1964 White Series 1 OTS.

Brief for this car is a total restoration with some minor upgrades.

Brief for this car is a total restoration with some minor upgrades.

9th February 2018

The car is now finished and the rear axle is fitted. There were a few wiring issues and they have been addressed (traced it down to a faulty fuse).

The car is now finished and the rear axle is fitted. There were a few wiring issues and they have been addressed (traced it down to a faulty fuse).

2nd February 2018

We had to have the car back for some warranty work. After 1500 miles, the diff sounded noisy so we stripped it out and took it over to Alan at AJS Engineering. We had to replace the CWP with a new 3.07 unit so with new seals and bearings, it should be good to go.

We had to have the car back for some warranty work. After 1500 miles, the diff sounded noisy so we stripped it out and took it over to Alan at AJS Engineering. We had to replace the CWP with a new 3.07 unit so with new seals and bearings, it should be good to go.

23rd December 2016

Looking absolutely stunning!

Looking absolutely stunning!

16th December 2016

Finally, the car was handed over to the customer for safekeeping over the winter. We will have it back in the Spring for final commissioning.

Finally, the car was handed over to the customer for safekeeping over the winter. We will have it back in the Spring for final commissioning.

9th December 2016

The crew turned up to photograph the car and after hours of adjusting light, positioning and clicking, the photos should be ready next week. Really excited to see how they turn out.

The crew turned up to photograph the car and after hours of adjusting light, positioning and clicking, the photos should be ready next week. Really excited to see how they turn out.

2nd December 2016

Jamie from Detailers came in today to detail the Grey S1 OTS (SB) in preparation for a professional photoshoot next week. Looks absolutely stunning!

Jamie from Detailers came in today to detail the Grey S1 OTS (SB) in preparation for a professional photoshoot next week. Looks absolutely stunning!

11th November 2016

The blanking plate turned up for the radio console so after trimming, it was fitted.

The blanking plate turned up for the radio console so after trimming, it was fitted.

4th November 2016

The radio console is built and trimmed, just missing the blanking plate to be fitted prior to going into the car. The chrome headlight rings are on now we have shimmed the headlight scoops.

The radio console is built and trimmed, just missing the blanking plate to be fitted prior to going into the car. The chrome headlight rings are on now we have shimmed the headlight scoops.

19th October 2016

Finally now passed the MOT with zero advisories. Starts and runs well. Now we have to put some miles on her when the weather is good!

Finally now passed the MOT with zero advisories. Starts and runs well. Now we have to put some miles on her when the weather is good!

15th October 2016

The car is now running but we have a fuel leak from the union in the boot that connects the carbs to the fuel pump. Turns out that the new pipe joint isn't compatible with the original! We'll have to lap the new one in in order to achieve a proper seal.

The car is now running but we have a fuel leak from the union in the boot that connects the carbs to the fuel pump. Turns out that the new pipe joint isn't compatible with the original! We'll have to lap the new one in in order to achieve a proper seal.

September 2016

Trim now complete.

Trim now complete.

5th August 2016

Final straight now and the bonnet chromes, headlights, horns, bonnet wiring, bonnet plug and socket are all fitted up. The safety catch is in along with the grille. The new tacho generator is in place and the bumpers will be fitted up along with the scoops and headlight chromes next week.

Final straight now and the bonnet chromes, headlights, horns, bonnet wiring, bonnet plug and socket are all fitted up. The safety catch is in along with the grille. The new tacho generator is in place and the bumpers will be fitted up along with the scoops and headlight chromes next week.

22nd July 2016

Back from the trimmers having had the hood fitted. Looks great!

Back from the trimmers having had the hood fitted. Looks great!

27th May 2016.

Car loaded and waiting to go up to MCT trimming for hood fitting.

Car loaded and waiting to go up to MCT trimming for hood fitting.

22nd May 2016

Having 2 Series 1 OTS cars in the same colour can be confusing! We now have the wipers fitted, doors built up and the bonnet hinge dampers all fitted. It will be off to Mick Turley at MCT later this week for the hood to be fitted.

Having 2 Series 1 OTS cars in the same colour can be confusing! We now have the wipers fitted, doors built up and the bonnet hinge dampers all fitted. It will be off to Mick Turley at MCT later this week for the hood to be fitted.

