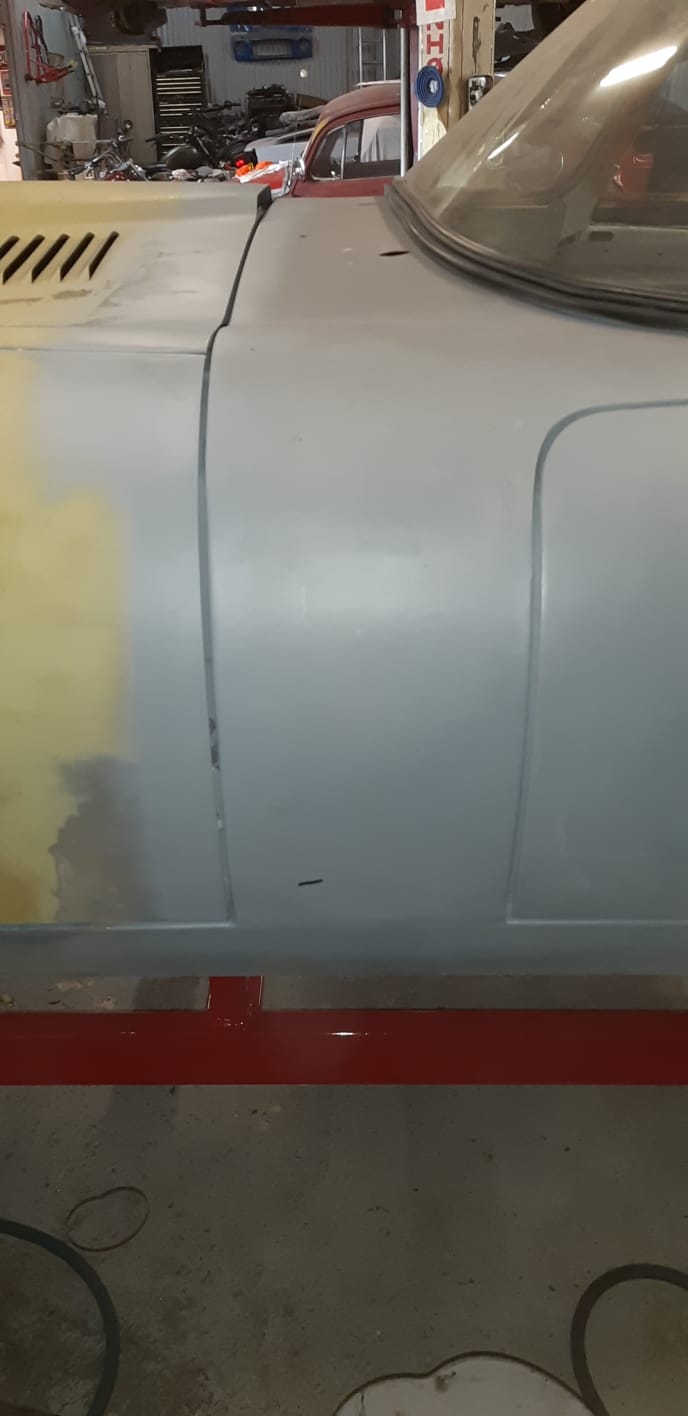

The car freshly painted but not yet polished. The Gunmetal Grey looks absolutely stunning.

The car freshly painted but not yet polished. The Gunmetal Grey looks absolutely stunning.

2nd August 2019

The team have been busy on the shell and the underneath and inside has been painted along with the frames and bulkhead.

The team have been busy on the shell and the underneath and inside has been painted along with the frames and bulkhead.

19th July 2019

The car now has the first coat of primer applied. Second coat next week and then paint.

The car now has the first coat of primer applied. Second coat next week and then paint.

12th July 2019

The boys been busy getting the shell ready for primer. Won't be long before we are in paint now.

The boys been busy getting the shell ready for primer. Won't be long before we are in paint now.

21st June 2019

The shell was delivered and taken straight over to the paintshop. The handbrake ratchet was stripped, checked and painted while the rest of the mechanism went away for plating.

The shell was delivered and taken straight over to the paintshop. The handbrake ratchet was stripped, checked and painted while the rest of the mechanism went away for plating.

14th June 2019

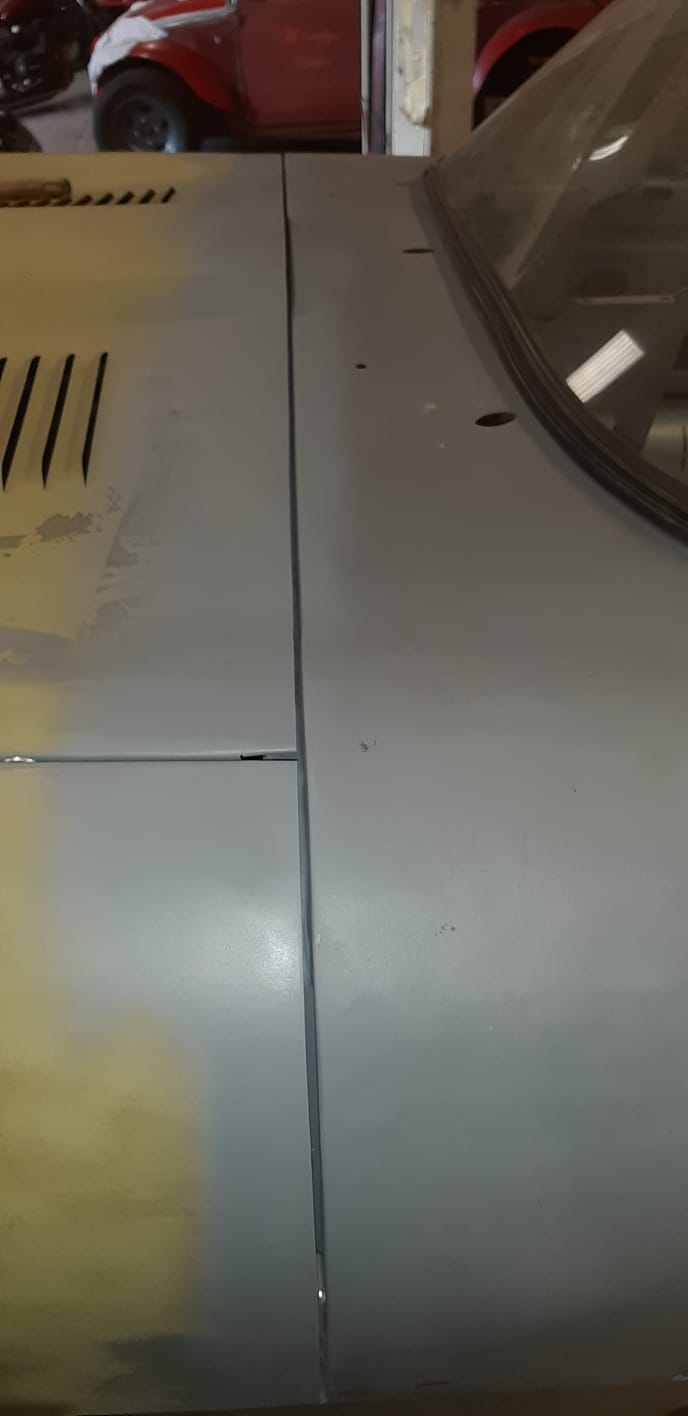

All the metal work is complete and the dry build finished. Looks absolutely stunning. Meeting with the paint shop guys next week to finalise a few things.

