1969 Series 2 Fixed Head Coupe

Complete restoration of a rust free, Californian car. Conversion to right hand drive, re-trim in light grey, re-paint in Gunmetal and re-chrome. Completed February 2014.

Complete restoration of a rust free, Californian car. Conversion to right hand drive, re-trim in light grey, re-paint in Gunmetal and re-chrome. Completed February 2014.

26th February 2014

The car is now tuned and running well took a bit of research as to why the carbs were running rich and the issue was due to the needles being too high in the pistons.

The car is now tuned and running well took a bit of research as to why the carbs were running rich and the issue was due to the needles being too high in the pistons.

25th February 2014

Nearly finished the tuning of the carbs and they are now sealed and not leaking petrol.

Nearly finished the tuning of the carbs and they are now sealed and not leaking petrol.

5th December 2013

Rear chromes fitted on the hatch at last. We couldn't source any originals and I think we found the last pair of repros in the country! Bill of Allied Windscreens turned up when promised and did a fantastic job (again) as they weren't the easiest to fit - the material is thicker and doesn't follow the radii of the window well. The only problem was the 2 finishers; they were supplied in stainless steel (different colour to chrome) and were the wrong profile. All we have to do now is source to originals.

Rear chromes fitted on the hatch at last. We couldn't source any originals and I think we found the last pair of repros in the country! Bill of Allied Windscreens turned up when promised and did a fantastic job (again) as they weren't the easiest to fit - the material is thicker and doesn't follow the radii of the window well. The only problem was the 2 finishers; they were supplied in stainless steel (different colour to chrome) and were the wrong profile. All we have to do now is source to originals.

25th November 2013

Radio console now fitted properly - had to remove a lot of material from underneath the gearstick area on the centre console.

22nd November 2013

The number plate was stuck to the bonnet - always a fraught experience as the numbers and letters have to be glued individually to the backing plate and then glued in position on the bonnet. Very nerve wracking!

15th November 2013

With the car on the ramp for final greasing, I thought this angle looked good.

12th November 2013

Finally resolved the last big issue by unsticking the clutch. With the engine hot, it freed itself off. With the car on the ramp at last, we fitted the torsion bar shields and tightened up the front suspension. All that is left to do is finally tune the carbs and hand it over!

11th November 2013

Lots achieved today; finally tracked down the electrical fault - turned out to be in the ignition switch. Lots of head scratching later, turned out the wiring diagram was wrong. The radio console was installed and all is working well.

8th November 2013

Took a day off today but couldn't resist fitting the radio into the console. Installing a modern radio player into an old car doesn't always work aesthetically but this one looks good (in my view). We'll get it connected up next week.

5th November 2013

VAT inspection this morning - happily all OK and good to see that the HMRC want to work with small businesses and not hound them! Fitted the drivers seatbelt and picked up the special glue to re-stick the windscreen chromes.

30th October 2013

Finished off fitting the seats - now only a few small jobs to complete. The drivers door arm rest was fitted and the retainers for the boot boards.

Started work on the carb adjustment and will continue with that later.

Started work on the carb adjustment and will continue with that later.

29th October 2013

Built up the passenger seat and trial fitted the centre console. All looking good so far. One newly trimmed arm rest was put in place and the newly chromed eared spinners collected from the chromers and put on the car. They look great compared to the federal spinners.

Tomorrow should see the completion of the trim and we can focus on the carburettor set up.

Tomorrow should see the completion of the trim and we can focus on the carburettor set up.

26th October 2013

Went over to Holland to raise a friends V12 - it was running too low so a group of us hopped over the channel and set about changing the rear springs and re setting the front torsion bars.

We had finished the job within 3 hours and are delighted to report that the car is now riding higher and not scraping itself on every small stone on the road!

With that job under our belts, we turned out attention to another car, a 1962 FHC that had had some bonnet work carried out. Looks good after we helped refit it.

Meanwhile, back in the UK, I am reliably informed that the seats and console have been delivered for the grey FHC so its all steam ahead to get the interior fitted and finalised!

We had finished the job within 3 hours and are delighted to report that the car is now riding higher and not scraping itself on every small stone on the road!

With that job under our belts, we turned out attention to another car, a 1962 FHC that had had some bonnet work carried out. Looks good after we helped refit it.

Meanwhile, back in the UK, I am reliably informed that the seats and console have been delivered for the grey FHC so its all steam ahead to get the interior fitted and finalised!

24th October 2013

Engine running today! The timing was way out as a new distributor was fitted (having got rid of the emission control paraphernalia and fitted the triple carbs). The carbs needed some more fettling and we will get on to the final tuning next week.

There is still a water leak on the heater transfer pipe that runs behind the inlet manifold. We know what is causing it and that will be sorted next week by fitting a longer hose.

Finally, the radio console was stripped and will be repainted with the crackle paint. Hopefully the final pieces of trim will be delivered tomorrow....

There is still a water leak on the heater transfer pipe that runs behind the inlet manifold. We know what is causing it and that will be sorted next week by fitting a longer hose.

Finally, the radio console was stripped and will be repainted with the crackle paint. Hopefully the final pieces of trim will be delivered tomorrow....

22nd October 2013

Most of the day was spent working on the luggage board runners and fitting them in the car. Imperative that they are straight and line up on the 4 boards. Pleased to say that after constant measuring and re-measuring, we achieved that!

When we were happy that the boards were completed, we fitted the gasket that Andy at Hutsons had sent down and voila! No more more leaks. Final job of the day was to fit the bonnet landing pin rubbers and adjust the bonnet.

If the weather is fine tomorrow, we will look at finally starting the car.

When we were happy that the boards were completed, we fitted the gasket that Andy at Hutsons had sent down and voila! No more more leaks. Final job of the day was to fit the bonnet landing pin rubbers and adjust the bonnet.

If the weather is fine tomorrow, we will look at finally starting the car.

21st October 2013

Repaired the broken roof aerial mounting and fitted the tweeters (hidden just below the dash top).

Fuel lines now holding pressure (despite the fibre washers leaking!) now. Massive water leak from the thermostat housing extension on the front of the inlet manifold - turns out there was a problem with the gasket - good news as we feared the manifold was faulty.

Fuel lines now holding pressure (despite the fibre washers leaking!) now. Massive water leak from the thermostat housing extension on the front of the inlet manifold - turns out there was a problem with the gasket - good news as we feared the manifold was faulty.

18th October 2013

Finished off under bonnet and the engine now cranks over. Cut the vacuum pipes to length ready for fitting. Glued the windscreen chrome in place (note the official Jaguar tool to hold it in down!).

Phil the trimmer is bringing the boot boards over in the morning so all that will be left is the seats to fit.

Next week should see the car completed and ready for testing!

Phil the trimmer is bringing the boot boards over in the morning so all that will be left is the seats to fit.

Next week should see the car completed and ready for testing!

17th October 2013

Finalised the wiring today with the exception of the starter motor - think it is a bad earth so we'll trace that down tomorrow. The handbrake and brake fluid level warning lights were sorted out along with the cooling fans. The only circuit not checked yet is the charging - cant do that until the engine is fired up.

Tomorrow should see the car finished and ready for engine run and road testing next week.

I have tried to capture the panel fit in the following shots - they are all factory!

Tomorrow should see the car finished and ready for engine run and road testing next week.

I have tried to capture the panel fit in the following shots - they are all factory!

15th October 2013

More small jobs comleted today. Sunvisors fitted, doors adjusted, B post rubbers stretched and glued in place. The new plenum and intake arrived for the triple carb conversion - just need the air filter canister now.

The interior light was wired up along with the door switch on the drivers side. The passenger side is proving to be a bit more tricky as Jaguar were experimenting with different switches and this one ended up in the bin!.

The demister tubes were connected to the dashtop.

The interior light was wired up along with the door switch on the drivers side. The passenger side is proving to be a bit more tricky as Jaguar were experimenting with different switches and this one ended up in the bin!.

The demister tubes were connected to the dashtop.