13th May 2016

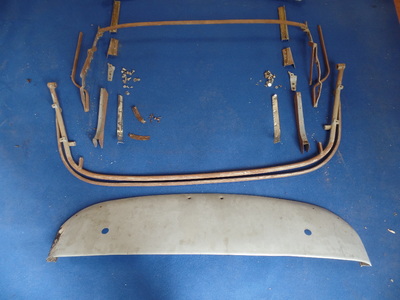

The Hood frame has been stripped ready for the trimmers next week and will be blasted and painted in the correct colour. We now have the wheel arches trimmed in the correct mocquette material.

The Hood frame has been stripped ready for the trimmers next week and will be blasted and painted in the correct colour. We now have the wheel arches trimmed in the correct mocquette material.

10th May 2016

We now have the new screen fitted and the upper and lower chromes. Next week (fingers crossed) it will be delivered to Mick Turley for hood fitting.

We now have the new screen fitted and the upper and lower chromes. Next week (fingers crossed) it will be delivered to Mick Turley for hood fitting.

27th April 2016

The car is now back with us with the newly fitted doors, bonnet and bootlid. Looks stunning!

The car is now back with us with the newly fitted doors, bonnet and bootlid. Looks stunning!

22nd April 2016

The paintshop told me the car was ready for collection so we loaded up the trailer and hot footed it over there only to find that they had discovered a dent in the bonnet. A few quick photos later and we returned sans car.

The paintshop told me the car was ready for collection so we loaded up the trailer and hot footed it over there only to find that they had discovered a dent in the bonnet. A few quick photos later and we returned sans car.

1st April 2016

The bonnet is now fitted and we will reveal the final photos of the car with the doors, bonnet and bootlid finally in place next week.

The bonnet is now fitted and we will reveal the final photos of the car with the doors, bonnet and bootlid finally in place next week.

27th March 2016

The Grey S1 OTS now has the doors and bootlid fitted. Just the locks to install and the bonnet and we will get her back again for finishing.

The Grey S1 OTS now has the doors and bootlid fitted. Just the locks to install and the bonnet and we will get her back again for finishing.

20th March 2016

The car is now back in the paintshop for bonnet, doors and bootlid fit up. Looked lovely in the sunshine.

The car is now back in the paintshop for bonnet, doors and bootlid fit up. Looked lovely in the sunshine.

16th March 2016

The car is now ready to go over to the Paint Shop to have the doors, bootlid and bonnet finally fitted. Picture shows the rubbers glued into position and held in with tape.

The car is now ready to go over to the Paint Shop to have the doors, bootlid and bonnet finally fitted. Picture shows the rubbers glued into position and held in with tape.

12th March 2016

We are fitting a mechanical brake light switch so had a batch made.

We had the pedals cranked but weren't happy with the angles so we spent a happy 2 hours in the Blacksmith shop re-bending them. Really pleased with the result now!

We are fitting a mechanical brake light switch so had a batch made.

We had the pedals cranked but weren't happy with the angles so we spent a happy 2 hours in the Blacksmith shop re-bending them. Really pleased with the result now!

9th March 2016

Exhaust fitted at last and started the suspension tigthtening. First picture shows the manifold to exhaust nuts with the Nordlock washers in place. Making a big bore exhaust for an E Type is really difficult as there isn't a lot of room to run 2 big pipes where it goes round the corner over the torsion bar reaction plate. Our job is to get it as high as possible onto the car and make sure everything is level and lined up. Picked up the oil filter canister from the powder coaters so that will get fitted in the morning. The boot lock is fitted and working. We can't tighten it up yet as the paint shop need to set the lock up when the boot lid is on. The distributor has been sent out to the Distributor Doctor for refurbishing and fitting with electronic ignition. You can see how dusty components get hanging around a clean workshop. I think we ought to give her a bit of a clean and take some more shots later on!

Exhaust fitted at last and started the suspension tigthtening. First picture shows the manifold to exhaust nuts with the Nordlock washers in place. Making a big bore exhaust for an E Type is really difficult as there isn't a lot of room to run 2 big pipes where it goes round the corner over the torsion bar reaction plate. Our job is to get it as high as possible onto the car and make sure everything is level and lined up. Picked up the oil filter canister from the powder coaters so that will get fitted in the morning. The boot lock is fitted and working. We can't tighten it up yet as the paint shop need to set the lock up when the boot lid is on. The distributor has been sent out to the Distributor Doctor for refurbishing and fitting with electronic ignition. You can see how dusty components get hanging around a clean workshop. I think we ought to give her a bit of a clean and take some more shots later on!

7th March 2016

The car is coming together nicely now and the carbs are finally fitted. Really fills up that area nicely. The exhaust would have been fitted but we have a problem with the hole centres on the mounting flange to the manifold. It has gone back to the manufacturers for rectification.