All the metal work is complete and the dry build finished. Looks absolutely stunning. Meeting with the paint shop guys next week to finalise a few things.

31st May 2019

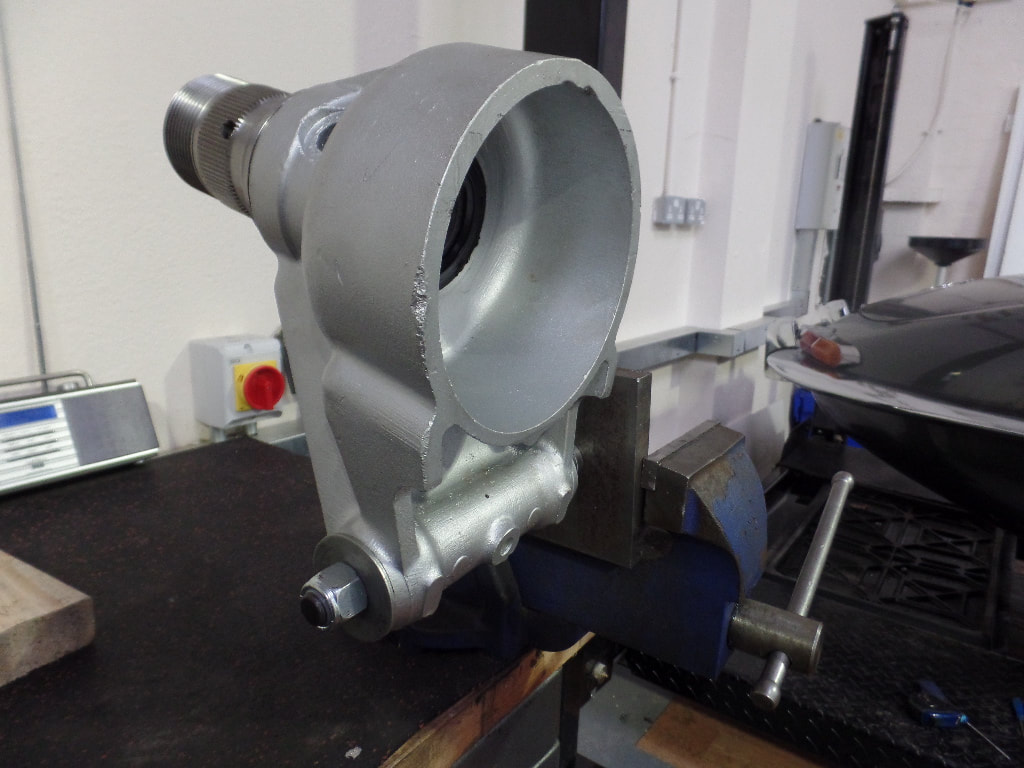

Steering column. We had to repair the fracture crack prior to powder coating.

Steering column. We had to repair the fracture crack prior to powder coating.

24th May 2019

Our new trolley is built and the shell sits on it awaiting the fitting of the bonnet.

Our new trolley is built and the shell sits on it awaiting the fitting of the bonnet.

3rd May 2019

The stripping down of components continues and the steering column revealed a nasty crack. This will be welded prior to blasting and powder coating. Meanwhile the bodyshell is now finished while we await 2 components in order to get the bonnet built. All the chrome has been trial fitted and we should be ready for paint very soon.

The stripping down of components continues and the steering column revealed a nasty crack. This will be welded prior to blasting and powder coating. Meanwhile the bodyshell is now finished while we await 2 components in order to get the bonnet built. All the chrome has been trial fitted and we should be ready for paint very soon.