14th October 2013

Rear door trimmed and glass fitted (thanks to Bill of Allied Windscreens and Carlos of Grahams Windscreens). By the time I'd made the tea it was in with only the spreader rubber to fit!

Lots of smaller jobs completed:

Finally, the intake for the carbs and boot board strengthener were taken for powder coating.

Lots of smaller jobs completed:

- Hinge and Latch covers to rear hatch.

- Drivers door card

- Front seat mountings

- Carpet studs

- Glove box lid fittings.

Finally, the intake for the carbs and boot board strengthener were taken for powder coating.

11th October 2013 (Pt II)

Lots of small, finishing jobs completed today. New tailgate screws arrived so we were able to build it up prior to fitting. Luggage rails also screwed in place. Dashboard side chromes fitted after making new plastic inserts.

Mirror mounting bonded in place and the LHS windscreen side chrome bonded in place. Glovebox lid handle fitted.

Rear hatch stay screwed to body.

Phil the trim is coming over tomorrow morning to finish off the rear hatch. We can then get the boys back to fit the rear screen.

Mirror mounting bonded in place and the LHS windscreen side chrome bonded in place. Glovebox lid handle fitted.

Rear hatch stay screwed to body.

Phil the trim is coming over tomorrow morning to finish off the rear hatch. We can then get the boys back to fit the rear screen.

10th October 2013

Doors sprayed with Waxoyl prior to sealing and trimming. Drivers door card fitted but will have to be removed tomorrow as we aren't happy with the fit. Drivers side trim chrome fitted.

Final photo shows an upgrade we recommend be fitted to all our E Types; wiper delay module. Absolutely essential if you use your car!

Final photo shows an upgrade we recommend be fitted to all our E Types; wiper delay module. Absolutely essential if you use your car!

9th October 2013

Passenger door built and door card fitted. Just the latch to adjust now. The new mirror was fitted to the passenger side and the mounting holes drilled for the drivers door. This took time as we didn;t want to risk scratching the new paint! Both mirrors are now on the car and it looks great.

The drivers door had to be stripped in order to change the window channel rubber - the original one supplied was too thick which meant the window was difficult to wind up.

Tomorrow we'll finish off the drivers door and finalise the latch adjustment.

The drivers door had to be stripped in order to change the window channel rubber - the original one supplied was too thick which meant the window was difficult to wind up.

Tomorrow we'll finish off the drivers door and finalise the latch adjustment.

8th October 2013

Wiper motor connected to the rack and wipers fitted. All working ok now. The new window channel arrived and we were able to build the passenger door. The decision to use the original mounting screw holes has paid off as the fit of the chrome and trim is perfect. The new rubber channel means that the window moves up and down freely. Just the door card, plastic sheet and mirror to fit.

All we have to do is remove the drivers door frame and replace the channel in there!

Rubber buffers were fitted to the fuel filler area - failure to fit them will cause the lid to wear the paint in that area away.

All we have to do is remove the drivers door frame and replace the channel in there!

Rubber buffers were fitted to the fuel filler area - failure to fit them will cause the lid to wear the paint in that area away.

7th October 2013

With the workshop lighting replaced, we trial fitted the new passenger door mirror and checked it met customer requirements! It did and the drivers side is now on order. The windscreen chromes were installed and the RHS pillar chrome left overnight to bond in place.

The A post harduras were glued in place along with the footwell carpets and sound deadening.

Finally, we worked out why the wiper motor wouldn't switch off. When you rebuild the motor, best make sure the limit switch is screwed properly back in place! (Now I wonder who did that!).

The A post harduras were glued in place along with the footwell carpets and sound deadening.

Finally, we worked out why the wiper motor wouldn't switch off. When you rebuild the motor, best make sure the limit switch is screwed properly back in place! (Now I wonder who did that!).

4th October 2013

The nylon bushes were pressed into the rear hatch allowing the badges to be properly attached. The badge for the motif bar arrived so that was also fitted.

3rd October 2013

Feels like we have been trimming for most of our lives! Fortunately, we are just about finished and we only have the A post harduras to glue down now that we have fitted the speaker grilles.

Its looking nice now and we are expecting the seats and console in the next week.

Its looking nice now and we are expecting the seats and console in the next week.

2nd October 2013

Built up the luggage board but am trying to source the chrome machine screws. We want to replace them with stainless steel so our supplier is on the case. Only need to fit the rubber strips and carriers to complete it.

The board retainers were riveted in place on the wheel arches - we have used the existing fixing holes so there are no alignment problems.

The passenger door was fitted and latches well. Only final adjustment to carry out before continuing with the fit up.

The board retainers were riveted in place on the wheel arches - we have used the existing fixing holes so there are no alignment problems.

The passenger door was fitted and latches well. Only final adjustment to carry out before continuing with the fit up.

1st October 2013

Completed the B post trimming on the drivers side and fitted the drivers door top trim and chrome.

30th September 2013

Bill and Carlos of Aliied Windscreens in Letchworth arrived today to fit the front screen. Fantastic job and it went well. They were very impressed with the windscreen lip on the car - hadnt seen one as clean as this one in years!

The drivers door fit was finalised and sun-visors adjusted. We also carried on with some trimming.

Tomorrow, the trimmer is coming over with some more panels and hopefully finish off the rear hatch (the boys can then come back and fit the glass).

Some real progress being made now!

The drivers door fit was finalised and sun-visors adjusted. We also carried on with some trimming.

Tomorrow, the trimmer is coming over with some more panels and hopefully finish off the rear hatch (the boys can then come back and fit the glass).

Some real progress being made now!

27th September 2013

Drivers door fitted but needs shimming at the bottom of the hinge to get the closing smoother. The retaining panel for the luggage boards was installed and some minor panels trimmed.

Finally, arranged the fitting of the windscreen for Monday morning. Can just about see the finishing line now!

Finally, arranged the fitting of the windscreen for Monday morning. Can just about see the finishing line now!

25th September 2013

Spent most of the day installing the drivers door. Shut lines are good but the new rubbers need to bed in. With the door built, the weight has moved the door slightly so will have to realign first thing before continuing.

Phil bought over some trim which means we can start to tidy up the interior. Just the boot boards, B post panels, rear hatch trim, seats and centre console to go. Along with starting the engine, sorting out the wiper motor limit switch, fitting the screens and the passenger door, the car will be good to go! Shouldn't be long now.

Phil bought over some trim which means we can start to tidy up the interior. Just the boot boards, B post panels, rear hatch trim, seats and centre console to go. Along with starting the engine, sorting out the wiper motor limit switch, fitting the screens and the passenger door, the car will be good to go! Shouldn't be long now.

24th September 2013

After a long weekend at Spa Francochamps covering 1200 miles in the E Type, it was back down to earth again in the workshop. The air cleaner lower mounting bracket was put in place and fitted perfectly. The drivers door was bolted in and adjusted. Now we have to spend time to get the latching set up prior to building the internals.

A mighty V12 turned up tonight for check over and report. Looking forward to driving a V12 again - they are such a fantastic engine.

Finally, have a look at the 'E Type Life' page for some pictures of our Spa weekend.

A mighty V12 turned up tonight for check over and report. Looking forward to driving a V12 again - they are such a fantastic engine.

Finally, have a look at the 'E Type Life' page for some pictures of our Spa weekend.

19th September 2013

Fitted the dashtop to the Fixed Head today. Looks good. Cut the hole in the footwell hardura for the speaker and used mastic to glue it in place. Finally, the 'works hack' is ready for an 0530 start in the morning as we head off to Spa for a long weekend. Weather forecast is good, company excellent and food sublime. What could possible go wrong?......

10th September 2013

RThe newly trimmed dashtop was delivered and looks great. Picture shows it resting in place. Work on checking out the wiring continued on the FHC and I am pleased to report that all is now working with the exception of the wiper motor and cooling fans. The wiper motor was removed and bench tested and found to be working properly which means that has to be a problem .with the linkage fouling in the bulkhead. The relay is being activated on the fans and tomorrow we'll have a look at the live going to the motors.