The car is coming together nicely now and the carbs are finally fitted. Really fills up that area nicely. The exhaust would have been fitted but we have a problem with the hole centres on the mounting flange to the manifold. It has gone back to the manufacturers for rectification.

25th February 2016

Original spinners out for chrome plating and re-dressing.

Original spinners out for chrome plating and re-dressing.

22nd February 2016

More work has been completed with the rear anti roll bar links connected and work started on fitting the new exhaust. We had to call a halt to that so fitted the new rear wheels instead. (The spinners are the originals that we are having re-chromed).

More work has been completed with the rear anti roll bar links connected and work started on fitting the new exhaust. We had to call a halt to that so fitted the new rear wheels instead. (The spinners are the originals that we are having re-chromed).

16th February 2016

The boot area is coming together well. The fuel tank is in position and the new (Hardy) fuel pump is fitted. The new wheels arrived and look fantastic (5.5 inch rims with 185 tyres). We were concerned that the 5.5 wheel wouldn't fit in the spare wheel well. As can be seen, it does. The replacement, rear, exhaust manifold arrived but we will have to buy a matching front one as the new type are thicker than the originals so the mounting studs won't match.

The boot area is coming together well. The fuel tank is in position and the new (Hardy) fuel pump is fitted. The new wheels arrived and look fantastic (5.5 inch rims with 185 tyres). We were concerned that the 5.5 wheel wouldn't fit in the spare wheel well. As can be seen, it does. The replacement, rear, exhaust manifold arrived but we will have to buy a matching front one as the new type are thicker than the originals so the mounting studs won't match.

6th February 2016

The build continues (we have been updating the page directly) and we had a special tool made to help remove the lower gearstick bush. With this now pressed out, a new one was fitted along with the correct washers. A new gear stick was fitted as it was more cost effective than having the original re-chromed.

The build continues (we have been updating the page directly) and we had a special tool made to help remove the lower gearstick bush. With this now pressed out, a new one was fitted along with the correct washers. A new gear stick was fitted as it was more cost effective than having the original re-chromed.

31st January 2016

Gear lever mechanism stripped down ready for new bushes and washers. Number plate lights, petrol tank and fuel line now clipped in place. Lower hoses fitted and clutch slave cylinder.

Gear lever mechanism stripped down ready for new bushes and washers. Number plate lights, petrol tank and fuel line now clipped in place. Lower hoses fitted and clutch slave cylinder.

10th January 2016

More work completed with the brake lines plumbed in, the lower exhaust sheilds fitted, LH rear bumper, drain pipes for the boot and the new Dynator in place.

More work completed with the brake lines plumbed in, the lower exhaust sheilds fitted, LH rear bumper, drain pipes for the boot and the new Dynator in place.

21st December 2015

The engine is now back in - all went in easily with no damage to the engine frames or bulkhead (not difficult, just wonder some times how other people manage to cause the damage they do judging by some of the ham fisted engine removal/installations we have seen!).

The engine is now back in - all went in easily with no damage to the engine frames or bulkhead (not difficult, just wonder some times how other people manage to cause the damage they do judging by some of the ham fisted engine removal/installations we have seen!).

12th December 2015

Steering column connected, more wiring completed. Just brake lines to make up and ready for engine installation.

Steering column connected, more wiring completed. Just brake lines to make up and ready for engine installation.

10th December 2015

Pedal box fitted and it is now on its' wheels for the first time in over a year. Big moment!

Pedal box fitted and it is now on its' wheels for the first time in over a year. Big moment!

1st December 2015

The Grey S1 OTS now has the radius arms fitted and finally, the pedal box. The radiator and bracketry is trial fitted as I need the sealing foam to fit in between the radiator and cowl.

The Grey S1 OTS now has the radius arms fitted and finally, the pedal box. The radiator and bracketry is trial fitted as I need the sealing foam to fit in between the radiator and cowl.

26th November 2015

We now have the RHS rear light fitted, the rack bolted down properly and the bonnet pull clips in place. Waiting for the brackets for the header tank to arrive for powder coating before we can fit the new radiator.

We now have the RHS rear light fitted, the rack bolted down properly and the bonnet pull clips in place. Waiting for the brackets for the header tank to arrive for powder coating before we can fit the new radiator.

24th November 2015

More work completed with the fan relay fitted and some other wiring installed.

More work completed with the fan relay fitted and some other wiring installed.