26th April 2019

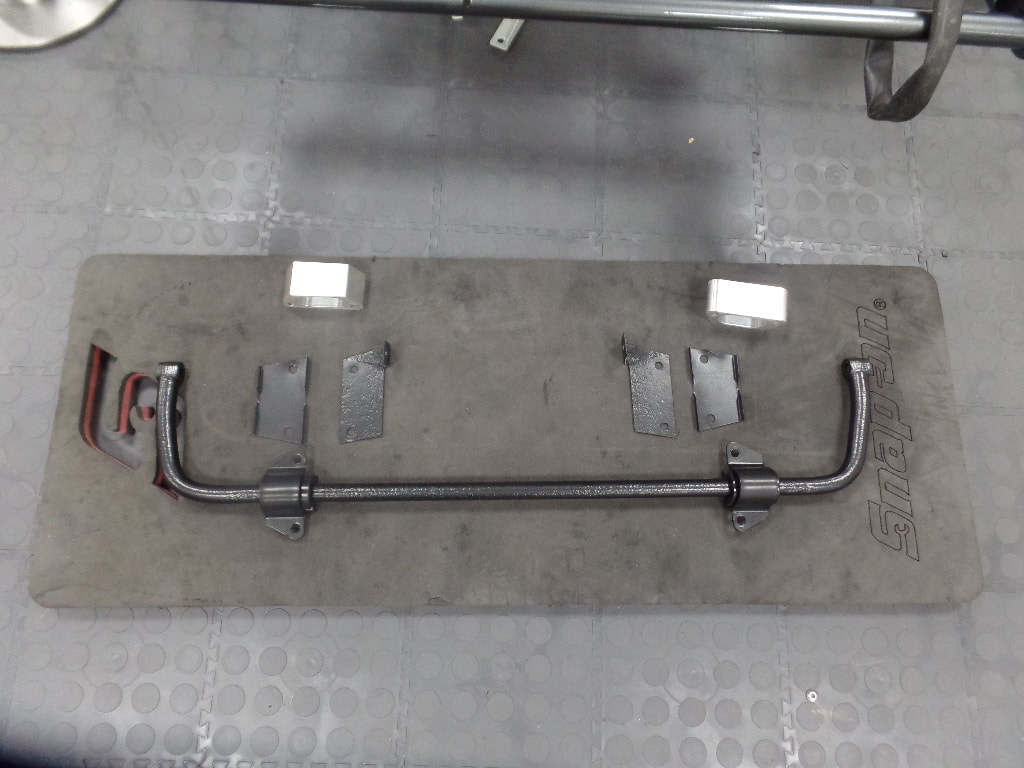

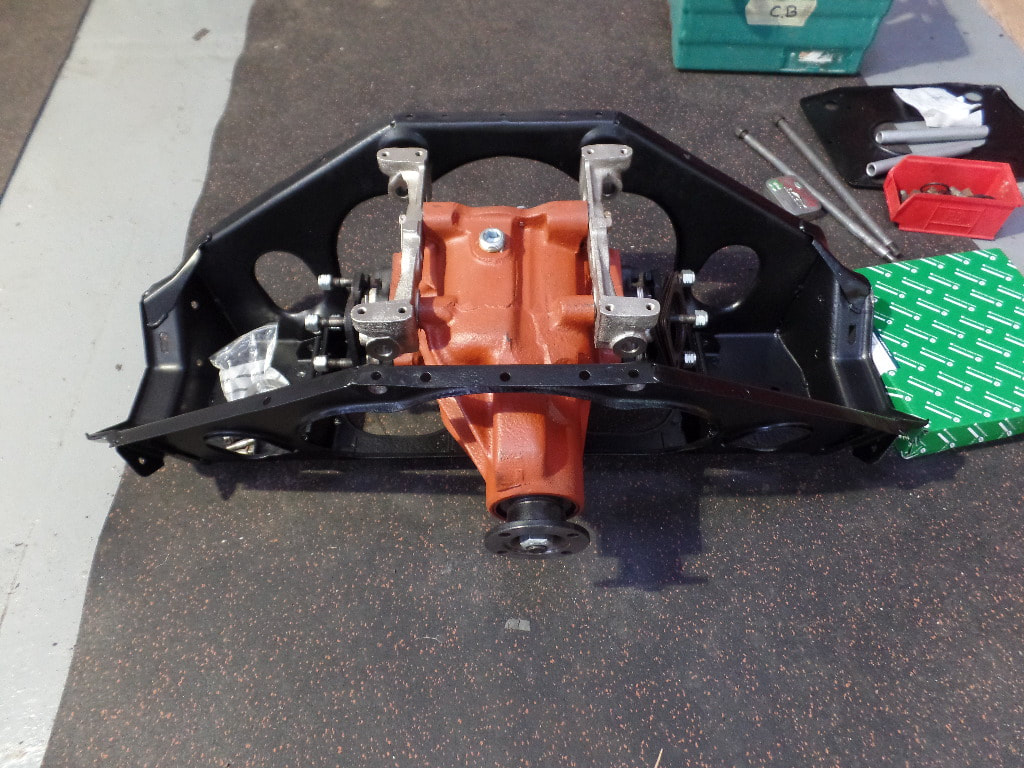

Rear axle built up this week.

Rear axle built up this week.

5th April 2019

The bodyshell is coming together nicely now and the doors have been reskinned and trial fitted.

The bodyshell is coming together nicely now and the doors have been reskinned and trial fitted.

1967 RHD Series 1 OTS

Brief for this car is a complete restoration.

Brief for this car is a complete restoration.

29th March 2019

The safe return of the re-conditioned 3.8 engine to the workshop.

The safe return of the re-conditioned 3.8 engine to the workshop.

22nd March 2019

Work is surging ahead now on the shell and the rear wings and tonneau panels are in position.

Work is surging ahead now on the shell and the rear wings and tonneau panels are in position.

1st March 2019

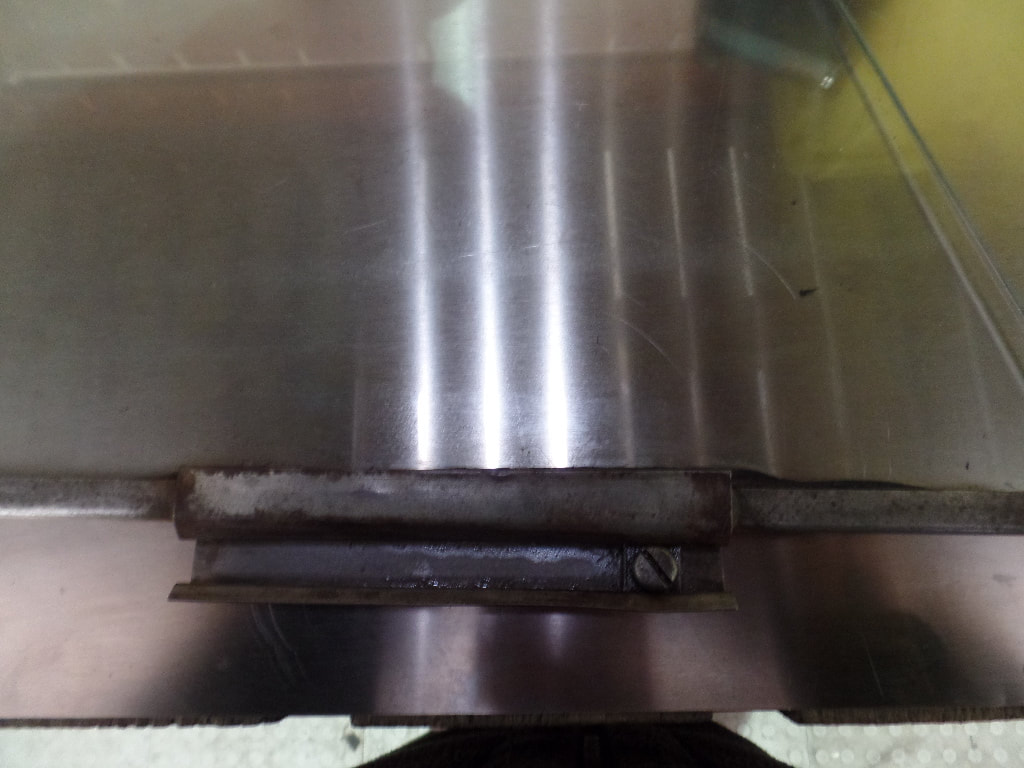

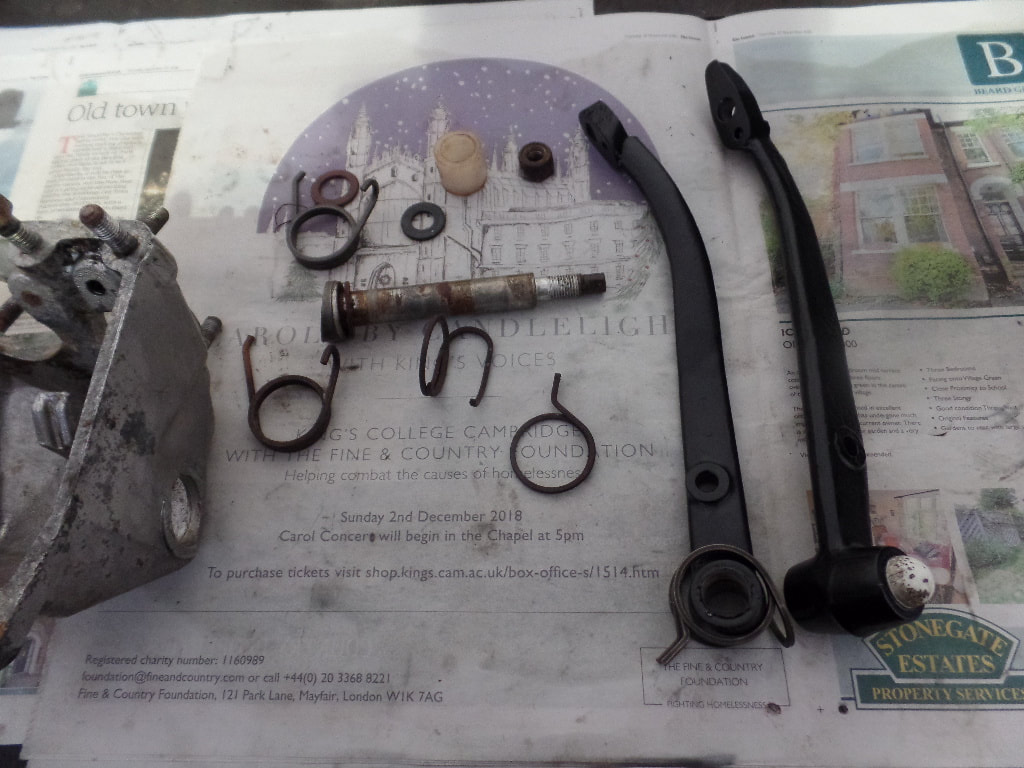

With the bodyshell in the bodyshop, we had to strip the bootlid springs down as they are needed for fitting up. They are now being blasted and primed prior to us rebuilding them with new springs. The dashtop vents have been stripped off ready for powdercoating and the drop glasses stripped and cleaned.