9th September 2013

Day spent checking out the electrics. A few minor problems rectified but seem to have a major issue with the wiper motor. We'll remove that later this week to investigate.

Andy sent the part needed for the carbs so that was fitted along with the fuel rail and pipe. All is ready now to fire the engine but we won't be doing that until the wiring check is complete.

Andy sent the part needed for the carbs so that was fitted along with the fuel rail and pipe. All is ready now to fire the engine but we won't be doing that until the wiring check is complete.

6th September 2013

More trimming today but it is now pretty much done. Only the carpets, doors and rear hatch to finish off. The third photo shows one of the rubber bump stops fitted to the tailgate - often missing.

Fitted the battery today for the first time - nothing sparked or caught fire so that is good news. The downside to it is that nothing worked! Oh well, must be something pretty fundamental.

Fitted the battery today for the first time - nothing sparked or caught fire so that is good news. The downside to it is that nothing worked! Oh well, must be something pretty fundamental.

5th September 2013

Another hard day fighting the trim but it is slowly coming together now. The first photo shows 2 hidden trim clips. We needed some of the type on the right and spent an hour or so trying to track some down - no-one had any so we returned empty handed.

In between trimming, I stripped the glue off the luggage retainer rail (not a pleasant job) and it is now ready for trimming. The front indicator lenses arrived so, apart from the badge bar, that is the front finished.

Finally, the newly trimmed and re-chromed grab handle was bolted down.

In between trimming, I stripped the glue off the luggage retainer rail (not a pleasant job) and it is now ready for trimming. The front indicator lenses arrived so, apart from the badge bar, that is the front finished.

Finally, the newly trimmed and re-chromed grab handle was bolted down.

4th September 2013

More progress on the Fixed Head today, fitted the carb overflow pipes and the RHS rear quarter light. Really fits well and finishes off that part of the car nicely.

Plans to start the engine were scuppered when we couldnt find the choke connection at the carb end. A quick call to Hutsons means we will have one on Friday.

Plans to start the engine were scuppered when we couldnt find the choke connection at the carb end. A quick call to Hutsons means we will have one on Friday.

3rd September

The remaining trim panels had arrived so it was time to get trimming!

30th August 2013

Today spent trimming difficult bits! Got the rear bulkhead and sill covers finished. Ordered the plywood for the boot boards and finished some more underbonnet work. Doesn't sound like much but it took a long time!

29th August 2013

First of all a correction to yesterdays update; Mareks car is fitted with MegaSquirt-3 which comprises the injection and ignition management.

Lots of trimming carried out today starting with the drivers side sill, underfelt and cross member carpet. The blanking panels in the rear wheelarches were trimmed and fitted. (We had to re-make one as the plywood had delaminated).

The tailgate was bolted in and the fit is fantastic (well it is factory after all).

Some more work was completed under the bonnet (choke and coolant pipe connections).

Finally, the luggage boards were retrieved and inspected. Bad news is the wood has dried out so we will have to fit new.

Lots of trimming carried out today starting with the drivers side sill, underfelt and cross member carpet. The blanking panels in the rear wheelarches were trimmed and fitted. (We had to re-make one as the plywood had delaminated).

The tailgate was bolted in and the fit is fantastic (well it is factory after all).

Some more work was completed under the bonnet (choke and coolant pipe connections).

Finally, the luggage boards were retrieved and inspected. Bad news is the wood has dried out so we will have to fit new.

28th August 2013

Started the day with Phil the Trimmer coming over to cover the wheel arches and drop off the newly trimmed cantrails and door tops. All looks good and it shouldn't be long before we get it finished. Started building up the door frames and fitting the glass in anticipation of fitting the doors.

I managed to get the front bumper fitted as well as the triple carbs. Wont be long now before we fire it up!

I managed to get the front bumper fitted as well as the triple carbs. Wont be long now before we fire it up!

27th August 2013

Back in the workshop and the fuel tank was fitted and plumbed in. A really easy job which was surprising as this normally takes hours - must be the fact that it is the original tank being refitted..

The LHS side light was wired up and screwed in place.

We collect the front over riders tomorrow so we'll get the front bumper fitted. Should be a lot of progress this week as the trim is starting to be delivered.

The LHS side light was wired up and screwed in place.

We collect the front over riders tomorrow so we'll get the front bumper fitted. Should be a lot of progress this week as the trim is starting to be delivered.

23rd August 2013

Finished off the headlights and wired them in. Fitted the new coil.

The sunvisors arrived back today so they were installed - just a bit of tidying up to do on the roof lining.

Finally one of the sidelights was wired and screwed in place, just the UK lenses to buy now.

Next week we should see the doors installed and built.

The sunvisors arrived back today so they were installed - just a bit of tidying up to do on the roof lining.

Finally one of the sidelights was wired and screwed in place, just the UK lenses to buy now.

Next week we should see the doors installed and built.

21st August 2013

Cleaned out the threads for the front bumper and then fitted the RHS headlight chrome. Really important this fits well as it is highly visible. Took a long time but the end result was worth it.

Took the front over riders and lower windscreen chrome back to the chromers for re-work.

Took the front over riders and lower windscreen chrome back to the chromers for re-work.

20th August 2013

Being such a hot day, it was time to Waxoyl the car. Leaving the wax in the sun for a few hours warmed it up nicely. The bonnet was sprayed first followed by the boot area.

With that job complete (at least my hands shouldn't rust for a few years!) we started ftting the headlamp chrome trim and 'sugar scoop'. Having got the bucket riveted in place using the special rivets that the trim snaps onto, they all had to be removed as the trim wouldn't stay in place. Andy at Hutsons warned me about this and the answer is to fit small washers under the rivets in order to raise them up a small amount.

With this done, the trim snapped into place. We couldn't fit the headlight though as the person who cleaned the headlamp bucket has lost the adjusters!

We'll do the other side tomorrow - shouldn't take long now we know what we are doing!

With that job complete (at least my hands shouldn't rust for a few years!) we started ftting the headlamp chrome trim and 'sugar scoop'. Having got the bucket riveted in place using the special rivets that the trim snaps onto, they all had to be removed as the trim wouldn't stay in place. Andy at Hutsons warned me about this and the answer is to fit small washers under the rivets in order to raise them up a small amount.

With this done, the trim snapped into place. We couldn't fit the headlight though as the person who cleaned the headlamp bucket has lost the adjusters!

We'll do the other side tomorrow - shouldn't take long now we know what we are doing!

19th August 2013

Bonnet chrome beads, gutter trims and door rubbers fitted - very sticky day! The sunvisors were sent off to the trimmers for them to fit them to the chrome mounts.

The carbs were built and only need the return springs, choke bracket and spring mounts to complete - we'll be able to attach them to the engine when they arrive.

The carbs were built and only need the return springs, choke bracket and spring mounts to complete - we'll be able to attach them to the engine when they arrive.

16th August 2013

Number plate light fitted along with the drain pipe for fuel tank and the air intake for the heater. Picked up nickel plating for carbs. The new number plate was fitted and the overall result much neater than the original!

13th August 2013

Very busy here at the moment with a number of cars passing through. We fitted the clam shells to the rear lights and trial fitted the headlight housings into the bonnet.

12th August 2013

Worked on the bonnet today, fitted the grille, landing pins, wiring loom, strut, safety catch, radiator stone guard and mudguard rubbers.

The fuel tank was sealed with POR 15 and left to cure for re-fitting later this week. The last batch of chroming was collected and we dropped off the carburettor parts for nickel plating.

The fuel tank was sealed with POR 15 and left to cure for re-fitting later this week. The last batch of chroming was collected and we dropped off the carburettor parts for nickel plating.

9th August 2013

Collected the bonnet today at last. No problems in transporting or fitting it to the car. Just the final lining up to do now.

The new trim kit arrived along with the tank sealant so it is going to be a busy week!

The new trim kit arrived along with the tank sealant so it is going to be a busy week!