21st November 2015

Work progresses and we now have the new vented disc kit fitted, new front wheel bearings, handbrake, upgraded alu header tank and copy of the Marston Radiator ready to be fitted.

Work progresses and we now have the new vented disc kit fitted, new front wheel bearings, handbrake, upgraded alu header tank and copy of the Marston Radiator ready to be fitted.

2nd November 2015

More work complete and the heater flaps are now fitted with new seals and knobs. The rear axle is bolted in place and the heater box built and installed.

More work complete and the heater flaps are now fitted with new seals and knobs. The rear axle is bolted in place and the heater box built and installed.

23rd October 2015

More parts fitted with the newly plated blanking plates in place, the air filter, glove box, anti roll bar and lower gearbox gaitor fitted.

More parts fitted with the newly plated blanking plates in place, the air filter, glove box, anti roll bar and lower gearbox gaitor fitted.

19th October 2015

More plating taken over to the chromers and the stub axles dropped off for powder coating. Wiring looms in place finally and now need the dashboards in order to complete. Rear axle in place after I called in the 'Big Guns' in the shape of Leon and Murray.

More plating taken over to the chromers and the stub axles dropped off for powder coating. Wiring looms in place finally and now need the dashboards in order to complete. Rear axle in place after I called in the 'Big Guns' in the shape of Leon and Murray.

18th October 2015

I left the workshop camera in the workshop so only have photos of the Gunmetal OTS to show. The rear axle is now fitted and only needs a few more bolts to finish it off. The subframes are in place along with the front suspension. Just the stub axles to restore and then the car is rolling again. Next major job will be the engine and gearbox installation. We want to focus on completing the wiring next.

I left the workshop camera in the workshop so only have photos of the Gunmetal OTS to show. The rear axle is now fitted and only needs a few more bolts to finish it off. The subframes are in place along with the front suspension. Just the stub axles to restore and then the car is rolling again. Next major job will be the engine and gearbox installation. We want to focus on completing the wiring next.

12th October 2015

Progress slowed down a bit over the weekend as I was entertaining the Swedish group from our Forum and then Sunday was the Jaguar spares day at the NAC. We picked up the frames from the paintshop on Friday night so when we have the frame kit (tomorrow) we should be able to bolt them back onto the monocoque.

Progress slowed down a bit over the weekend as I was entertaining the Swedish group from our Forum and then Sunday was the Jaguar spares day at the NAC. We picked up the frames from the paintshop on Friday night so when we have the frame kit (tomorrow) we should be able to bolt them back onto the monocoque.

8th October 2015

More parts fitted and the wiring looms laid to the rear. Final picture is of me moving the wiring around on the Wiper motor in order to convert it for RHD.

More parts fitted and the wiring looms laid to the rear. Final picture is of me moving the wiring around on the Wiper motor in order to convert it for RHD.

6th October 2015

Fit up continues and we have the rear numberplate chrome and reversing light in place. Wiring looms starting to be laid in and lots of other small jobs complete. The photos show the level of detail demanded if this is to be a high end restoration.

Fit up continues and we have the rear numberplate chrome and reversing light in place. Wiring looms starting to be laid in and lots of other small jobs complete. The photos show the level of detail demanded if this is to be a high end restoration.

2nd October 2015

Various parts have now been fitted. We always refit the original chassis plate as we believe this is the heart of the car. The original body number plate was also re-fitted in the boot inner wing. The vacuum tank is in position and note the 'Trico' stencil. All 3.8s had this stencil but it washed off easily leaving no trace. Thanks to David Jones for painting it on for me. The washer jets, washer pipes, blanking plate, washer bottle and motor have all been attached along with those pesky heater transfer pipes in the bulkhead. Must have a shout out to Martin Robey who made the pipes - they really fit well!

Various parts have now been fitted. We always refit the original chassis plate as we believe this is the heart of the car. The original body number plate was also re-fitted in the boot inner wing. The vacuum tank is in position and note the 'Trico' stencil. All 3.8s had this stencil but it washed off easily leaving no trace. Thanks to David Jones for painting it on for me. The washer jets, washer pipes, blanking plate, washer bottle and motor have all been attached along with those pesky heater transfer pipes in the bulkhead. Must have a shout out to Martin Robey who made the pipes - they really fit well!

29th September 2015

Steering column now fully restored with new bushes. The indicator switch has been stripped, cleaned and greased.

Steering column now fully restored with new bushes. The indicator switch has been stripped, cleaned and greased.