With the bodyshell in the bodyshop, we had to strip the bootlid springs down as they are needed for fitting up. They are now being blasted and primed prior to us rebuilding them with new springs. The dashtop vents have been stripped off ready for powdercoating and the drop glasses stripped and cleaned.

22nd February 2019

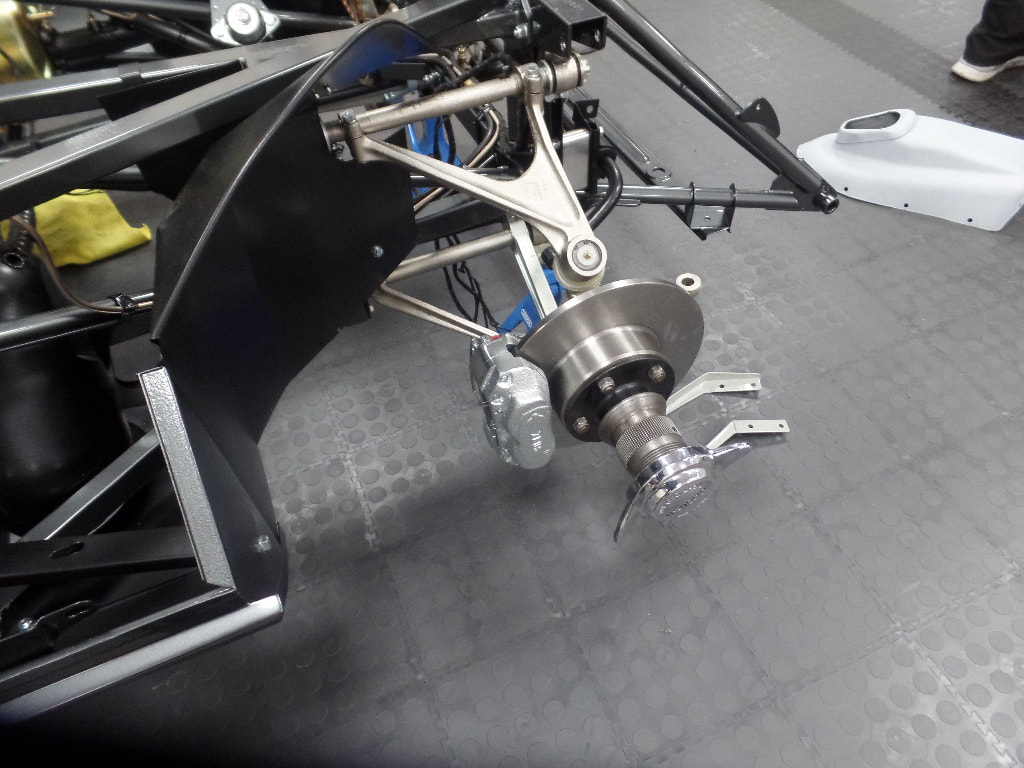

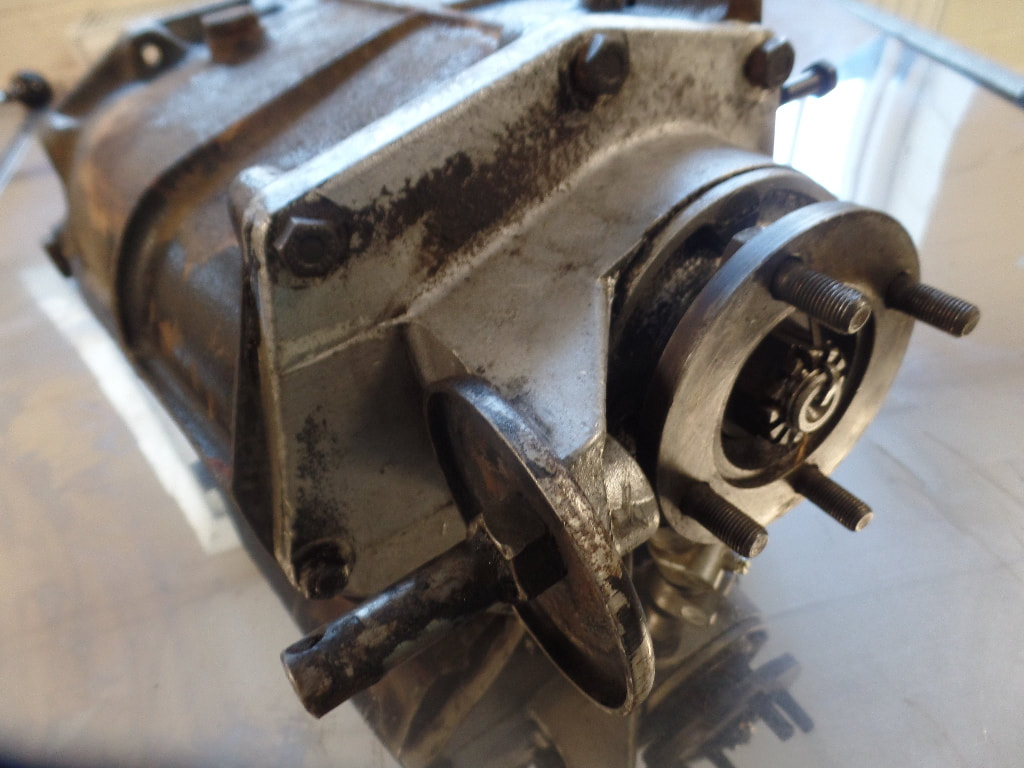

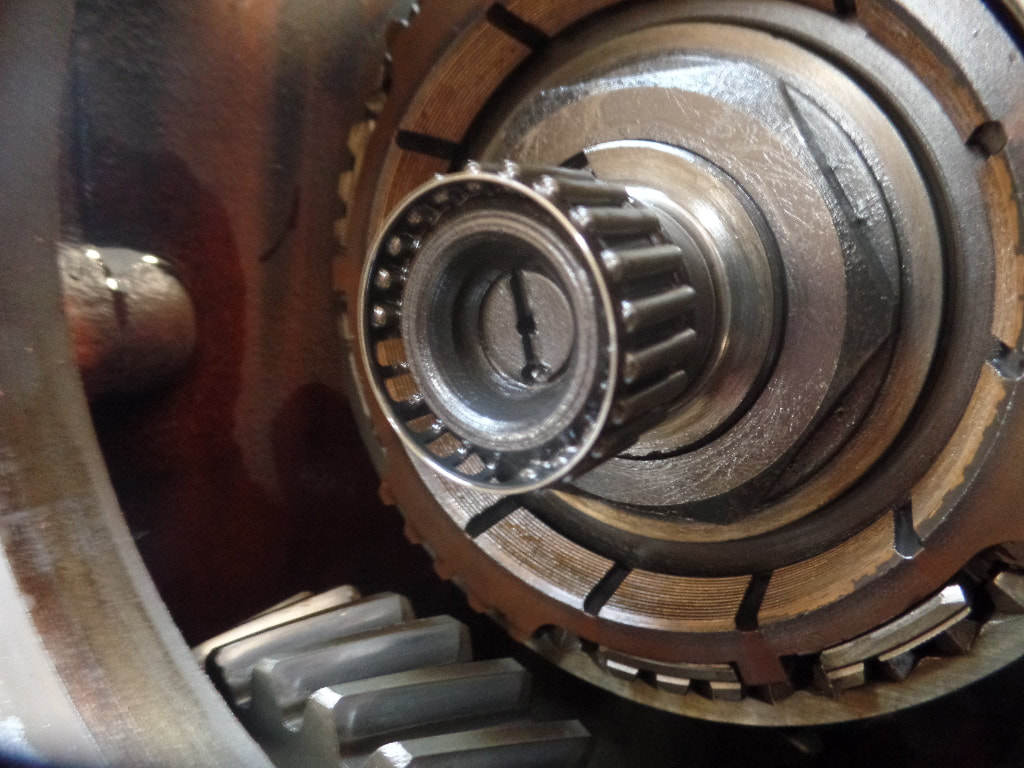

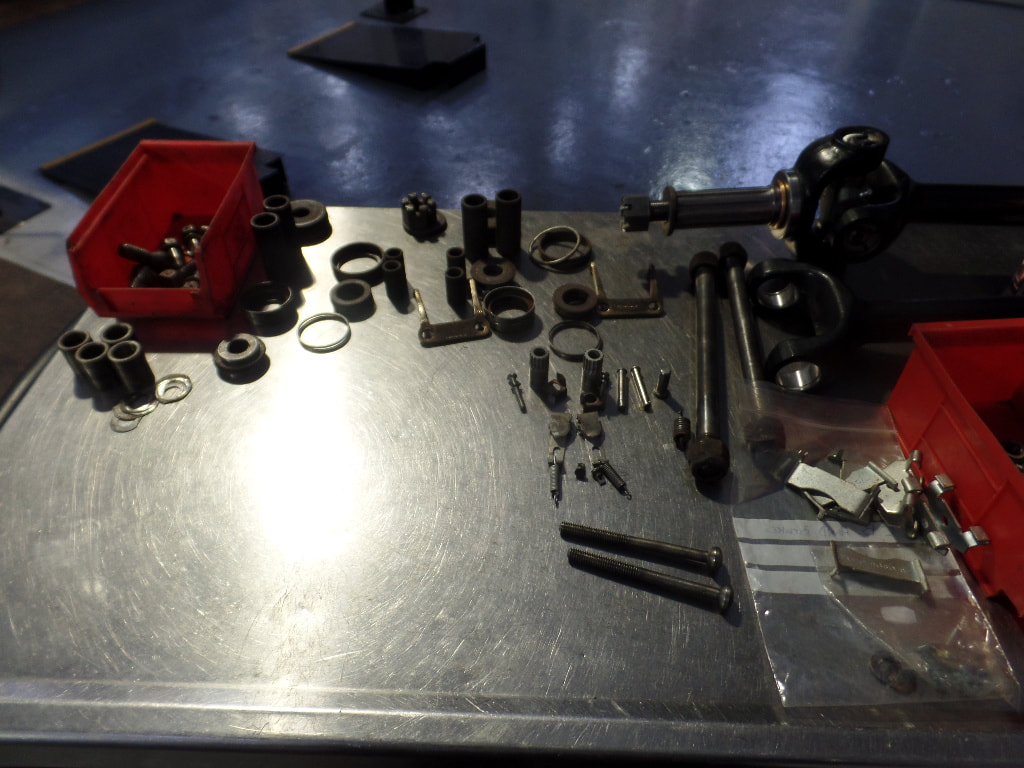

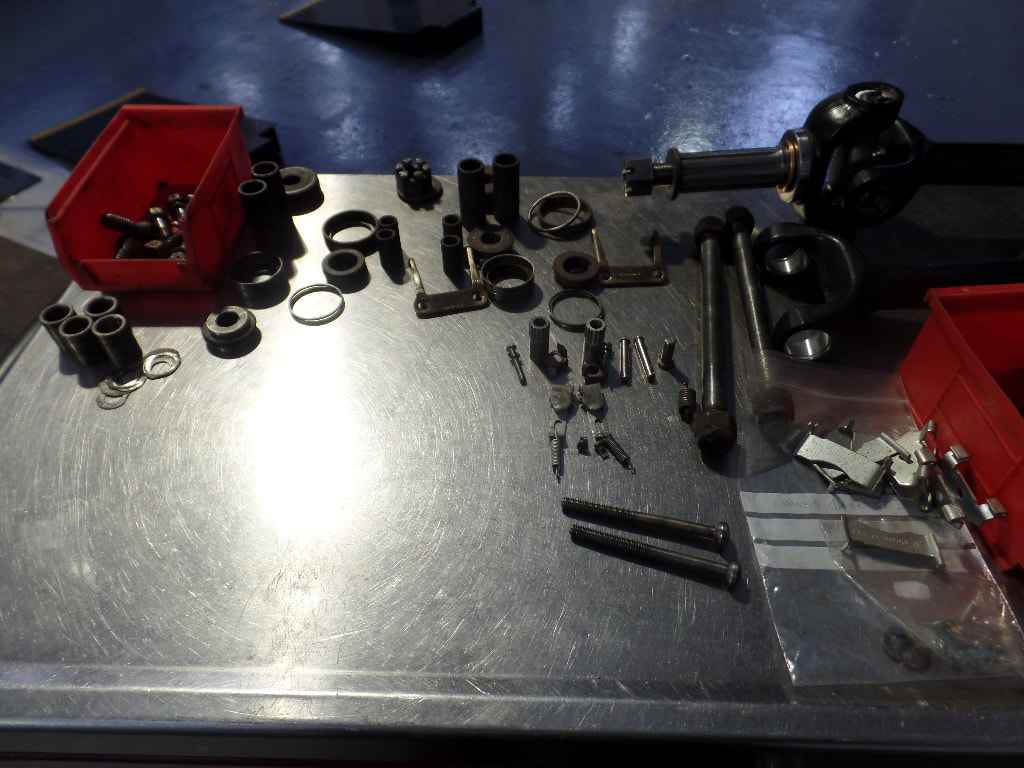

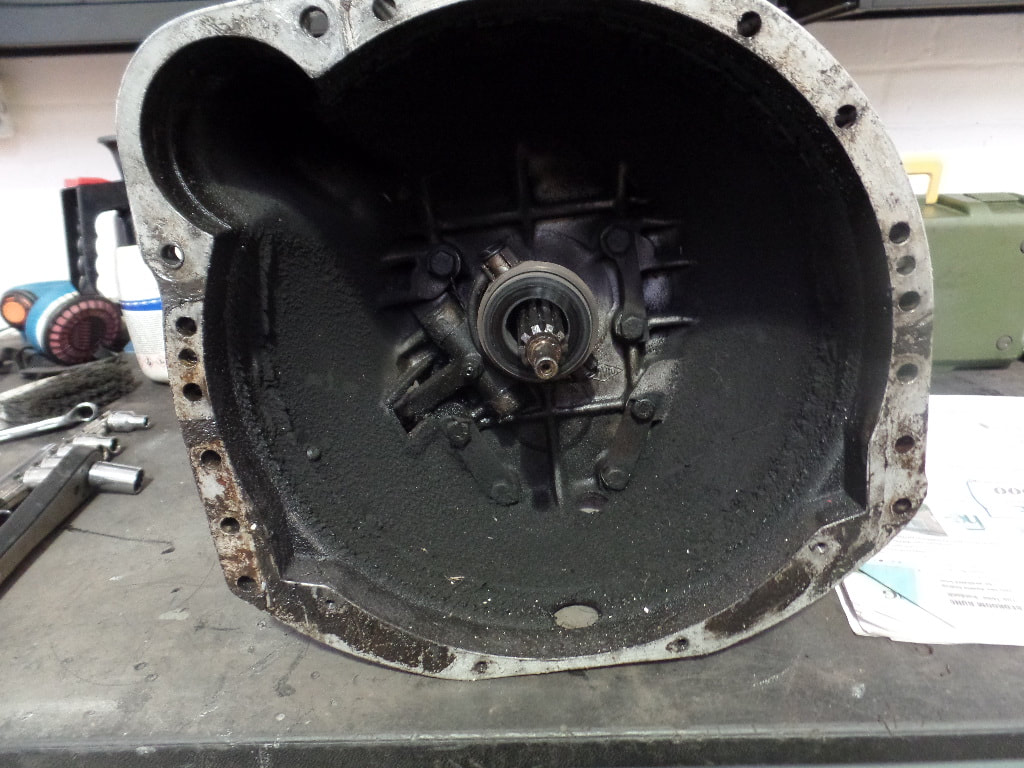

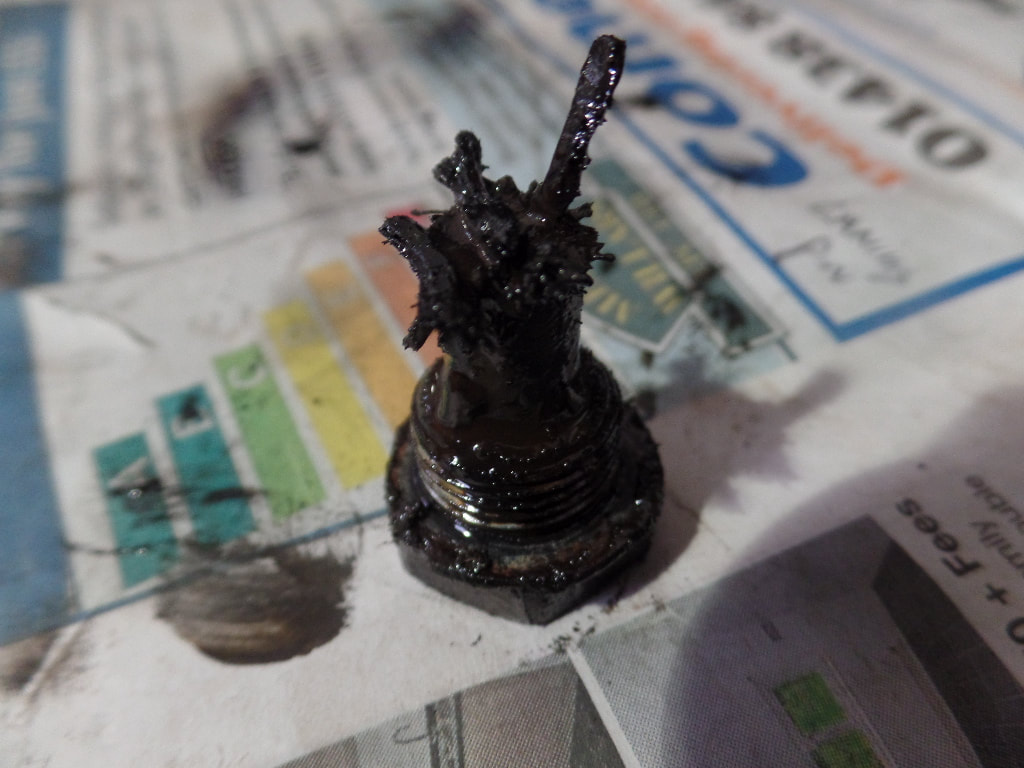

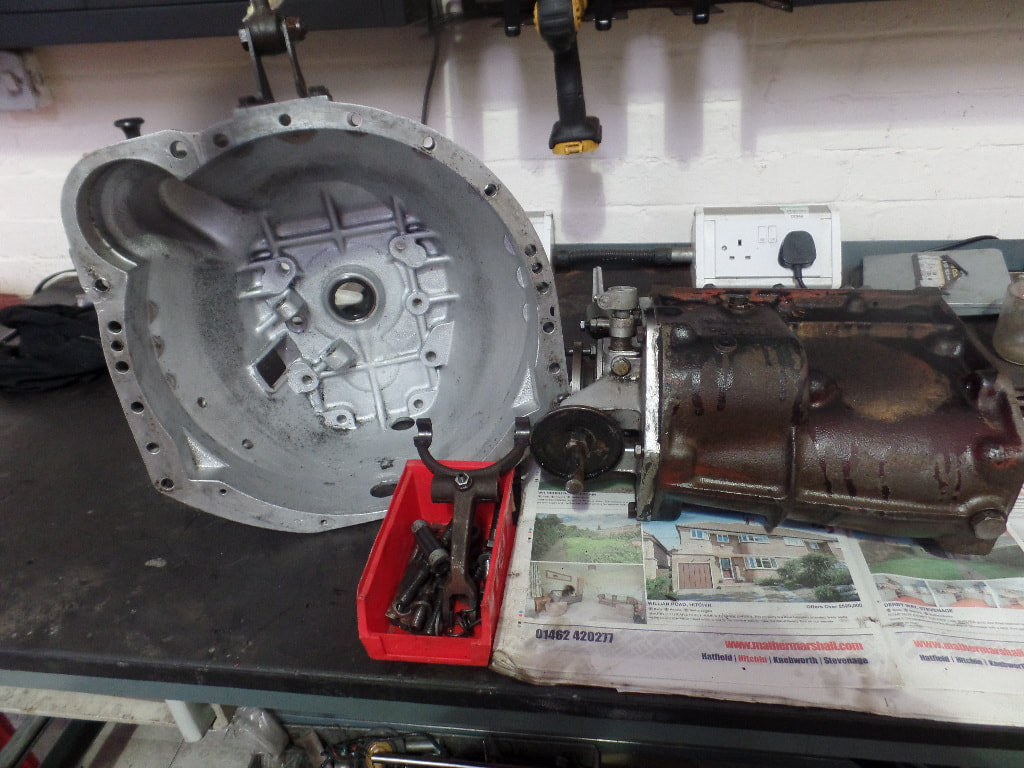