8th August 2013

Andy the ICE man turned up today (in a very nice AM Vantage) to lay the wiring in for the speakers. Picked up the fuel tank from the powder coaters - once again the boys at Full Range Finishing did us proud and turned it around quickly. All we need now is the sealant before we can refit it.

The roof lining was trimmed along one side and rear edge and we're half way through the other side. Finally, another carb was built in preparation for firing it up in the next few days.

Bonnet being collected tomorrow - this time in the right van!

The roof lining was trimmed along one side and rear edge and we're half way through the other side. Finally, another carb was built in preparation for firing it up in the next few days.

Bonnet being collected tomorrow - this time in the right van!

7th August 2013

Lots of running around today. Started by looking at a S2 bonnet in London then picked up the fuel tank from being cleaned. It is absolutely spotless inside and out now. Dropped it off at the powder coaters along with the demister vents.

Back in the workshop, spent a happy couple of hours soda blasting the carbs. The first one is built but we are waiting for new jets prior to mounting onto the inlet manifold.

Hopefully the tank will be ready tomorrow so that will be sealed with POR15 and installed back in the car.

Back in the workshop, spent a happy couple of hours soda blasting the carbs. The first one is built but we are waiting for new jets prior to mounting onto the inlet manifold.

Hopefully the tank will be ready tomorrow so that will be sealed with POR15 and installed back in the car.

6th August 2013

Busy day working on some of the detail stuff. New rear lights arrived (at last) and they were fitted. Note that these are from a Lotus Elan S4 and have the integral reversing light within the cluster. (The S2 had separate lights bolted to the rear bumper). Coupled with a S1 centre exhaust, no stainless steel number plate panel and rectanguar, standard number plate, this should tidy up the back end nicely.

The dash panel was retrieved from storage and the demister vents removed for powder coating. A new vinyl top was ordered and this will be fitted by our trimmer, Phil, in the next week or so.

Small blanking grommets were fitted to the boot floor and the choke and heater knobs were resprayed with 'crinkle' paint.

Finally, the heater control knobs were fitted and just need lining up (bending) to make perfect.

The dash panel was retrieved from storage and the demister vents removed for powder coating. A new vinyl top was ordered and this will be fitted by our trimmer, Phil, in the next week or so.

Small blanking grommets were fitted to the boot floor and the choke and heater knobs were resprayed with 'crinkle' paint.

Finally, the heater control knobs were fitted and just need lining up (bending) to make perfect.

5th August 2013

Some days you just shouldn't get out of bed. Today was one of them. Went to collect the bonnet which looks fantastic only to find that the van was too small to put it in the back. The measurements I was given were for the sides of the van and didn't account for the door opening. Upshot is that we had to leave empty handed.

After a fruitless 300 mile journey, we returned the van, rebooked a bigger one for Friday and got back on to the cleaning of the fuel tank. We made the decision to cut a hole in the bottom of the tank in order to clean it out properly and then find a welder to weld the plate back. During discussions with someone prepared to do the work, it was suggested that we talk to a plating company to get them to clean the tank out without cutting any holes. We pick up the tank on Wednesday.....

Collected the inet manifold and carb dashpots from the polishers. Look great! Stripped the fuel gauge sender down and freed it up.

After a fruitless 300 mile journey, we returned the van, rebooked a bigger one for Friday and got back on to the cleaning of the fuel tank. We made the decision to cut a hole in the bottom of the tank in order to clean it out properly and then find a welder to weld the plate back. During discussions with someone prepared to do the work, it was suggested that we talk to a plating company to get them to clean the tank out without cutting any holes. We pick up the tank on Wednesday.....

Collected the inet manifold and carb dashpots from the polishers. Look great! Stripped the fuel gauge sender down and freed it up.

2nd August 2013

Cleaned and painted the armrests in light grey -turned out great. The front and rear screens were cleaned in preparation for installation at a later date. The clutch hydraulic pipe was made and fitted. Clutch bled and adjusted.

Fanbelts installed along with the RHS lower splash shield. The bonnet plug was soldered up and finally, the bonnet hinge pins cleaned and greased ready for bonnet installation on Monday. A good week!

Fanbelts installed along with the RHS lower splash shield. The bonnet plug was soldered up and finally, the bonnet hinge pins cleaned and greased ready for bonnet installation on Monday. A good week!

1st August 2013

Final batch of chroming delivered to the platers this morning. Had to separate the plastic ends from the chrome handles on the seat recliner handles first though.

Finished off pulling the side part of the headlining through - wouldn't want to do that again in a hurry!

Cleaned off grease and old glue from the rear hatch trim ready for painting - you can only buy this part in black and we wanted grey. Really happy with the results and well worth the effort.

Finished off pulling the side part of the headlining through - wouldn't want to do that again in a hurry!

Cleaned off grease and old glue from the rear hatch trim ready for painting - you can only buy this part in black and we wanted grey. Really happy with the results and well worth the effort.

31st July 2013

Pushed the badges onto the tailgate first thing (1 to get them out of the way and 2 to see what they looked like). Finished off the glove box and bolted it to the car but still have some work to do on the lid yet. Connected up the heater cables and the air vents. All working smoothly.

The choke cable was fitted and connected at the dashboard end. Gearbox tunnel insulation in place and top screwed down. Note the gaffer tape around the join between the top and gearbox tunnel. The factory paid particular attention to sealing this area as it is a source of heat ingress into the cabin.

Finally, the last of the chrome was sorted out ready for dropping off in the morning.

The choke cable was fitted and connected at the dashboard end. Gearbox tunnel insulation in place and top screwed down. Note the gaffer tape around the join between the top and gearbox tunnel. The factory paid particular attention to sealing this area as it is a source of heat ingress into the cabin.

Finally, the last of the chrome was sorted out ready for dropping off in the morning.

30th July 2013

Brakes now successfully bled and now ready for road testing. Carb dashpots taken for polishing and inlet manifold for removal of chrome and polishing. This means that we will be ready to fire up the engine.

Part of the trim kit should arrive tomorrow so we'll continue with the interior.

The rear suspension was bolted up in the laden position and the radius arms torqued and wirelocked.

Part of the trim kit should arrive tomorrow so we'll continue with the interior.

The rear suspension was bolted up in the laden position and the radius arms torqued and wirelocked.

29th July 2013

RHD pedals arrived today so it meant we could continue with fitting up and installing the pedal box. With the clutch master stripped and rebuilt with red grease, we then took the vacuum valve apart on the brake cylinder and cleaned and greased that prior to installing the pedal box into the car.

The last picture shows the pedals in the footwell. Note the non standard accelerator pedal - makes for comfortable cruising!

The exhaust was fitted and lined up - just needs viewing from a few feet away for the final adjustments.

Tomorrow we will bleed the brakes and continue with the roof lining side panel installation.

The last picture shows the pedals in the footwell. Note the non standard accelerator pedal - makes for comfortable cruising!

The exhaust was fitted and lined up - just needs viewing from a few feet away for the final adjustments.

Tomorrow we will bleed the brakes and continue with the roof lining side panel installation.

26th July 2013

Exhaust fitted and just needs lining up and tightening up in place. Picked up the last batch of powder coating so the alternator fan and pulley were fitted along with the brackets for the water rail.

25th July 2013

Couldnt face lying on my back again to finish off the roof lining so fitted the new acorn nuts onto the cylinder head studs. Not that difficult you might think but this is a long stud engine and it has been known for the studs to snap when undoing the nuts. I had already loosened off a couple of nuts so was confident the others would undo. As expected, they all undid and were replaced, one at a time and then re-torqued before moving on to the next one. Look so much nicer now.

We then hooked up the compressor to experiment with soda blasting the carbs. Not that successful but we think we know why; not enough gap inside the pipe to create the venturi effect. We'll have another go tomorrow as we have to get the carbs sorted out.