28th September 2015

FINALLY! We have collected the bodyshelf from the paintshop. Now looking fantastic in gunmetal grey. The finish looks better in the flesh so, once again, great job from Phil. Excited to be starting this project now.

FINALLY! We have collected the bodyshelf from the paintshop. Now looking fantastic in gunmetal grey. The finish looks better in the flesh so, once again, great job from Phil. Excited to be starting this project now.

15th August 2015

We now have progress on the White OTS. The car is painted and the pictures show the shell with the paint 'out of the gun' ie, not flatted and polished yet. Still looks great!

We now have progress on the White OTS. The car is painted and the pictures show the shell with the paint 'out of the gun' ie, not flatted and polished yet. Still looks great!

8th August 2015

Wiper mechanism all stripped, cleaned, greased and re-assembled ready to be fitted.

Wiper mechanism all stripped, cleaned, greased and re-assembled ready to be fitted.

5th August 2015

The car now has paint applied to the underneath so it is really coming together quickly now. The final rubbing down is nearly complete ready for top coat in the next week. As an aside, the owner of the car arrived in his new everyday car. What a piece of kit! 400BHP of Porsche Carrera S. WOW! Handling and performance is just incredible. If you get a chance to drive one, do it!

The car now has paint applied to the underneath so it is really coming together quickly now. The final rubbing down is nearly complete ready for top coat in the next week. As an aside, the owner of the car arrived in his new everyday car. What a piece of kit! 400BHP of Porsche Carrera S. WOW! Handling and performance is just incredible. If you get a chance to drive one, do it!

27th July 2015

Spent some time refurbishing components. Wiper rack stripped, cleaned, greased and reassembled along with the wiper motor and fuel bowl. Really satisfying doing this kind of work as it isn't too physical!

Spent some time refurbishing components. Wiper rack stripped, cleaned, greased and reassembled along with the wiper motor and fuel bowl. Really satisfying doing this kind of work as it isn't too physical!

20th July 2015

Pictures are of the small bushes that go either side of the steering column mount. Replacing these all helps to get the car feeling tight so well worth the effort. The three cylinders are also from the same car and are going away for lining in stainless steel and rebuilding along with the servo bellows. Essential that the original parts are used wherever possible as some of the repros just don't fit!

Pictures are of the small bushes that go either side of the steering column mount. Replacing these all helps to get the car feeling tight so well worth the effort. The three cylinders are also from the same car and are going away for lining in stainless steel and rebuilding along with the servo bellows. Essential that the original parts are used wherever possible as some of the repros just don't fit!

13th July 2015

The aluminium spacers that sit on the front anti roll bar were cleaned up and ready to fit - amazing what 30minutes with a rotary wire brush can achieve.

The aluminium spacers that sit on the front anti roll bar were cleaned up and ready to fit - amazing what 30minutes with a rotary wire brush can achieve.

8th July 2015

Front suspension, TBR plate, drop links and propshaft. All powder coated, plated and newly bushed ready for installation.

Front suspension, TBR plate, drop links and propshaft. All powder coated, plated and newly bushed ready for installation.

2nd July 2015

The underbonnet panels are now painted in top coat, bonnet re-assembled and refitted onto the car. Looks fantastic. With all the excitement of the newly applied paint, we fitted the new polybush lower suspension mountings into their housings.

The underbonnet panels are now painted in top coat, bonnet re-assembled and refitted onto the car. Looks fantastic. With all the excitement of the newly applied paint, we fitted the new polybush lower suspension mountings into their housings.

29th April 2015

Some more pictures of the White S1 OTS ready for final flatting and primer.

Some more pictures of the White S1 OTS ready for final flatting and primer.

22nd April 2015

Car is now in the final primer stage ready for painting. Not far to go now and the gaps and finish are superb. Customer is very happy which makes it all worthwhile!

Car is now in the final primer stage ready for painting. Not far to go now and the gaps and finish are superb. Customer is very happy which makes it all worthwhile!

13th April 2015

We took a trip over to the Paintshop to check on progress of the White OTS. On the final prep stage now prior to the primer being applied. The gaps are just about there and you can see in photo 6 there is still a little to do on the RHS door leading edge on to A post.

We took a trip over to the Paintshop to check on progress of the White OTS. On the final prep stage now prior to the primer being applied. The gaps are just about there and you can see in photo 6 there is still a little to do on the RHS door leading edge on to A post.

31st March 2015

Pedal box parts back from the powder coaters. We pick up the plated parts later on in the week so we can start to move that forward.