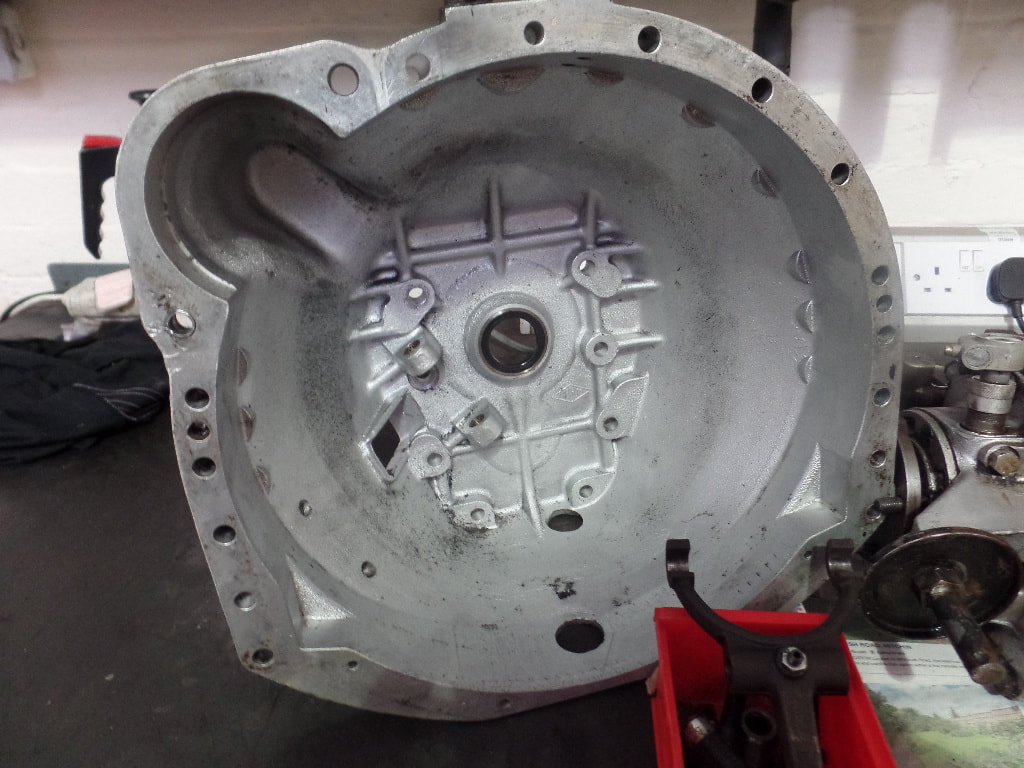

Lots more work on the S1 OTS and the pedal box is now finished. The rear axle is also built up with all the new bearings etc and rebuilt diff. The gearbox was split from the bell housing and everything cleaned up. The magnet on the sump plug did its job and caught the remains of a bearing breaking up.The front suspension bushes have also been fitted.

Lots more work on the S1 OTS and the pedal box is now finished. The rear axle is also built up with all the new bearings etc and rebuilt diff. The gearbox was split from the bell housing and everything cleaned up. The magnet on the sump plug did its job and caught the remains of a bearing breaking up.The front suspension bushes have also been fitted.