Finally, we got the fuel tank out of storage and began work on that. It is really solid apart from some surface rust on the underneath. The rust was removed and then the underneath of the tank painted in Bonda Prima. This will kill the rust and stop it coming back. We'll paint the tank in hammerite black in due course. The inside has to be chemically cleaned and then coated with POR.

We then hooked up the compressor to experiment with soda blasting the carbs. Not that successful but we think we know why; not enough gap inside the pipe to create the venturi effect. We'll have another go tomorrow as we have to get the carbs sorted out.

Finally, we got the fuel tank out of storage and began work on that. It is really solid apart from some surface rust on the underneath. The rust was removed and then the underneath of the tank painted in Bonda Prima. This will kill the rust and stop it coming back. We'll paint the tank in hammerite black in due course. The inside has to be chemically cleaned and then coated with POR.

24th July 2013

Headlining main panel installed just the side panels to fit. All went well and it looks great. New stainless steel exhaust arrived today so that will be fitted when the car is back on the ramp.

The RHD bottle bracket was bolted in place and the new rocker box cover washers and acorn chrome nuts fitted.

Glove box coming back together now and will be fitted tomorrow.

The RHD bottle bracket was bolted in place and the new rocker box cover washers and acorn chrome nuts fitted.

Glove box coming back together now and will be fitted tomorrow.

23rd July 2013

Test drove the 120 this morning. What a stunning car! Then back to the workshop to inspect it on the ramp. No major faults found so the customer was happy but it will be coming back later in the year for a service.

Carried on checking the wiring installation and finishing off the little bits. Only a small amount of work to do to complete the job then time to connect the battery.

Started work on the glovebox - transferring the controls from the original. We'll fit that tomorrow.

Finally, prepared the car for the fitting of the roof lining. Really excited about that as it marks the start of the trimming phase. Fingers crossed it all goes well tomorrow.

Carried on checking the wiring installation and finishing off the little bits. Only a small amount of work to do to complete the job then time to connect the battery.

Started work on the glovebox - transferring the controls from the original. We'll fit that tomorrow.

Finally, prepared the car for the fitting of the roof lining. Really excited about that as it marks the start of the trimming phase. Fingers crossed it all goes well tomorrow.

22nd July 2013

The new dash panels arrived today so a big thanks to the boys at Hutsons. Got the RHS side built and installed. Cylinder head painted and looking much better now - still needs another coat but definately getting there.

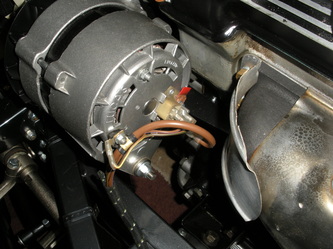

New re-conditioned alternator fitted and the fan and pulley taken for powder coating. Tailgate lock mechanism fitted and all working smoothly (just awaiting the fitting of the tailgate now!).

The speedo cable and mechanical oil pressure gauge were connected. Progress, progress......

The yellow OTS was put on to the ramp and for the first time we were able to get underneath it. Absolutely solid and straight! Unbelievable condition structurally.

New re-conditioned alternator fitted and the fan and pulley taken for powder coating. Tailgate lock mechanism fitted and all working smoothly (just awaiting the fitting of the tailgate now!).

The speedo cable and mechanical oil pressure gauge were connected. Progress, progress......

The yellow OTS was put on to the ramp and for the first time we were able to get underneath it. Absolutely solid and straight! Unbelievable condition structurally.

19th July 2013

Rear bumper now finally in place and it looks great! The holes for the roof aerial were drilled and the bracket screwed in place. Now we can fit the roof lining.

Off to cool off with a large G&T!

Off to cool off with a large G&T!

18th July 2013

The new (used) mechanical oil pressure guage arrived today so that was stripped and the original bezel fitted. Just need to sort out the adaptor at the engine end now! Earth leads and battery lead bolted in place and the underneath was scraped clean and undersealed.

The LHS splash guard shield was fitted - as it is original it fits perfectly. Unfortunately we need a replacement for the RHS. Finally, the original style rear bumper rubber was removed (really spoils the look of the rear in my view as it is too thick) and replaced with the earlier, thinner type. Tomorrow we'll finish off the fit of the bumper and clean the shell.

The LHS splash guard shield was fitted - as it is original it fits perfectly. Unfortunately we need a replacement for the RHS. Finally, the original style rear bumper rubber was removed (really spoils the look of the rear in my view as it is too thick) and replaced with the earlier, thinner type. Tomorrow we'll finish off the fit of the bumper and clean the shell.

16th July 2013

Back on to the E Type, fitted the slave cylinder, wired in the new hi torque starter motor, scraped off the old underseal and chased up a delivery. Not a particularly productive afternoon but it was really hot in the workshop!

15th July 2013

Steering wheel put in place after bolting up the steering column. Looks great with the restored and revarnished wood. The new owner cleaned up the aluminium and it looks great in place. Just goes to show what you can do with a seemingly unrestorable item!

The torsion bar reaction plate was bolted up finally and the radiator hoses fitted and clamped. Attention turned to the triple carb set up as these will be rebuilt. Stripping them down took some time but they are in their component parts now. The new inlet manifold was laid in place as we had to confirm that the thermostat extension lined up with the corresponding hoses from the top of the radiator.

The torsion bar reaction plate was bolted up finally and the radiator hoses fitted and clamped. Attention turned to the triple carb set up as these will be rebuilt. Stripping them down took some time but they are in their component parts now. The new inlet manifold was laid in place as we had to confirm that the thermostat extension lined up with the corresponding hoses from the top of the radiator.

12th July 2013

Lots of jobs completed today; propshaft bolted to gearbox, breather pipe fitted and connected to gearbox, water transfer pipe between bulkhead and water pump laid in place, engine lined up and alternator brackets installed.

Good day and the end of a successful week. Now looking forward to the weekend!

Good day and the end of a successful week. Now looking forward to the weekend!

11th July 2013

Engine finally fitted and bolted (loosely) in place ready for lining up tomorrow, now lots of little jobs to get completed in the engine bay.

Front shock absorbers fitted and front anti roll bar links lined up and loosely fitted. (The front suspension works now the weight of the engine is loading the torsion bars).

Successful day!

Front shock absorbers fitted and front anti roll bar links lined up and loosely fitted. (The front suspension works now the weight of the engine is loading the torsion bars).

Successful day!

10th July 2013

Working with Customers until about 1.30 meant that fitting the engine was delayed somewhat! (Always a pleasure though, chatting to like minded 'E Typers

At last it was time to put the engine in. After much jiggling about (mainly trying to get the lift up high enough to clear the engine and trolley. Once this was achieved, it was a simple task to lower the car down.

Tomorrow will see it all bolted up with the ancillaries fitted.

Picked up some more powder coating today. The cooling fans relay bracket, gearbox breather and spare wheel hold down. Progress!

At last it was time to put the engine in. After much jiggling about (mainly trying to get the lift up high enough to clear the engine and trolley. Once this was achieved, it was a simple task to lower the car down.

Tomorrow will see it all bolted up with the ancillaries fitted.

Picked up some more powder coating today. The cooling fans relay bracket, gearbox breather and spare wheel hold down. Progress!

9th July 2013

Bonnet wiring loom plug stripped and ready for soldering to the new loom. Engine compression test now complete and all cylinders over 120 so we're good to go!

Tomorrows update should be interesting as we will hopefully have some shots of the engine fitted.

Tomorrows update should be interesting as we will hopefully have some shots of the engine fitted.

8th July 2013

Last of the brake lines made up and fitted. Engine bay finished and now ready for the engine to be fitted. Tomorrow we'll complete the engine test and go for fitting the engine. Real progress!

We have relocated the starter motor relay to inside the bulkhead which overcomes the problem with the short loom. We were able to use the original holes in the bulkhead to fit it so that was good news.

Finally, the seats were stripped ready for trimming, chroming and powder coating.

We have relocated the starter motor relay to inside the bulkhead which overcomes the problem with the short loom. We were able to use the original holes in the bulkhead to fit it so that was good news.