Pedal box parts back from the powder coaters. We pick up the plated parts later on in the week so we can start to move that forward.

26th March 2015

The strip down of the brake servo has begun and the parts are now out for powder coating and plating. Luckily, all the nylon bearings are in good condition so we should be able to rebuild it to as new condition easily.

The strip down of the brake servo has begun and the parts are now out for powder coating and plating. Luckily, all the nylon bearings are in good condition so we should be able to rebuild it to as new condition easily.

13th March 2015

We are now at the filling stage and it shouldn't be long before we will see the Gunmetal Grey being applied. Can't wait!

We are now at the filling stage and it shouldn't be long before we will see the Gunmetal Grey being applied. Can't wait!

10th March 2015

The tub is now 90% complete. Just the trial fit of the front bumpers and headlight chromes to complete. As you can see, the RHS bumper is slightly lower than the LHS so there is still a little bit of fettling to do before we can move on to the next stage.

The tub is now 90% complete. Just the trial fit of the front bumpers and headlight chromes to complete. As you can see, the RHS bumper is slightly lower than the LHS so there is still a little bit of fettling to do before we can move on to the next stage.

23rd February 2015

We are on the finishing straight with regards to the welding. The bonnet is fitted and now needs gapping. The chrome is being trial fitted and any adjustments made to the body or chrome completed so when we are ready to fit them finally, everything should look good.

We are on the finishing straight with regards to the welding. The bonnet is fitted and now needs gapping. The chrome is being trial fitted and any adjustments made to the body or chrome completed so when we are ready to fit them finally, everything should look good.

17th February 2015

Rebuilt engine, carbs and back axle awaiting bodyshell.....

Rebuilt engine, carbs and back axle awaiting bodyshell.....

12th February 2015

We now have the frames fitted and the bonnet is built and ready for fitting and gapping. Next week we will take the chrome over for trial fit. All the welding is complete on the tub so thankfully, that mammoth task is over. The steering column is back from the powder coaters so we have started to re-assemble it with all new parts. We also picked up the engine and rebuilt carbs yesterday. They all look magnificent! It really is a thing of beauty, an E Type engine.

We now have the frames fitted and the bonnet is built and ready for fitting and gapping. Next week we will take the chrome over for trial fit. All the welding is complete on the tub so thankfully, that mammoth task is over. The steering column is back from the powder coaters so we have started to re-assemble it with all new parts. We also picked up the engine and rebuilt carbs yesterday. They all look magnificent! It really is a thing of beauty, an E Type engine.

20th January 2015

Stripping out trim panels ready for powder coating, it was interesting to note that the door cappings had a piece of foam glued to both ends to take up the gap between the door cap and the door shell. Other small, important jobs have also been completed while we wait for the tub to be completed; the Indicator Switch stripped, cleaned and tested, Left and Right dash panels built (with new choke lens and dipswitch) and the steering column stripped. We have to rotate the bracket that holds the indicator switch 180 degrees as part of the RHD conversion.

Stripping out trim panels ready for powder coating, it was interesting to note that the door cappings had a piece of foam glued to both ends to take up the gap between the door cap and the door shell. Other small, important jobs have also been completed while we wait for the tub to be completed; the Indicator Switch stripped, cleaned and tested, Left and Right dash panels built (with new choke lens and dipswitch) and the steering column stripped. We have to rotate the bracket that holds the indicator switch 180 degrees as part of the RHD conversion.

17th January 2015

Met up with the owner today and went over to the paintshop to check on progress. Bodyshell now nearly complete and the next stage will be the gapping to ensure all panels fit correctly. Next week the engine frames should be delivered so we will begin assembling the bonnet.

Met up with the owner today and went over to the paintshop to check on progress. Bodyshell now nearly complete and the next stage will be the gapping to ensure all panels fit correctly. Next week the engine frames should be delivered so we will begin assembling the bonnet.

14th January 2015

Still working through the instrument restoration...

Still working through the instrument restoration...

12th January 2015

Work continues in the background with the fuel tank now powder coated and sealed with POR15. The new capilliary oil pressure guage has been built into the original casing so the instruments will still match

Work continues in the background with the fuel tank now powder coated and sealed with POR15. The new capilliary oil pressure guage has been built into the original casing so the instruments will still match

7th January 2015

Still coming along with both floors now in position. The tub should be completed (hopefully) this week.

Still coming along with both floors now in position. The tub should be completed (hopefully) this week.