15th February 2019

The car is slowly coming back together and the shell is now finished. Just the out panels to fit and we will be ready for paint. The pedal box has been stripped and is ready for build up.

The car is slowly coming back together and the shell is now finished. Just the out panels to fit and we will be ready for paint. The pedal box has been stripped and is ready for build up.

8th February 2019

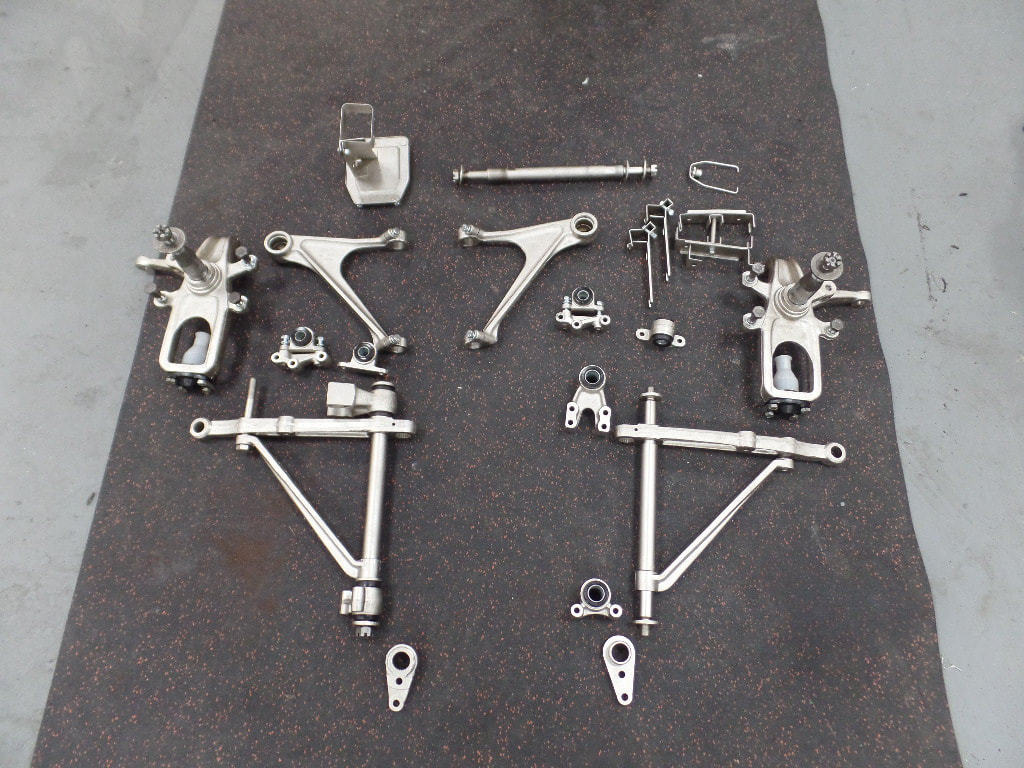

The powdercoaters and painters have been busy these last 2 weeks and we picked up the components for the Red S1 OTS. Its good when these items come back looking like new and we can start fitting up bushes etc.

The powdercoaters and painters have been busy these last 2 weeks and we picked up the components for the Red S1 OTS. Its good when these items come back looking like new and we can start fitting up bushes etc.

18th January 2019

The rear axle is now stripped and ready for delivery to the powder coaters and platers. We picked up the reconditioned diff (new bearings, seals etc) yesterday so we look forward to that being built soon.

The rear axle is now stripped and ready for delivery to the powder coaters and platers. We picked up the reconditioned diff (new bearings, seals etc) yesterday so we look forward to that being built soon.