Finally, the seats were stripped ready for trimming, chroming and powder coating.

4th July 2013

Finished off the main wiring looms today and now only have the rear to complete. The front brake pads were installed (Green Stuff) so it will stop well.

Otter switch fitted and wired so we will now concentrate on getting the engine fitted in the early part of next week (following successful compression test).

Picked up some more powder coating (sheild brackets) so we can get on with fitting the lower splash shields.

Otter switch fitted and wired so we will now concentrate on getting the engine fitted in the early part of next week (following successful compression test).

Picked up some more powder coating (sheild brackets) so we can get on with fitting the lower splash shields.

3rd July 2013

Work continued on the wiring loom today. Discovered a fault in the wiring diagram this time! Overcame that by using the detailed photographs taken and wiring to the original.

Started strapping in the loom to the frames so the engine bay will be finished tomorrow. Behind the dash completed but just needs tidying now.

Finally, the High Torque starter motor arrived today - look at the difference between the original unit on the left!

Started strapping in the loom to the frames so the engine bay will be finished tomorrow. Behind the dash completed but just needs tidying now.

Finally, the High Torque starter motor arrived today - look at the difference between the original unit on the left!

2nd July 2013

Busy day beginning with a meeting with the Trimmer, Phil. A plan of action has been formulated and the new owner has chosen the interior colour and leather type (light grey). With Phil gone, I returned to the wiring loom and all was going well until I came to wire in one of the bulkhead relays. Wires too short. Despite removing the column and re-routing, still too short by about .5". We can overcome that by repositioning the relay and bracket. Then tried to work out why the washer motor wiring was too long and coming out the opposite side of the bulkhead. It then dawned on me that the loom, in this area, is for a 2+2. Frantic checking of the order revealed that I HAD ordered the correct loom. Need a conversation with the supplier in the morning!

Seats were removed from storage for Phil to look at. Decision made for us to strip them as there is some powder coating and chroming to be done. We'll get them apart later this week.

I took a break from the wiring and started on the centre dash (still waiting for the RHD dash panels to arrive). The centre has to be stripped and then reconfigured for RHD.

With the entire panel stripped down, I re-painted the silver edges around the rocker switches. (Not sure how long the silver will stay on as the original didn't last). The switches were removed and cleaned along with the instruments. We need this panel to finish off the main loom connections tomorrow.

Seats were removed from storage for Phil to look at. Decision made for us to strip them as there is some powder coating and chroming to be done. We'll get them apart later this week.

I took a break from the wiring and started on the centre dash (still waiting for the RHD dash panels to arrive). The centre has to be stripped and then reconfigured for RHD.

With the entire panel stripped down, I re-painted the silver edges around the rocker switches. (Not sure how long the silver will stay on as the original didn't last). The switches were removed and cleaned along with the instruments. We need this panel to finish off the main loom connections tomorrow.

1st July 2013

Began the day by completing the 'first fix' of the rear bumper. All in place but rubber is sitting up more than we'd like so I have left it on the car to see if the rubber settles down.

Trip down to the powder coaters with some trim panels to be blasted clean - we won't powder coat them as it will be too thick for the clips so we'll paint them with hammerite.

Finally, some great news......the wiring loom arrived! At last we can now get on with finishing off the engine compartment ready for engine installation.

Trip down to the powder coaters with some trim panels to be blasted clean - we won't powder coat them as it will be too thick for the clips so we'll paint them with hammerite.

Finally, some great news......the wiring loom arrived! At last we can now get on with finishing off the engine compartment ready for engine installation.

28th June 2013

Lots of work today but little to show for it. The rear gearbox seal and speedo drive seals were changed so no more leaking from the back of the gearbox now.

The new roof lining and sun visors arrived so they were carefully stored away. Work has started on the door internals and the picture shows the window winder mechanism being cleaned and oiled prior to greasing before installation,

The final piece of the cantrail trim was stripped so on Monday we'll get the paperwork raised and off to the powdercoaters.

We didn't move the cars around today as planned - the wiring loom has been shipped so should be here early next week. We'll get that into the engine compartment and fit the engine prior to moving it.

Should see some major milestones reached next week.

The new roof lining and sun visors arrived so they were carefully stored away. Work has started on the door internals and the picture shows the window winder mechanism being cleaned and oiled prior to greasing before installation,

The final piece of the cantrail trim was stripped so on Monday we'll get the paperwork raised and off to the powdercoaters.

We didn't move the cars around today as planned - the wiring loom has been shipped so should be here early next week. We'll get that into the engine compartment and fit the engine prior to moving it.

Should see some major milestones reached next week.

27th June 2013

Gearbox fitted to the engine; a simple thing to do but feels like a major step forward. The plastic sheilds that protect the connectors for the cooling fans has broken off so we made some new ones. (Little details like this that make for a reliable car).

We decided to have a look at the cantrail trims as I was really concerned about these parts. They are made up of a metal plate onto which is glued a shaped piece of foam. This is then covered in vinyl and a chrome trim pressed on top. If the foam has disintegrated, it is difficult to get them remade. Also, the chrome looked to be in very bad condition and again, this is hard to get right. I very carefully stripped them to their major components and was delighted to find that everything is good and can be re-used - just the vinyl had turned to parchment but it protected everything else. The metal will go away for blasting and powdercoating prior to re-trimming. Phew!

The headlining was ordered along with the new sun visors.

We'll get the car off the ramp tomorrow and start preparing the Primrose OTS for its MOT and hopefully future sale.

We decided to have a look at the cantrail trims as I was really concerned about these parts. They are made up of a metal plate onto which is glued a shaped piece of foam. This is then covered in vinyl and a chrome trim pressed on top. If the foam has disintegrated, it is difficult to get them remade. Also, the chrome looked to be in very bad condition and again, this is hard to get right. I very carefully stripped them to their major components and was delighted to find that everything is good and can be re-used - just the vinyl had turned to parchment but it protected everything else. The metal will go away for blasting and powdercoating prior to re-trimming. Phew!

The headlining was ordered along with the new sun visors.

We'll get the car off the ramp tomorrow and start preparing the Primrose OTS for its MOT and hopefully future sale.

26th June 2013

Busy day again today. Started by heading out to an engine rebuilder to discuss an overheating problem on the XK. Plan put in place and car going back next week. Fingers crossed it can be sorted. Heater cables fitted and connected at the bulkhead end. Bellhousing cleaned and the new seal fitted ready to re-unite the gearbox with the engine later on.

25th June 2013

B I got some time in on the FHC and fitted the new throttle linkage and pedal.

Bulkhead looking good now and will soon be finished.

Bulkhead looking good now and will soon be finished.

24th June 2013

Work beginning to come to an end on the S2 FHC as the wiring loom is now critical in order to move forward. Some good news to report, we have now sold this car! Great news and it will go to a good owner who will look after it. He has decided he wants some sensible upgrades like 123 ignition, triple carbs etc and conversion to RHD. The trimmer is coming over next week to discuss final trim colour.

Meanwhile, work continues on detailing the engine and we now have the cam covers back, powder coated and polished. They look great. The steering wheel was dug out to assess how much restoration needs to be carried out. The wood seems ok so that can be cleaned and polished.

The 4TR regulator bracket was fitted along with the lower bracket for the heater box. Again, until we have the loom........

We have at last started cleaning out the grime from the bellhousing. Yuck!

Finally, this beautiful XK120 came over to visit later today. It suffers from an overheating problem when stuck in traffic despite a lot of money being spent on the engine. Hopefully we can help the owner overcome this annoying problem.

Meanwhile, work continues on detailing the engine and we now have the cam covers back, powder coated and polished. They look great. The steering wheel was dug out to assess how much restoration needs to be carried out. The wood seems ok so that can be cleaned and polished.

The 4TR regulator bracket was fitted along with the lower bracket for the heater box. Again, until we have the loom........

We have at last started cleaning out the grime from the bellhousing. Yuck!