22nd December 2014

The fuel tank was picked up from the strippers and delivered to the Powder Coaters. We will seal it with POR 15 when it is finished.

The fuel tank was picked up from the strippers and delivered to the Powder Coaters. We will seal it with POR 15 when it is finished.

17th December 2014

The welding of the White S1 OTS continues apace and it won't be long now before we are ready for gapping.

The welding of the White S1 OTS continues apace and it won't be long now before we are ready for gapping.

15th December 2014

Stripped the instrument panels down. Very dusty but the chrome came up fine. The instrument bezels will be taken off to the powder coaters in the morning. Took a trip over to see the guys in the paintshop. The White S1 OTS is coming together nicely now and one side is complete. The other side is underway so the bodyshell shouldn't be too far away from being complete. We then have the bonnet to build and start the gapping.

Stripped the instrument panels down. Very dusty but the chrome came up fine. The instrument bezels will be taken off to the powder coaters in the morning. Took a trip over to see the guys in the paintshop. The White S1 OTS is coming together nicely now and one side is complete. The other side is underway so the bodyshell shouldn't be too far away from being complete. We then have the bonnet to build and start the gapping.

9th December 2014

The newly built rear axle was delivered today for the white OTS. Completely rebuilt with a new diff ratio of 3.06 - should make for relaxed cruising whilst retaining the original sparkle.

The newly built rear axle was delivered today for the white OTS. Completely rebuilt with a new diff ratio of 3.06 - should make for relaxed cruising whilst retaining the original sparkle.

8th December 2014

Assembled the washer bottle frame today. Just a small thing but very satisfying!

Assembled the washer bottle frame today. Just a small thing but very satisfying!

28th November 2014

Coming along with lots of small panels now in place. Door gaps don't look bad at this stage but they will be tightened up prior to going into primer phase.

Coming along with lots of small panels now in place. Door gaps don't look bad at this stage but they will be tightened up prior to going into primer phase.

20th November 2014

The brake pedal box has been taken apart. Everything looks ok but we will need to strip it further to confirm.

The brake pedal box has been taken apart. Everything looks ok but we will need to strip it further to confirm.

16th October 2014

The panel work continues with attention now being turned to the RHS rear quarter panel. The old one has been cut out and the remaining panels prepared/repaired for the new one to be welded into position.

The panel work continues with attention now being turned to the RHS rear quarter panel. The old one has been cut out and the remaining panels prepared/repaired for the new one to be welded into position.

13th October 2014

Body tub coming along nicely with a lot of the outer panel work complete.

Body tub coming along nicely with a lot of the outer panel work complete.

2nd October 2014

Bonnet is now cleaned off and the under panels etch primed. The new door skin has been fitted so things are moving along nicely.

Bonnet is now cleaned off and the under panels etch primed. The new door skin has been fitted so things are moving along nicely.

15th September 2014

Stripped the bonnet down to its' component parts and is dirty but solid. We will have to deal with the inevitable dents but thankfully, no rot.

Stripped the bonnet down to its' component parts and is dirty but solid. We will have to deal with the inevitable dents but thankfully, no rot.

5th September 2014

Plating collected!

Plating collected!

31st August 2014

More powder coating and plating dropped off. Lower suspension, brackets and mounts mainly. Last shot is of a batch of upper wishbones back from Mike having been machined to accept our nylon upgrade.

More powder coating and plating dropped off. Lower suspension, brackets and mounts mainly. Last shot is of a batch of upper wishbones back from Mike having been machined to accept our nylon upgrade.

13th August 2014

Took 60 odd parts to the powder coaters today. Really good to be getting rid of scruffy looking components from the workshop! Last photo is of the boot lock. Note the washers fitted in between the base and lock mechanism. Not seen that before so need to check if it is correct.

Took 60 odd parts to the powder coaters today. Really good to be getting rid of scruffy looking components from the workshop! Last photo is of the boot lock. Note the washers fitted in between the base and lock mechanism. Not seen that before so need to check if it is correct.

11th August 2014

Now back to bare metal and I am pleased to report that there were no nasty surprises found!

Now back to bare metal and I am pleased to report that there were no nasty surprises found!

30th July 2014

The tub has been blasted and shown up where it has been repaired over the years. This car looked fantastic but we know they are all hiding repairs and rust. This way, we know exactly what needs to be done and it will be documented for the future. Basically, the structure is sound but the sills and bootfloor have been repaired so we will replace them as a matter of course. No real major surprises.