7th December 2018

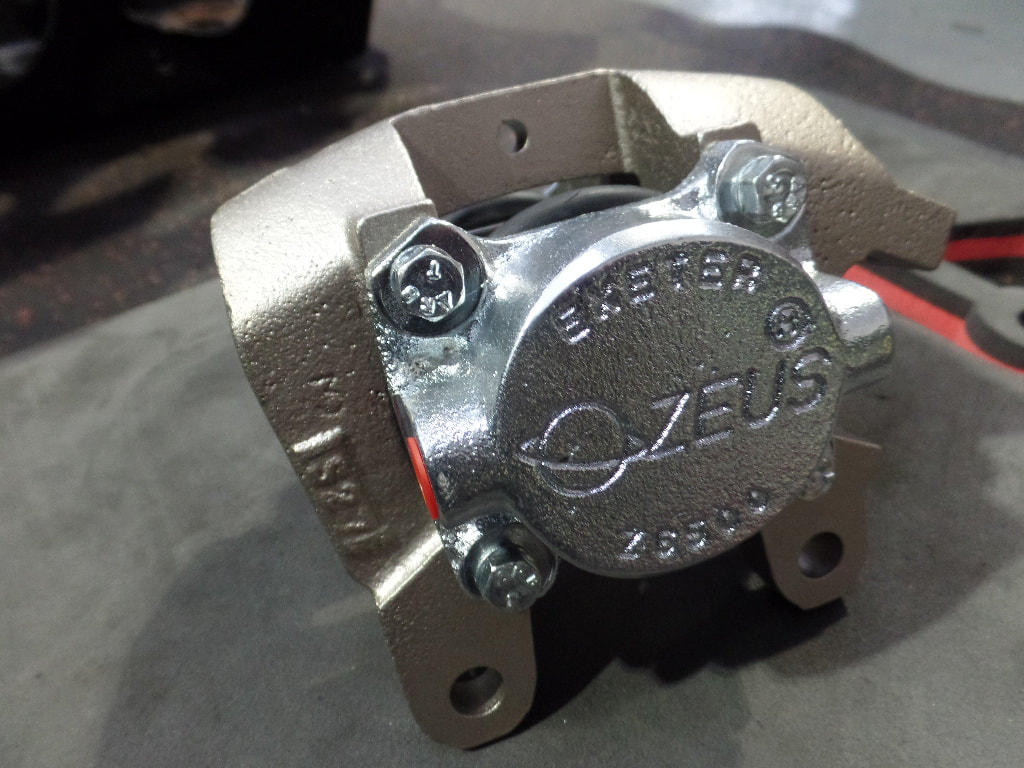

We have stripped the rear axle and have started rectifying problems along the way. The handbrake cage mounts had seized and broken off so these were replaced. There is some damage to the top shock absorber mounts so these will be repaired when we get it back from the blasters. The handbrake mechanism on one rear caliper had been well and truly bodged so we will replace the caliper.

We have stripped the rear axle and have started rectifying problems along the way. The handbrake cage mounts had seized and broken off so these were replaced. There is some damage to the top shock absorber mounts so these will be repaired when we get it back from the blasters. The handbrake mechanism on one rear caliper had been well and truly bodged so we will replace the caliper.

23rd November 2018

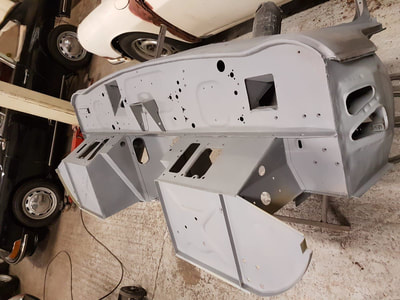

As we are moving the workshop in the next few weeks Leon decided that it would be a good idea to strip down the bonnet. Unbeknown to him there was a lot of repair work carried out and a number of panels were welded on. The belly pan and diaphragms are scrap. It is off to the blasters next week and we will see what we are left with.

As we are moving the workshop in the next few weeks Leon decided that it would be a good idea to strip down the bonnet. Unbeknown to him there was a lot of repair work carried out and a number of panels were welded on. The belly pan and diaphragms are scrap. It is off to the blasters next week and we will see what we are left with.

2nd November 2018

More work on the wiper motor. Stripping and cleaning carries on while the motor case now painted in the correct colour of silver hammer is waiting to have the field windings screwed in.

More work on the wiper motor. Stripping and cleaning carries on while the motor case now painted in the correct colour of silver hammer is waiting to have the field windings screwed in.

26th October 2018

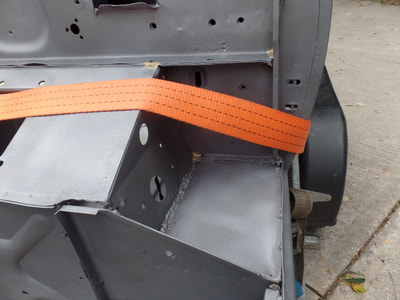

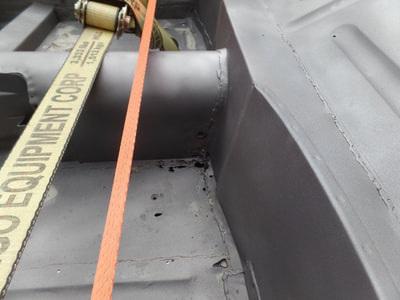

The bulkhead repairs are now complete. The wiper motor has been stripped and the relevant components sent off for powder coating.

The bulkhead repairs are now complete. The wiper motor has been stripped and the relevant components sent off for powder coating.

21st September 2018

We picked up the 65 OTS from the blasters in the week. It has revealed a lot of small (bad) repairs but now we know what we have to deal with.

We picked up the 65 OTS from the blasters in the week. It has revealed a lot of small (bad) repairs but now we know what we have to deal with.

14th September 2018

More front suspension stripping.

More front suspension stripping.

7th September 2018

The strip down continues and we turned our attention to the front suspension. Not a pleasant job but it all has to be broken down to its component level.

The strip down continues and we turned our attention to the front suspension. Not a pleasant job but it all has to be broken down to its component level.

31st August 2018

The engine has now been split from the gearbox and delivered down to our engine rebuilders this week.

The engine has now been split from the gearbox and delivered down to our engine rebuilders this week.

24th August 2018

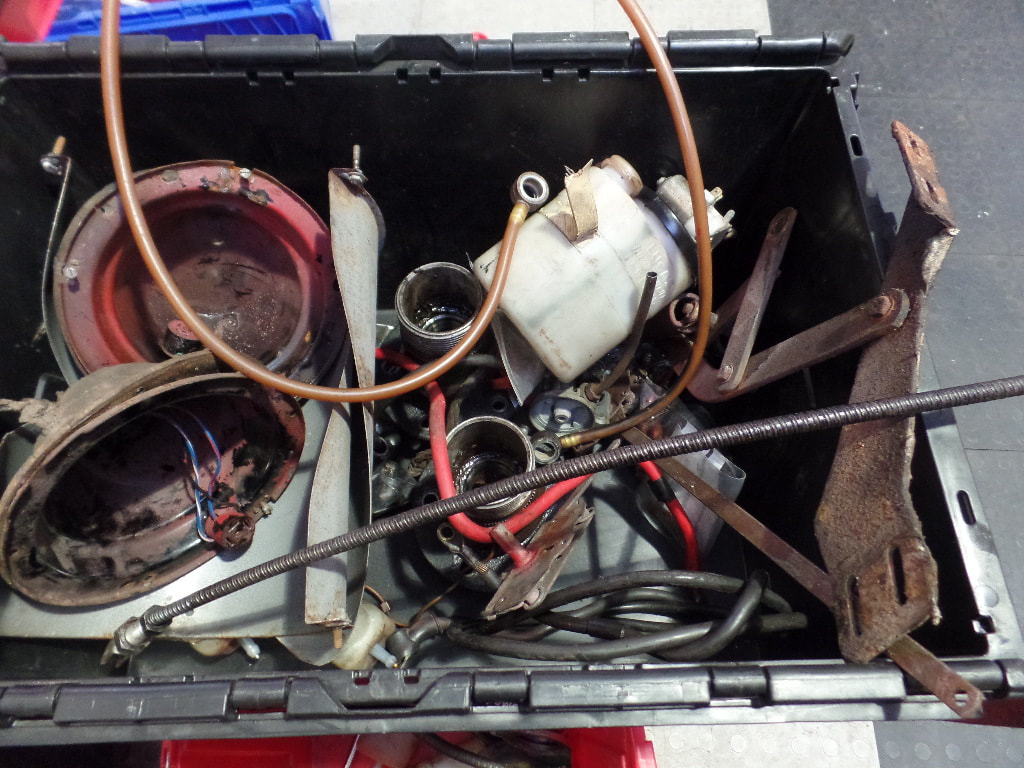

Car now stripped down ready for blasting. It didn't look bad but we saw beneath the shine to reveal a car that will need a lot of metalwork.

Car now stripped down ready for blasting. It didn't look bad but we saw beneath the shine to reveal a car that will need a lot of metalwork.