Finally, this beautiful XK120 came over to visit later today. It suffers from an overheating problem when stuck in traffic despite a lot of money being spent on the engine. Hopefully we can help the owner overcome this annoying problem.

21st June 2013

Exhaust shield cleaned and polished and batch of powder coating collected. Before and after pictures interesting!

Rear bumper waxoyled prior to fitting and is now in place but just needs bolting down properly. Thats a job for next week. The clutch flexible pipe bracket was put in position.

Heater valve hose pipe fitted - so good to be working with new parts!

Finally, the exhaust manifolds were cleaned and then painted black and placed on the engine block.

Rear bumper waxoyled prior to fitting and is now in place but just needs bolting down properly. Thats a job for next week. The clutch flexible pipe bracket was put in position.

Heater valve hose pipe fitted - so good to be working with new parts!

Finally, the exhaust manifolds were cleaned and then painted black and placed on the engine block.

20th June 2013

Picked up the exhaust manifolds from Kovacs and Son - they had removed the broken studs for us so we'll get them sorted out tomorrow.

19th June 2013

Built the rear bumper up as it has to be fitted to the car as a single unit. Looks fantastic! Couldn't bolt it to the car as it is a 2 handed job and I don't want to damage the paintwork. The radiator shield was bolted in place on the front of the car - important item as it protects the radiator from stone damage and helps direct the airflow when on the move.

The heater box hoses were fitted and the top radiator hose put in place.

Finally, the pedal box was laid in place following restoration in order to get the brake line routing sorted out. The brake pedals were also sent off for converting to RHD.

We must get the rear bumper fitted and brake pipes made and installed before Monday. Going to be tight!

The heater box hoses were fitted and the top radiator hose put in place.

Finally, the pedal box was laid in place following restoration in order to get the brake line routing sorted out. The brake pedals were also sent off for converting to RHD.

We must get the rear bumper fitted and brake pipes made and installed before Monday. Going to be tight!

18th June 2013

Not a lot done in the workshop today as I took the E Type down to Kent to appraise a car. 2 hours on the motorway bought back how good these cars really are. Keeping up with modern traffic and coping with long jams easily. The last long(ish) trip we went on was down to Prescott a couple of weeks ago and it hasn't been touched since.

Got home and found the radiator mounts had arrived so fitted the rad and cooling fans. Stepping back and looking at the installation, I realised how much work has gone into the rebuild of these components.

Finally screwed the new exhaust nuts onto the studs in anticipation of the exhaust manifolds being returned later this week ( some of the stud had snapped off so they had to be professionally removed).

Tomorrow will see the plumbing in of the brake hydraulics.....

Got home and found the radiator mounts had arrived so fitted the rad and cooling fans. Stepping back and looking at the installation, I realised how much work has gone into the rebuild of these components.

Finally screwed the new exhaust nuts onto the studs in anticipation of the exhaust manifolds being returned later this week ( some of the stud had snapped off so they had to be professionally removed).

Tomorrow will see the plumbing in of the brake hydraulics.....

17th June 2013

Lots of little jobs done today, very busy as I'm off down to darkest Kent to appraise a car for a potential buyer in the morning. Radiator assembled but not fitted to car as we are waiting for the new rubber mountings to be delivered. The rear windows were polished and the chrome found not to be in too bad condition. We don't want to rechrome these parts as getting them stripped down could damage the glass and frame.

The pedal box was stripped down and the pedals will be sent off to Hutsons for cranking over to the RHS (they have original sets from af RHD car so use these as a template to ensure accuracy).

The pedal box was stripped down and the pedals will be sent off to Hutsons for cranking over to the RHS (they have original sets from af RHD car so use these as a template to ensure accuracy).

14th June 2013

,Dug the radiator out of storage and stripped it ready for painting. A few coats of Hammerite later and it looks like new again. While the paint was out, we put a few coats on the propshaft - shame it won't be seen!

13th June 2013

Andy at Hutsons sent me down some of the pack required to convert to RHD - Steering Column Cowl, Blanking Plate and Reservoir Bottle bracket so Iwe were able to connect the steering rack to the column and fit the fibreglass cowl to the bulkhead. The new blanking plate and reservoir bottle bracket were bolted into position and the Reservoir fitted.

A trip to the Powder Coaters for what must be the final batch! These included the cam covers so looking forward to getting those back. The front brake pipe union tee piece was cleaned up in preparation for the new pipes (collect pipe flaring tool tomorrow so we can get the hydraulics (brakes) plumbed in).

Finally, couldn't resist offering up a rear bumper quarter. Looks great doesn't it? Might have to fit it properly very soon!

A trip to the Powder Coaters for what must be the final batch! These included the cam covers so looking forward to getting those back. The front brake pipe union tee piece was cleaned up in preparation for the new pipes (collect pipe flaring tool tomorrow so we can get the hydraulics (brakes) plumbed in).

Finally, couldn't resist offering up a rear bumper quarter. Looks great doesn't it? Might have to fit it properly very soon!

12th June 2013

New rack fitted today along with 'fail safes' on both steering rack mountings. Inspected the steering column and bolted it onto the RHS bulkhead. All fits ok so that is good news. Cleaned up some of the dash components - always a satisfactory job as the results are instant and gratifying.

The 4TR voltage regulator and bracket was refurbed using a new mounting (note this took a lot of effort to get it bent to the correct shape. The coil and ballast resistor were fitted (these will be replaced as aesthetically they let the rest of the car down).

The washer pipes were finished off and connected to the motor. We also cleaned up some of the earth contacts on the bulkhead - this will prove beneficial when we install the wiring loom and start chasing faults. Talking of the wiring loom, I called the supplier today who told me that we have another 2 weeks to wait before it ships. We'll have to modify the build schedule a little bit.

The 4TR voltage regulator and bracket was refurbed using a new mounting (note this took a lot of effort to get it bent to the correct shape. The coil and ballast resistor were fitted (these will be replaced as aesthetically they let the rest of the car down).

The washer pipes were finished off and connected to the motor. We also cleaned up some of the earth contacts on the bulkhead - this will prove beneficial when we install the wiring loom and start chasing faults. Talking of the wiring loom, I called the supplier today who told me that we have another 2 weeks to wait before it ships. We'll have to modify the build schedule a little bit.

11th June 2013

Wiper rack cleaned, lubricated and fitted. Wiper motor fitted and converted to RHD (MUCH easier to do than a Series 1 motor!).

Mudguard rubbers riveted in place - so much easier to do when you have factory shields and retaining strips to use. The bonnet locks were installed (to cheer us up really! All this riveting and rummaging around in the bulkhead was getting tedious!).

The steering column support bracket was moved to the RHS of the bulkhead and the cam covers removed ready for refurbishment.

The new steering rack arrived today so that will get fitted in the morning - thanks to Andy at Hutsons for the speedy response despite being up to his eyes in it!

Mudguard rubbers riveted in place - so much easier to do when you have factory shields and retaining strips to use. The bonnet locks were installed (to cheer us up really! All this riveting and rummaging around in the bulkhead was getting tedious!).

The steering column support bracket was moved to the RHS of the bulkhead and the cam covers removed ready for refurbishment.

The new steering rack arrived today so that will get fitted in the morning - thanks to Andy at Hutsons for the speedy response despite being up to his eyes in it!

10th June 2013 - A Riveting Day!

Spent most of the day fitting up the bulkhead pipes - 2 vacuum and 3 water transfer. As this was originally a LHD car, the bulkhead was never drilled by the factory properly for the second vacuum pipe. This took about an hour of careful lining up and drilling to ensure it fitted properly and didn't damage the bulkhead.

Fitted the final clip for the fuel pipe to the bulkhead and connected the pipe to the filter. With the bulkhead transfer pipes installed, we could fit the heater valve. Bulkhead starting to fill up and tomorrow will see the wiper rack going in.and the RHS rear quarter light rubber carrier riveted in position. We will also get the mudguard rubbers in place as a minimum.

Just waiting a delivery date for the new brake pipe flaring tool and wiring loom - thats when the fun really starts!