The tub has been blasted and shown up where it has been repaired over the years. This car looked fantastic but we know they are all hiding repairs and rust. This way, we know exactly what needs to be done and it will be documented for the future. Basically, the structure is sound but the sills and bootfloor have been repaired so we will replace them as a matter of course. No real major surprises.

21st July 2014

The car is now fully stripped and over in the paintshop. It should be blasted in the next few days which will allow us to really see how good the structure is. The rear axle is very dusty but looks to have been rebuilt fairly recently (well, cleaned at least). It will still be stripped and rebuilt with a different ratio diff installed. New engine frames are on order and the old ones scrapped. No corrosion detected but they have been badly jacked up underneath and are dented as a result.

Two of the subframe mounts can be seen in the final photo. Note how one has completely separated from the metal. This is why you should never leave the rear suspension on an E Type hanging by lifting the back of the car on the chassis rails!

The car is now fully stripped and over in the paintshop. It should be blasted in the next few days which will allow us to really see how good the structure is. The rear axle is very dusty but looks to have been rebuilt fairly recently (well, cleaned at least). It will still be stripped and rebuilt with a different ratio diff installed. New engine frames are on order and the old ones scrapped. No corrosion detected but they have been badly jacked up underneath and are dented as a result.

Two of the subframe mounts can be seen in the final photo. Note how one has completely separated from the metal. This is why you should never leave the rear suspension on an E Type hanging by lifting the back of the car on the chassis rails!

10th July 2014

Delivered the engine down to VSE for complete refurbishment. This one will be rebuilt to standard specification.

Delivered the engine down to VSE for complete refurbishment. This one will be rebuilt to standard specification.

6th July 2014

Now stripped with only the rear axle to remove.

Now stripped with only the rear axle to remove.

1st July 2014

The strip down continues with speed now and the ancillaries have all been removed. Tomorrow should see the engine and gearbox removed. Thankfully we have help in the shape of Tony all day.

The strip down continues with speed now and the ancillaries have all been removed. Tomorrow should see the engine and gearbox removed. Thankfully we have help in the shape of Tony all day.

23rd June 2014

The strip down carries on in the background and we have removed the rear lights, numberplate trim and reversing light. Bad news is that all the wrong screws have been used. Good news is that the threads are all in good condition so that will be easy to rectify.

The strip down carries on in the background and we have removed the rear lights, numberplate trim and reversing light. Bad news is that all the wrong screws have been used. Good news is that the threads are all in good condition so that will be easy to rectify.

16th June 2014

The strip down continues and this is the point when we start to forensically inspect the car. It looks like a good, rust free example but what will we find underneath the paint and inside the box sections? All the lower frame mounting bolts came undone so that is a good start as most cars rot in this area which then means a lot of complicated repair work needs doing.

The LHS door has had some dents repaired but we won't make a decision on whether we re-skin the door or repair it again until we have all the paint off. Our default position is to keep the original skin as it is easier to maintain the original fit of the door.

The strip down continues and this is the point when we start to forensically inspect the car. It looks like a good, rust free example but what will we find underneath the paint and inside the box sections? All the lower frame mounting bolts came undone so that is a good start as most cars rot in this area which then means a lot of complicated repair work needs doing.

The LHS door has had some dents repaired but we won't make a decision on whether we re-skin the door or repair it again until we have all the paint off. Our default position is to keep the original skin as it is easier to maintain the original fit of the door.

11th June 2014

Stripped out the rest of interior - only the dash to do now. The floor pans are as solid as we hoped but they will be blasted back to bare when it goes over to the paintshop.

Stripped out the rest of interior - only the dash to do now. The floor pans are as solid as we hoped but they will be blasted back to bare when it goes over to the paintshop.

10th June 2014

RHS door stripped down to bare shell. Other shots show how solid the tub is.

RHS door stripped down to bare shell. Other shots show how solid the tub is.

9th June 2014

We moved the next restoration project into the workshop today - a 1964 OTS. We supplied the car which was purchased in California so it is rust free and matching numbers. When delivered, we removed the bonnet in anticipation of the strip down to a bare shell. The brief for this an end to end restoration with some sympathetic upgrades. Colours to be confirmed but our money is on Gunmetal with red interior.....

We moved the next restoration project into the workshop today - a 1964 OTS. We supplied the car which was purchased in California so it is rust free and matching numbers. When delivered, we removed the bonnet in anticipation of the strip down to a bare shell. The brief for this an end to end restoration with some sympathetic upgrades. Colours to be confirmed but our money is on Gunmetal with red interior.....