Finally, have a look at the 'E Type Life Page'. I have uploaded Part II of the trip to Spa last year - makes good reading as I didn't write it!

Fitted the final clip for the fuel pipe to the bulkhead and connected the pipe to the filter. With the bulkhead transfer pipes installed, we could fit the heater valve. Bulkhead starting to fill up and tomorrow will see the wiper rack going in.and the RHS rear quarter light rubber carrier riveted in position. We will also get the mudguard rubbers in place as a minimum.

Just waiting a delivery date for the new brake pipe flaring tool and wiring loom - thats when the fun really starts!

Finally, have a look at the 'E Type Life Page'. I have uploaded Part II of the trip to Spa last year - makes good reading as I didn't write it!

7th June 2013

Decided not to tackle the gearbox today - couldn't face the carbon soaked grease. Instead, the horns were dug out of the boxes, tested, cleaned and repainted. The clips were fitted to the fuel line, brake light tee junction refurbed and installed and finally, the rubber carrier for the rear windows riveted in place. (Note that they are sitting on a bed of dum dum to ensure they seal correctly.

Most of the day was spent bolting up the engine, picture and radiator support frames.

Looking forward to the JDC International E Type Register Day at Prescott on Sunday. Good to catch up with old friends.

Most of the day was spent bolting up the engine, picture and radiator support frames.

Looking forward to the JDC International E Type Register Day at Prescott on Sunday. Good to catch up with old friends.

6th June 2013

Bolted up the radius arms, built the cooling fans onto the frame, fitted the LHS and RHS mudguards, handbrake assembly and the heater box. All go today!

Gave up on the water pipes as the stainless steel ones I have are too hard to drill. We'll make a start on the removing the gearbox bell housing and replace the seal tomorrow. Going to get dirty!

Gave up on the water pipes as the stainless steel ones I have are too hard to drill. We'll make a start on the removing the gearbox bell housing and replace the seal tomorrow. Going to get dirty!

5th June 2013

The FHC is on its' wheels properly now and is ready to move off the ramp. As the car is going to converted to RHD, we are waiting for the new steering rack to arrive before we move it. The vacuum pipes were fitted into the bulkhead and riveted in place. The washer jets and pipework were also fitted. Glad that bits done!

Took a few breaks from the bulkhead assembly to put the fans together now that we have the correct mountings. Also assembled the new UJ onto the steering column.

Wiring looms ordered along with new fuse boxes. Tomorrow should see the bulkhead finished and the radius arms properly attached at the rear.

4th June 2013

Day out today to pick up the rear hatch and doors. It was also a chance to talk to the painters about the bonnet. This has now been stripped back to bare metal, the US Spec side repeaters removed,the holes welded and a small patch of rust on the underneath to cut out.

Back at the workshop, the other torsion bar is fitted and the car ready to sit on its own suspension again. Tomorrow we'll get the car off the ramp.

Back at the workshop, the other torsion bar is fitted and the car ready to sit on its own suspension again. Tomorrow we'll get the car off the ramp.

3rd June 2013

Busy day today, started off by picking up the Works Hack from the barn only to find it wouldnt start (flat battery). One jump start later and we were off back to the workshop. Have to find some time to prepare her for the E Type Day on Sunday at the Prescott Hill Climb.

Work continued on the FHC and we now have the back axle fully built (tie plate in place and anti roll bar). The LHS torsion bar is fitted after taking about 30 minutes or so to clean off the splines so everything slid together and apart easily.

Tomorrow should see the other side fitted and the car rolled off the ramp and moved into the 'clean' part of the workshop for wiring and internal bulkhead assembly.

Work continued on the FHC and we now have the back axle fully built (tie plate in place and anti roll bar). The LHS torsion bar is fitted after taking about 30 minutes or so to clean off the splines so everything slid together and apart easily.

Tomorrow should see the other side fitted and the car rolled off the ramp and moved into the 'clean' part of the workshop for wiring and internal bulkhead assembly.

31st May 2013

Pictures below show the steering arm cleaned and ready for painting. The last shot is of the splined ends of the torsion bars. Vital that these are clean along with the sockets in order to ensure that they fit together easily. This pays dividends later on when setting the suspension.

Next week we will concentrate on getting the car rolling and steering.

Next week we will concentrate on getting the car rolling and steering.

29th May 2013

With the back axle in place, it was time to look at the propshaft. Both UJs had some wear so we are replacing both of them. The shaft will be painted in hammerite black when all the surface rust is cleaned off.

With that complete, all the splines on the steering and torsion bars need to be cleaned for ease of assembly/dis-assembly. Final picture is of the lower steering UJ, this needs replacing as a matter of course.

With that complete, all the splines on the steering and torsion bars need to be cleaned for ease of assembly/dis-assembly. Final picture is of the lower steering UJ, this needs replacing as a matter of course.

23rd May 2013

Rear axle fitted and bolted into place. Some detailed shots of mountings and of the rear suspension. The radius arms are in place and will be tightened up when we have the weight on the axle (this ensures that the rubber takes the correct 'set').

That's another major milestone met and it wont be long before we start on the rewiring stage.

That's another major milestone met and it wont be long before we start on the rewiring stage.

22nd May 2013

The first picture shows the original handbrake cable grommet and the new. Shows how the rubber ages even without exposure to sunlight. It was also time to get the brake flaring kit out as we need to make a pipe for the rear axle. Note that we use a copper alloy pipe (won't rust) with brass connections.

The newly painted fuel pipe connecting the main pipe to the fuel filter was fitted along with the anti roll bar links.

Tomorrow will see the rear axle fitted (if I can get the pipe made - had a disaster with the flaring tool!). Fingers crossed.

The newly painted fuel pipe connecting the main pipe to the fuel filter was fitted along with the anti roll bar links.

Tomorrow will see the rear axle fitted (if I can get the pipe made - had a disaster with the flaring tool!). Fingers crossed.

21st May 2013

Picked up the bumpers and handbrake from the chromers today. Really great job (except they hadn't filled in the holes on the over riders for the AMCO bars). Oh well, they will go back in the morning.

Built the handbrake assembly and checked it still worked ok! Finally, fitted the tee piece for the rear brake and realised I can't re-use the original brake pipes - that means I'll have to get two made tomorrow......

Built the handbrake assembly and checked it still worked ok! Finally, fitted the tee piece for the rear brake and realised I can't re-use the original brake pipes - that means I'll have to get two made tomorrow......

20th May 2013

Collected some powder coating today which meant we could focus on the front brakes. These are now installed with new discs and the new calipers that came with the car.

The final suspension photo shows the suspension setting links in place ready to set up the torsion bars.

The final suspension photo shows the suspension setting links in place ready to set up the torsion bars.

17 May 2013

Started to strip the front hubs down today. Picked up the latest batch of nickel plating and fitted the nuts and washers. Front suspension looks much better now.

Fitted a new strap to the washer bottle bracket and bolted it to the bulkhead. Coming together now!

Fitted a new strap to the washer bottle bracket and bolted it to the bulkhead. Coming together now!

16th May 2013

Work carries on apace with the FHC. First photograph shows how many washers and nuts required just to attach the cooling fans to the cowl! (We will be using the shiny ones only). They can't be assembled as we are still waiting for the rubber mountings to be delivered.

Radius arms with drop links for rear anti roll bar ready for fitting.

Finally completed the build of the rear cage - still no sign of the missing shock absorber spacer so looks like I'll be ordering a new one in the morning.

The RHS stub axle was put in place and we should have the car back on its wheels next week.

Radius arms with drop links for rear anti roll bar ready for fitting.

Finally completed the build of the rear cage - still no sign of the missing shock absorber spacer so looks like I'll be ordering a new one in the morning.

The RHS stub axle was put in place and we should have the car back on its wheels next week.

15th May 2013

No update yesterday as it was spent with an old mate for a few hours then sorting out the paperwork for a car just sold, speaking to a customer about getting their car in at the weekend so by the time that was all done, the day had gone!